I was interested to know if you actually disputed the microspheres could be a result of thermite use. Apparently you accept they could be but could equally be from primer paint/collisions etc?I don't know that it would. Why are you asking me?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Debunked: Iron Microspheres in 9/11 WTC Dust as Evidence for Thermite

- Thread starter Hitstirrer

- Start date

I was interested to know if you actually disputed the microspheres could be a result of thermite use. Apparently you accept they could be but could equally be from primer paint/collisions etc?

I don't think I'd say "equally", but sure, thermite probably makes iron microspheres.

Ok, so my point is, does anyone know how to differentiate them or exclude certain things like rust/primer as being the source of the microspheres which were found? I'm guessing the answer is 'no' or else it would have already come up in the debate.I don't think I'd say "equally", but sure, thermite probably makes iron microspheres.

Ok, so my point is, does anyone know how to differentiate them or exclude certain things like rust/primer as being the source of the microspheres which were found? I'm guessing the answer is 'no' or else it would have already come up in the debate.

I think the sphere enthusiasts do sometimes say that thermite spheres are distinct from other spheres, maybe more more or something (having formed from pure iron vapor)?

Some preliminary experiments with the dust indicates you can increase the microsphere content by dropping it through an open flame. The iron dust sparkles like a sparkler, and more spheres are formed - likely though a similar mechanism to the steel wool combustion.

Jay Howard

Member

B) He did not say by weight. It seems more likely to be by number. Particle frequency.

This seems like a non-controversial point, because how would they count the particles? At any rate, the standard used to measure Fe in the samples as quoted by the RJ Lee Group paper is the NIOSH 7300 which gives its results in ug/L or mg/m^3. If a percent is expressed, it therefore must be a percent by weight. This is the intuitive measurement anyway, but here is the method and the limitations of the method:

http://www.emedco.info/nmam/pdfs/7300.pdf

Now, as for the 10-100 tons of iron microspheres, I have looked for a reference without success, yet. Clearly this estimate is based on the amount of dust generated in the collapses, multiplied by the RJ Lee findings of 5.87% by weight of iron microspheres. I'll keep looking, as this is not trivial.

Jay Howard

Member

That I'm an engineer, and you obviously aren't, might have something to do with the way you have framed this response.

It matters not a wit that you are an engineer. That title does not endow infalibility nor the right to post a bunch of bare assertions.

Jazzy said:These aren't theories, but physical properties known to engineers, and other scientists.

I shall bunch these "facts" with their answers:

large amounts of iron microspheres (10-100 tons worth) - Scraping was the cause. Steel on steel, 50,000 tons of it sliding down 50 columns for nine hundred feet. Twice.

Do you have a test that corroborates this theory?

Jazzy said:molten metal - Sixty tons of duralumin airframe held in a "muffle furnace" at a temperature above 650 deg C for an hour produces "molten metal".

650C for an HOUR! Where, pray tell, did those temps obtain in the towers? According to the official report, they found no evidence for temps around that for more than 15 minutes. The burn tests included in the report confirmed this: a max temp of about 1000C for about 10 min.

jazzy said:molten concrete - Concrete is destroyed by temperatures over 800 deg C. Concrete cannot melt any more than plaster can melt, as they are materials formed by water of crystallization.

I'll defer to Mick's judgement on this. I have a feeling when you see what happened to the concrete, there will ensue a semantic debate.

Jazzy said:vaporized lead - Battery rooms destroyed by fire and collapse.

So what process are you theorizing happened here? Seriously, if I proposed such a theory to account for...whatever, everyone here would jump on it as completely unfounded, untested and unlikely. All of which would be true. To propose it here is simply dismissive of the temps in excess of 3000F necessary to vaporize lead.

Jazzy said:the steel with swiss-cheese holes in it studied by Worchester Polytechnic - Accelerated high-temperature rusting.

So where did the fuel come from for this accelerated high temp rusting? Energy is not free.

Jazzy said:the relatively low burning temp of kerosine - Irrelevant. The tower's potential energy (in just the steelwork) was equivalent to 95 tons of TNT, and could raise 1,200 tons of iron to melt.

That's true, if all the energy was used for that purpose. But it couldn't have been. In such an inefficient transfer of energy as a collapse, the vast majority of kinetic energy is expended in hitting the ground. Not controversial. How much of that energy is necessary to create the friction events necessary to create the Fe microspheres AND pulverize the concrete and pulverize the asbestos and vaporize the lead and pulverize all the MMVF and melt all the "aluminum" and throw steel girders hundreds of feet horizontally? There is an energy gap.

Jazzy said:the red-gray chips which produce Fe ms when ignited - Red oxide primer under aluminum paint would do the same. The tower steelwork was primed with red oxide primer and coated with aluminum paint.

the uniform 100 nm Fe2O3 particles in the red part of the chips - Are slightly larger than the brochure above offers you, and normal for red oxide primer paint.

No, it doesn't. It has been tested. The hydrocarbons turn black, then the paint peels off the steel due to expansion differentials in the steel vs the primer. No Fe ms. If you have some evidence to the contrary, this would be the time to produce it.

Jazzy said:Science is apparently "a set of untested, unverified and low-probability ad hoc theories". Well, bully for you.

No sir. I'm saying you are not doing science. You are throwing a bunch of untested and unrelated hypotheses out to account for a number of phenomena that can be accounted for by a single, tested, corroborated theory.

Jazzy said:Yes, I AM saying that. (Edit: same material, but the particle size for data storage is sixteen times smaller.)

Same manufacturing processes? Can you back this claim up with anything?

Jazzy said:Must I be subjected to abuse because I know information you don't? Or are you actually going to do proper research instead of merely attempting to verify your ludicrous preconceptions?

Proper research? I would love to see some to back up your battery claim. Or your friction events claim? Or your time/temp claims for melting metal? Or your "primer produces Fe ms" claim?

Jazzy, you make a bunch of claims here, but you have very little scientific ground to stand on. These are weak theories that have not been corroborated by much of anything. What reasons (other than incredulity) do you have to dismiss a working, tested theory that accounts for all these phenomena?

This seems like a non-controversial point, because how would they count the particles? At any rate, the standard used to measure Fe in the samples as quoted by the RJ Lee Group paper is the NIOSH 7300 which gives its results in ug/L or mg/m^3. If a percent is expressed, it therefore must be a percent by weight. This is the intuitive measurement anyway, but here is the method and the limitations of the method:

http://www.emedco.info/nmam/pdfs/7300.pdf

Now, as for the 10-100 tons of iron microspheres, I have looked for a reference without success, yet. Clearly this estimate is based on the amount of dust generated in the collapses, multiplied by the RJ Lee findings of 5.87% by weight of iron microspheres. I'll keep looking, as this is not trivial.

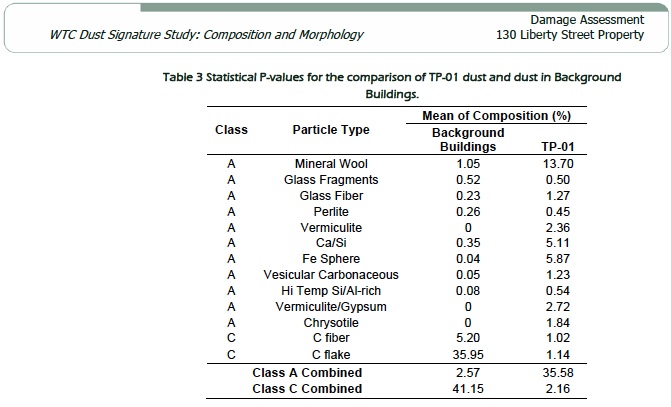

The 5.87% figure comes from here:

External Quote:

Statistical analyses were performed to compare the distribution of particle

types within TP-01 occupied spaces of the Building to those found in the

Background Buildings by various statistical methods. Background Building

samples were analyzed by SEM in the same manner as the samples collected

within the gash of the Building. The same field technicians, sampling media,

equipment, and laboratory technicians were used in all stages to minimize

variability.

The data were evaluated using a two-tailed heteroscedastic analysis of

means test. This type of test allows for unequal variances in the two

populations tested, a condition which often occurs when one population has

a substantially higher mean than the other. The statistical analysis was

conducted for each of thirteen particle types as well as for composites of

Class A and Class C particles. Eleven particle classes were derived from

major building products or were influenced by high temperature (Class A

particles). An additional two particle types included carbon-rich particles

and flakes and carbon-rich fibers such as skin, cellulose, and hair (Class C

particles). A summary of the results obtained for this analysis is provided in

Table 3.

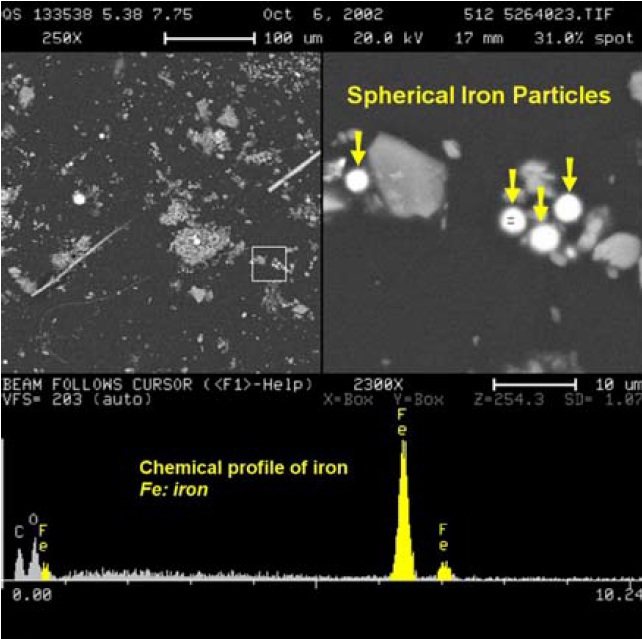

SEM+EDS is a counting technique, not a mass determination technique. You look at a picture created with SEM (Scanning Electron Microscope), and you point sample individual particle with EDS to see what they are composed of.External Quote:

Samples were analyzed for dust, particle characteristics, and WTC

Signature using scanning electron microscopy (SEM), coupled with energy

dispersive spectroscopy (EDS) techniques.

Table 3 is labeled "Statistical P-Values", and "Mean of composition (%)". I'm not clear exactly what this means

Last edited:

Jay Howard

Member

SEM+EDS is a counting technique, not a mass determination technique. You look at a picture created with SEM (Scanning Electron Microscope), and you point sample individual particle with EDS to see what they are composed of.

Mick, the 5.87% figure doesn't make any sense as "particle frequency." That is a very unscientific method to determine the "amount" of something in a dust sample for a number of reasons.

% by weight makes more sense because, mainly, it is the standard employed in the RJ Lee Group reference to NIOSH 7300. And, it is the most meaningful measurement when determining an elemental concentration. Pointing at something doesn't disambiguate its density. Without density there is no way to determine concentration. Spectroscopy is employed to disambiguate elemental composition, but some measurement of mass must be employed to make sense of relative composition.

Can we please move on to something that is in dispute?

Mick, the 5.87% figure doesn't make any sense as "particle frequency." That is a very unscientific method to determine the "amount" of something in a dust sample for a number of reasons.

% by weight makes more sense because, mainly, it is the standard employed in the RJ Lee Group reference to NIOSH 7300. And, it is the most meaningful measurement when determining an elemental concentration. Pointing at something doesn't disambiguate its density. Without density there is no way to determine concentration. Spectroscopy is employed to disambiguate elemental composition, but some measurement of mass must be employed to make sense of relative composition.

Can we please move on to something that is in dispute?

This is in dispute. I'm disputing it. How do you get weight from SEM analysis?

Jay Howard

Member

This is in dispute. I'm disputing it. How do you get weight from SEM analysis?

You don't, that I know of. As I posted above and linked, the NIOSH 7300 standard to which RJL Group defers gives results in ug/L or mg/m^3.

Now, where is your justification for "particle counting"?

You don't, that I know of. As I posted above and linked, the NIOSH 7300 standard to which RJL Group defers gives results in ug/L or mg/m^3.

Now, where is your justification for "particle counting"?

Regarding that table, they say "Statistical analyses were performed to compare the distribution of particle types". That seems to imply counting to me. i.e. they are dividing the particles up into different types of particle. It's not done at an elemental level, it's pretty clearly done by visual characterization of the particles combined with EDS inspection.

Jay Howard

Member

Regarding that table, they say "Statistical analyses were performed to compare the distribution of particle types". That seems to imply counting to me. i.e. they are dividing the particles up into different types of particle. It's not done at an elemental level, it's pretty clearly done by visual characterization of the particles combined with EDS inspection.

So we're going by what "seems to imply counting" to you? Because that doesn't seem to imply "counting" to me. And what do you mean "counting"? And how could they tell the difference between gypsum and asbestos and concrete visually? And how are they not doing elemental analysis if they're using EDS?

This is far beyond a ridiculous discussion. It's painful to have to justify to you the methods they employed for analysis--even after posting a link to their methodology in favor of "particle counting" for which there are ZERO references to the table in question. Are we really having this discussion?

I can see how 5.87% by weight of Fe ms would be disconcerting to a proponent of the official theory, but try as you might, the facts will not yield.

MikeC

Closed Account

What would "distribution of particle types" be if not counting?

As Mick has already pointed out:

As Mick has already pointed out:

SEM produces a picture of the particles so they can be identified - EDS then tells you what those particles are.External Quote:

Samples were analyzed for dust, particle characteristics, and WTC

Signature using scanning electron microscopy (SEM), coupled with energy

dispersive spectroscopy (EDS) techniques.

It's very clear that the various things in this list are not distinguishable by NIOSH 7300, which is elemental analysis. It detects individual elements, not if something is a glass fiber or a glass fragment (or even if it's glass). It can't tell you if the iron is spherical, or in flakes of iron oxide rust.

RJ Lee says:

https://www.metabunk.org/files/WTC-Dust-Signature.Asbestos.Final_.121503-1.pdf

RJ Lee says:

https://www.metabunk.org/files/WTC-Dust-Signature.Asbestos.Final_.121503-1.pdf

That means they counted 400,000 particles, by looking at 80,000 images.External Quote:

This WTC Dust evaluation represents the most extensive microscopic investigation related to WTC Dust ever performed. Over 400,000 particles were classified using SEM techniques with approximately 80,000 images collected.

Last edited:

Jazzy

Closed Account

I'm mentioning that it's the topic in question, and not some semantic exercise where I'm supposed to provide YOU with information, but one where you have to step up and learn something for yourself. I have already given you the direction.That title does not endow infalibility nor the right to post a bunch of bare assertions.

The effects of friction you will have to study up for yourself. You will need a variable-speed motor with an exposed shaft, and a steel plate, and a way of applying the plate to the shaft. It will tell you all you need to know.Do you have a test that corroborates this theory?

Fifteen minutes will do. Much of the material was 2mm thick.650C for an HOUR! Where, pray tell, did those temps obtain in the towers? According to the official report, they found no evidence for temps around that for more than 15 minutes. The burn tests included in the report confirmed this: a max temp of about 1000C for about 10 min.

No, it won't. It is already semantic. Concrete can NEVER melt, for reasons previously stated. If you don't see that, you never will. Until you learn some physics...I'll defer to Mick's judgement on this. I have a feeling when you see what happened to the concrete, there will ensue a semantic debate.

Liquid lead has its own vapor pressure, hence will emit vapor. Also, impact will vaporize liquid lead, if only by rapidly increasing its surface area.So what process are you theorizing happened here? Seriously, if I proposed such a theory to account for...whatever, everyone here would jump on it as completely unfounded, untested and unlikely. All of which would be true. To propose it here is simply dismissive of the temps in excess of 3000F necessary to vaporize lead.

The fuel required to lift the material into place at the moment when it was constructed. It would have been diesel fuel.So where did the fuel come from for this accelerated high temp rusting? Energy is not free.

No. A third of it was used up on the way down, damaging the previously-undamaged structure, creating the friction microspheres, etc.That's true, if all the energy was used for that purpose. But it couldn't have been. In such an inefficient transfer of energy as a collapse, the vast majority of kinetic energy is expended in hitting the ground.

I've just answered that.Not controversial. How much of that energy is necessary to create the friction events necessary to create the Fe microspheres AND pulverize the concrete and pulverize the asbestos and vaporize the lead and pulverize all the MMVF

That would have been the burning jet fuel and office materials.and melt all the "aluminum"

That would be the buckling process.and throw steel girders hundreds of feet horizontally?

You haven't shown this. Please do so.There is an energy gap.

You are describing fire, not friction. I'm fresh out of 900 foot tall steel columns, primed and painted, to slide 2,000 tons of steel down. How about you? Best get back to the motor, shaft, plate idea, eh?No, it doesn't. It has been tested. The hydrocarbons turn black, then the paint peels off the steel due to expansion differentials in the steel vs the primer. No Fe ms. If you have some evidence to the contrary, this would be the time to produce it.

I'm advising you to regard the scientific understanding of potential energy, friction, buckling, and the effects of heat on materials as your first priority, and not semantics.No sir. I'm saying you are not doing science. You are throwing a bunch of untested and unrelated hypotheses out to account for a number of phenomena that can be accounted for by a single, tested, corroborated theory.

Why don't you check for yourself? It's an observation, not a "claim". Really...Same manufacturing processes? Can you back this claim up with anything?

I would charge you for the service, but I'm busy relaxing and swimming in the sea. I am no longer a physics teacher, and when I was, I was recompensed for it. It seems to me that you have to prove your claims to me, and not the other way round.Proper research? I would love to see some to back up your battery claim. Or your friction events claim? Or your time/temp claims for melting metal? Or your "primer produces Fe ms" claim?

In a nutshell you have to prove that the microspheres found could only have been produced by thermite, and you aren't going to be able to prove that except by showing the presence of a material unique to thermite, and not found in the materials of the building. I don't believe there is one, and so you're done. The thread will only demonstrate how little you know and understand, which is a good thing.

A sure knowledge that you don't know what you're talking about, either in respect of my "claims", but also, sadly, in the case of yours.Jazzy, you make a bunch of claims here, but you have very little scientific ground to stand on. These are weak theories that have not been corroborated by much of anything. What reasons (other than incredulity) do you have to dismiss a working, tested theory that accounts for all these phenomena?

If you first investigate the potential energy "claim" properly, I feel sure you'll lose the need to bother with your own. But will you?

Last edited:

Jay Howard

Member

What would "distribution of particle types" be if not counting?

As Mick has already pointed out:

External Quote:

Samples were analyzed for dust, particle characteristics, and WTC

Signature using scanning electron microscopy (SEM), coupled with energy

dispersive spectroscopy (EDS) techniques.

The term "distribution" can refer to any mathematical function that can be measured for comparison. Counting the number of objects is a weak bit of information because it makes no differentiation in particle size. If it's particle counting, then a lot of small particles can weigh as much as a single large particle, and yet the distribution curve would make it seem like there was more of the little particle material. A distribution curve such as this could be useful with the addition of some more info in mapping relative particle sizes, perhaps, but not very useful in diagnosing the relative amounts of the various substances.

This is elementary. But here we are.

MikeC said:SEM produces a picture of the particles so they can be identified - EDS then tells you what those particles are.

And ICPAES produces elemental content and mass.

The term "distribution" can refer to any mathematical function that can be measured for comparison. Counting the number of objects is a weak bit of information because it makes no differentiation in particle size. If it's particle counting, then a lot of small particles can weigh as much as a single large particle, and yet the distribution curve would make it seem like there was more of the little particle material. A distribution curve such as this could be useful with the addition of some more info in mapping relative particle sizes, perhaps, but not very useful in diagnosing the relative amounts of the various substances..

They were entirely uninterested in determining the weight. They just wanted to determine a signature. Particle frequency was what they used.

Jay Howard

Member

I'm mentioning that it's the topic in question, and not some semantic exercise where I'm supposed to provide YOU with information, but one where you have to step up and learn something for yourself. I have already given you the direction.

I'm not the one making outlandish claims about the origins of these various phenomena. If I was, I would be expected to back my claims up.

Jazzy said:The effects of friction you will have to study up for yourself. You will need a variable-speed motor with an exposed shaft, and a steel plate, and a way of applying the plate to the shaft. It will tell you all you need to know.

Why would I test a theory I don't think holds any water whatsoever?

Jazzy said:Fifteen minutes will do. Much of the material was 2mm thick.

So it went from an hour to fifteen minutes?! We're doing science now.

Jazzy said:Liquid lead has its own vapor pressure, hence will emit vapor. Also, impact will vaporize liquid lead, if only by rapidly increasing its surface area.

What does this have to do with the lead that precipitated on the mineral wool found by RJ Lee?

Jazzy said:The fuel required to lift the material into place at the moment when it was constructed. It would have been diesel fuel.

Diesel fuel caused rapid, high-temperature oxidation and sulfidation to the steel? I'd love to see your corroborative evidence for this. Secondly, there are at least 2 pieces of steel with these unusual burn characteristics. One was found from WTC7, the other from either WTC 1 or 2. Separate events. Separate places. Diesel caused both of them?

Jazzy said:No. A third of it was used up on the way down, damaging the previously-undamaged structure, creating the friction microspheres, etc.

This really is at the center of your microsphere theory. Do you have any way to demonstrate this other than with an angle grinder? Have you seen any work showing the similarities or differences in the WTC microspheres and those created from friction? Why are you so willing to adopt a theory without the slightest bit of confirmation from ANYWHERE? Yet you are quick to dismiss a tested, corroborated theory that has some dangerous implications.

It makes it seem as though your interest is not so much with the scientific results but with political agendas. Please correct me if I'm wrong. Do you have a good scientific reason to dismiss the existing nano-energetic compound theory of Fe ms creation?

Jazzy said:That would have been the burning jet fuel and office materials.

Right.

Jazzy said:That would be the buckling process.

Handwaved away. No test. No corroborative evidence. Just an armchair theory to be accepted as truth from an authority.

Jazzy said:You haven't shown this. Please do so.

Show me how diesel can cause rapid, high-temperature oxidation and sulfidation and I'll retract my statement.

Jazzy said:You are describing fire, not friction. I'm fresh out of 900 foot tall steel columns, primed and painted, to slide 2,000 tons of steel down. How about you? Best get back to the motor, shaft, plate idea, eh?

No, the peeling primer paint is from an increase of heat--not from a fire. The test was performed in an oven, not an open flame. Regardless of what may or may not have occured in the towers, the red-gray chips form Fe ms when ignited. The primer paint does not. No amount of wishful thinking or ignoring evidence will change this.

Jazzy said:Why don't you check for yourself? It's an observation, not a "claim". Really...

Because again, I'm not the one making the claim. I think it's a low-probability and redundant theory. They theory I subscribe to is tested and the tests confirm it. Why would I need to account for phenomena if they've already been accounted for by a single theory that explains ALL of the various phenomena?

Jazzy said:I would charge you for the service, but I'm busy relaxing and swimming in the sea. I am no longer a physics teacher, and when I was, I was recompensed for it. It seems to me that you have to prove your claims to me, and not the other way round.

If the discussion is cutting into your lifestyle, you are under no obligation to participate. But if you put forth a theory that is intended to account for the phenomena we are discussing, then it doesn't seem like much to ask for you to make sense of your own theory.

If I claim that the buildings fell because of a mini-nuke, should I not be required to corroborate that theory with something? According to you, I can just ask you to do your own test and get back to me.

Cairenn

Senior Member

It seems that you choose to ignore any evidence that doesn't agree with your belief and you refuse to do a simple experiment that would allow you to see the truth for yourself. It seems that the only 'evidence' you will accept is what verifies your own belief.

If that is so, I don't understand why you are here.

If that is so, I don't understand why you are here.

Jazzy

Closed Account

You are making an outlandish claim, of course: that steel microspheres found were NOT made by collapsing steel towers.I'm not the one making outlandish claims about the origins of these various phenomena. If I was, I would be expected to back my claims up.

Because you have no interest in real truth at all. Just your unstated agenda.Why would I test a theory I don't think holds any water whatsoever?

Yes. We observe that section thickness affects speed of melting in a high heat flux environment.So it went from an hour to fifteen minutes?! We're doing science now.

Mineral wool would indeed pick up lead vapor from an environment containing it. Unsurprisingly.What does this have to do with the lead that precipitated on the mineral wool found by RJ Lee?

Yes.Diesel fuel caused rapid, high-temperature oxidation and sulfidation to the steel? I'd love to see your corroborative evidence for this. Secondly, there are at least 2 pieces of steel with these unusual burn characteristics. One was found from WTC7, the other from either WTC 1 or 2. Separate events. Separate places. Diesel caused both of them?

Had it not been burnt, the steel wouldn't have been lifted, and gifted all that potential energy. Without that potential energy, the steel wouldn't have had kinetic energy when it struck Gzero. Without that kinetic energy it wouldn't have become HOT. Without being hot, it wouldn't have corroded so rapidly in an aqueous environment.

Because it is in my experience. I have made the calculations, I have carried out the processes (or taken steps to avoid them). I have seen all these stages occur.This really is at the center of your microsphere theory. Do you have any way to demonstrate this other than with an angle grinder? Have you seen any work showing the similarities or differences in the WTC microspheres and those created from friction? Why are you so willing to adopt a theory without the slightest bit of confirmation from ANYWHERE? Yet you are quick to dismiss a tested, corroborated theory that has some dangerous implications.

You are wrong. You have been consistently wrong. Nothing you have written is correct at all. It's YOUR political agenda.It makes it seem as though your interest is not so much with the scientific results but with political agendas. Please correct me if I'm wrong.

No.Do you have a good scientific reason to dismiss the existing nano-energetic compound theory of Fe ms creation?

But I wouldn't accept it either, knowing that in ball-park terms, any such material would be "drowned in the noise" created when thousands of tons of steel SLID at 120 mph over A MILLION SQUARE FEET OF STEEL SURFACES.

Of course.That would have been the burning jet fuel and office materials. Right.

Established engineering IS "corroborative evidence".Handwaved away. No test. No corroborative evidence.

But for your entertainment note here the huge lateral acceleration given to the center of this column as it buckles.

Since 1745 AD. I accept it.Just an armchair theory to be accepted as truth from an authority.

Had it not been burnt, the steel wouldn't have been lifted, and gifted all that potential energy. Without that potential energy, the steel wouldn't have had kinetic energy when it struck Gzero. Without that kinetic energy it wouldn't have become HOT. Without being hot, it wouldn't have corroded so rapidly in an aqueous environment.Show me how diesel can cause rapid, high-temperature oxidation and sulfidation and I'll retract my statement.

Retract it.

So nobody prepared a primed and painted steel surface and ran heavily-loaded steel at 120 mph over it? Then what exactly do you think they were testing?No, the peeling primer paint is from an increase of heat--not from a fire. The test was performed in an oven, not an open flame. Regardless of what may or may not have occured in the towers, the red-gray chips form Fe ms when ignited. The primer paint does not. No amount of wishful thinking or ignoring evidence will change this.

It's science.Because again, I'm not the one making the claim. I think it's a low-probability and redundant theory.

Because you aren't interested in science?They theory I subscribe to is tested and the tests confirm it. Why would I need to account for phenomena if they've already been accounted for by a single theory that explains ALL of the various phenomena?

Not in the case of science - which isn't 'my theory', by-the-way.If the discussion is cutting into your lifestyle, you are under no obligation to participate. But if you put forth a theory that is intended to account for the phenomena we are discussing, then it doesn't seem like much to ask for you to make sense of your own theory.

http://en.wikipedia.org/wiki/Buckling

http://en.wikipedia.org/wiki/Electrochemistry#Iron_corrosion

I'm not making any claim except that you haven't addressed the science of the collapses at all, and by not doing so you have already rendered your claim (whatever it is) facile.If I claim that the buildings fell because of a mini-nuke, should I not be required to corroborate that theory with something? According to you, I can just ask you to do your own test and get back to me.

The frictional area of the tower tops falling into the towers was more than a million square feet, and engineers know (amongst each other at least), that dry loaded and unlubricated steel surfaces sliding past each other at great speeds make SPARKS. Not only that, but by doing so, they take up atmospheric oxygen. By doing that the sparks may then solidify as spheres of the pure material, through surface tension, and in an oxygen-depleted environment. And the pure material, carbon steel, IS nearly pure iron. And that a cubic centimeter of iron can make many billions of billion-atom microspheres.

And any coating material of finely ground iron oxide powder over aluminum powder (that is being the primed and painted surface of the tower steel) would DEFINITELY have ignited if it found itself stuck to a white-hot blob of iron. Nobody ever said that primer on its own would ignite (but you). It is already fully oxidized.

Science has no politics. I'd say thank God, were I not an atheist.

Last edited:

dunbar

Active Member

How does the steel's fireproofing play with the friction hypothesis? I read somewhere that Underwriters Lab performed a test of the fireproofing by firing 12 gauge shotgun rounds into it at close range. If I remember correctly the fireproofing was stripped at a rate 15 rounds per square meter, fairly tough and durable stuff to say the least.

Jay Howard

Member

It seems that you choose to ignore any evidence that doesn't agree with your belief and you refuse to do a simple experiment that would allow you to see the truth for yourself. It seems that the only 'evidence' you will accept is what verifies your own belief.

If that is so, I don't understand why you are here.

I think you're misunderstanding how the various theories rank in their ability to deal with the evidence in totality. If I had been under a rock for the past 13+ years and had to decide which theory or set of theories best describes the forensic evidence at hand, this is what I would be considering:

1. 3 steel framed buildings collapse in less than 30 seconds each

2. Evidence of vaporized lead precipitating on mineral wool

3. Photographic and eyewitness evidence of molten metal

4. At least 2 pieces of steel from separate locations (WTC7 and either WTC 1 or 2) with high-temp corrosion and sulfidation burns leaving a "swiss cheese" resemblance

5. Abundant iron-based microspheres in the dust

6. Steel girders thrown hundreds of feet horizontally

7. Red-gray chips found in the dust which produce an exothermic spike in heat (a mini explosion) and whose by-product is iron-based microspheres

8. Red-gray chips have within them uniform 100 nm Fe2O3 particles, which were built from a "bottom up" method

One theory says the red-gray chips were the cause of all the other high-heat evidence and played some role in the destruction of the towers.

The other set of theories goes something like this:

1. To be expected from the massive plane crashes and fires that ensued.

2. Caused from a floor filled with batteries, which have liquid lead in them. When the planes crashed, the already liquid metal vaporized (from increasing the surface area mostly) and precipitated on the mineral wool and elsewhere.

3. It's all aluminum which only needs 15 minutes at 650C to liquify at smaller gauges.

4. The kinetic energy of dropping steel from 1300 feet into an aqueous environment can cause rapid, high-heat oxidation and sulfidation.

5. Caused from all the steel scraping against itself on the way down.

6. Also caused from the kinetic energy of the falling steel.

7. It's primer paint. Primer paint does that. Even though it doesn't do that when tested. It did that when the buildings fell because they were unusual circumstances.

8. It's primer paint. Quit asking questions. You're making yourself look silly.

Now, which theory or set of theories makes more sense to you?

Jazzy

Closed Account

The only effect it might have is to lubricate it somewhat. A mica/cement/binder that could be blown off by a thermobaric blast is hardly going to interfere with thousands of tons of steel accelerating up to 120 mph.How does the steel's fireproofing play with the friction hypothesis? I read somewhere that Underwriters Lab performed a test of the fireproofing by firing 12 gauge shotgun rounds into it at close range. If I remember correctly the fireproofing was stripped at a rate 15 rounds per square meter, fairly tough and durable stuff to say the least.

Friction isn't "a hypothesis". The floors of the tower were moving downwards while the core columns were not. There had to be friction. Even allowing for half the frictional area to be missed, and conceding that slow speeds produced less microspheres, the collapsing towers had to create between five and fifty tons of them.

3 steel framed buildings collapse in less than 30 seconds each - if that had been their free fall collapse time they would have been 44,145 feet tall. If you mean ten seconds per, you are wrong in every case.

Evidence of vaporized lead precipitating on mineral wool - which is entirely without consequence.

Photographic and eyewitness evidence of molten metal - the plane was melted by the fire it was within. Office equipment is made from several low-melting-point alloys.

steel with a "swiss cheese" resemblance - had rotted by accelerated aqueous corrosion.

Abundant iron-based microspheres in the dust - Caused by friction during collapse.

Steel girders thrown horizontally - consequent to buckling.

Red-gray chips - Are 'silver' paint on red oxide primer.

Red-gray chips have within them uniform 100 nm Fe2O3 particles - Are 'silver' paint on ordinary red oxide primer.

One theory says the red-gray chips were the cause of all the other high-heat evidence - but unfortunately this theory ignores the potential energy of the towers which could raise 1200 tons of steel to melt.

To be expected from the massive plane crashes and fires that ensued - you are only correct because you are quoting me, and not misquoting me.

Caused from a floor filled with batteries, which have liquid lead in them. When the planes crashed, the already liquid metal vaporized (from increasing the surface area mostly) and precipitated on the mineral wool and elsewhere - is gibberish. Lead-acid batteries don't have liquid lead in them, and that isn't what I wrote at all. Vapors of metals in air become dusts as fast as steam becomes condensation. Any wool will pick them up. There was a 2000 sq.ft battery room immediately beneath the fire in WTC2.

It's all aluminum which only needs 15 minutes at 650C to liquify at smaller gauges - duralumin is an alloy of aluminum and copper. It does indeed melt in a furnace, and the towers were furnaces where their fires were burning. This plane was made of duralumin sheet materials. The fire had been burning for less than an hour when molten metal appeared at the outside of the tower just beneath where the plane wreckage was entirely surrounded by fire.

The kinetic energy of dropping steel from 1300 feet into an aqueous environment can cause rapid, high-heat oxidation and sulfidation - is also gibberish, and not at all what I wrote. Sulphidation I never mentioned, but would indeed be part of the oxidative process I was writing about.

{Friction) caused from all the steel scraping against itself on the way down - Yes, a million square feet of frictional area, and tons of microspheres.

(Lateral ejection) caused from the kinetic energy of the falling steel. - that's right. You are only correct because you are quoting me, and not misquoting me.

It's primer paint. Primer paint does that. (Burn). Even though it doesn't do that when tested - Primer paint will not do it because it is already oxidized. It would be nice if you took care not to deliberately misrepresent nearly everything I write. Aluminum ("silver") paint and red oxide primer will burn if heated together to white heat.

I wouldn't go around calling science 'a theory' if I were you.Now, which theory or set of theories makes more sense to you?

I guess it goes with all your other lies and misrepresentations. Good luck when someone else bites you in the ass, which they are bound to do while you stick to the same tune, and fail to do proper research.

And misrepresent. And tell lies.

Last edited:

dunbar

Active Member

Friction isn't "a hypothesis".

Technically true in the sense that friction was undoubtedly a factor, but friction is very much still just a hypothesis in terms of the question: is friction alone an adequate explanation for the abundance of ms observed? The answer is: I'm not so sure, you'll have to make a technical demonstration in order to support your hypothesis. And as of yet, no such technical demonstration has been made. It's just another unsupported, unsubstantiated, naked assertion that we are expected to just go with on the rationale of 'What else could it possibly be?'.

Jazzy

Closed Account

This is what's known as a "Fermi calculation".Technically true in the sense that friction was undoubtedly a factor, but friction is very much still just a hypothesis in terms of the question: is friction alone an adequate explanation for the abundance of ms observed? The answer is: I'm not so sure, you'll have to make a technical demonstration in order to support your hypothesis. And as of yet, no such technical demonstration has been made. It's just another unsupported, unsubstantiated, naked assertion that we are expected to just go with on the rationale of 'What else could it possibly be?'.

There are two towers. There are 47 columns in a tower core. Assume they are 4' x 2'. Assume a mean fall distance of nine hundred feet.

So the friction area (of steel scraped to produce microspheres) will be 2 x 12 x 47 x 900 = 1,015,200 square feet = 100,000 square meters appx.

Assume half the area was missed at any one time*, but half a millimeter was scraped off for the rest of the time, and you would get 50 cubic meters of microspheres. Seems like too much for me. so let's try 0.1 mm of scrape-off**. This gets you ten cubic meters (80 TONS) of microspheres.

We know that a cubic centimeter gives fifteen hundred billion billion-atom-microspheres, so ten cubic meters of billion-atom microspheres would be about fifteen thousand trillion of them.

Roughly... What's good enough for Enrico is good enough for me.

No "such technical demonstration" needs to be "made".

Is it really an "unsupported, unsubstantiated, naked assertion"?

Are you really expected to just go with on the rationale of 'What else could it possibly be?'

Are you really going to deny friction during the tower's fall?

* Best not to go further than that, because dynamic forces would have closed in on the flooring impinging upon ever-largening columns, serving to increase the frictional loads over time. The speed was increasing over time, of course.

** 0.1mm is a very small amount - about four thousandths of an inch.

Last edited:

dunbar

Active Member

AFAIK no-one has never said that friction is only factor - so your "objection" is just a strawman.

If I have misrepresented or misinterpreted it wasn't intentional and I apologize. I was responding to this post in particular:

There had to be friction. Even allowing for half the frictional area to be missed, and conceding that slow speeds produced less microspheres, the collapsing towers had to create between five and fifty tons of them.

Abundant iron-based microspheres in the dust - Caused by friction during collapse.

{Friction) caused from all the steel scraping against itself on the way down - Yes, a million square feet of frictional area, and tons of microspheres.

I was not aware that any supplementary explanations had been suggested.

dunbar

Active Member

No "such technical demonstration" needs to be "made".

Is it really an "unsupported, unsubstantiated, naked assertion"?

Are you really expected to just go with on the rationale of 'What else could it possibly be?'

Are you really going to deny friction during the tower's fall?

I don't deny friction, but as I understand it the formation of the ms in question requires tremendous heat. I don't deny friction or that friction produces heat, but I am doubtful that this friction could have produced the necessary heat required for the formation of ms of elemental iron. I think what you would likely end up with from this mere friction

Now are simple iron filings found in the dust? If so then Jazzy has done an excellent job of explaining their presence.

dunbar

Active Member

I think the sphere enthusiasts do sometimes say that thermite spheres are distinct from other spheres, maybe more more or something (having formed from pure iron vapor)?

I believe the claim made by Jones, Harrit , and Farrer is that a portion of the spheres are iron rich or pure elemental iron that can only form at temperatures well in excess of those supposed to have been reached within the building. The iron rich spheres are differentiated from iron oxide spheres by their chemical composition.

The USGS makes the same distinction in their particle atlas but says that the particles are difficult to distinguish:

The Particle Atlas of World Trade Center Dust

External Quote:

Metal and Metal-Oxide Phases

The primary metal and metal-oxide phases in WTC dust are Fe-rich and Zn-rich particles (Meeker and others, 2005b). Many other metal and metal oxide phases have been identified including phases rich in Al, Ti, Pb, Bi, Mo, Zr, Sn, Cu, and others. It is often difficult to distinguish between metals and metal oxides with qualitative EDS because of adsorbed surface oxygen or thin coatings of oxide phases such as rust. It is impossible to distinguish metals and metal-oxides with qualitative EDS analysis using a Be window x-ray detector.

In order to distinguish Mo-, Pb-, and Bi- rich phases it is necessary to look for additional M, L, and K series peaks. This may require higher accelerating voltages to excite these x-ray energies. If additional M, L, or K series peaks are not observed, these elements are probably not present and the peak occurring near ~2.3 keV can be attributed primarily to S.

http://pubs.usgs.gov/of/2005/1165/508OF05-1165.html#heading08

Jazzy

Closed Account

Friction can produce temperatures up to plasma levels at relatively low speeds. The rate of fall achieved by the towers was similar to the surface speed of a grinding wheel, and the sliding steel would have produced SPARKS, which being white hot, would have been liquid steel, and therefore spherical. I would concede iron filings for a few moments following the onset of collapse, while the kinetic energy available was low.I don't deny friction, but as I understand it the formation of the ms in question requires tremendous heat. I don't deny friction or that friction produces heat, but I am doubtful that this friction could have produced the necessary heat required for the formation of ms of elemental iron. I think what you would likely end up with from this mere frictionis simple microscopic iron filings. Now are simple iron filings found in the dust? If so then Jazzy has done an excellent job of explaining their presence.

One cc of these microspheres, assuming they were billion-atom-microspheres, would number fifteen hundred billion…

The proportion of carbon in low-carbon structural steel is 0.2 %. This proportion of carbon is almost too low to accurately measure, and approximates to pure iron. Pardon me while I wait for a refutable truther claim...

Last edited:

Jazzy

Closed Account

Supposed to have been reached by fire, no doubt. But friction is an entirely different case.I believe the claim made by Jones, Harrit , and Farrer is that a portion of the spheres are iron rich or pure elemental iron that can only form at temperatures well in excess of those supposed to have been reached within the building.

No. They say they can't differentiate them - "It is impossible to distinguish metals and metal-oxides with qualitative EDS analysis using a Be window x-ray detector".The iron rich spheres are differentiated from iron oxide spheres by their chemical composition.

Unremarkable. What interests you here?The USGS makes the same distinction in their particle atlas but says that the particles are difficult to distinguish:

The Particle Atlas of World Trade Center DustExternal Quote:

Metal and Metal-Oxide Phases

The primary metal and metal-oxide phases in WTC dust are Fe-rich and Zn-rich particles (Meeker and others, 2005b). Many other metal and metal oxide phases have been identified including phases rich in Al, Ti, Pb, Bi, Mo, Zr, Sn, Cu, and others. It is often difficult to distinguish between metals and metal oxides with qualitative EDS because of adsorbed surface oxygen or thin coatings of oxide phases such as rust. It is impossible to distinguish metals and metal-oxides with qualitative EDS analysis using a Be window x-ray detector.

In order to distinguish Mo-, Pb-, and Bi- rich phases it is necessary to look for additional M, L, and K series peaks. This may require higher accelerating voltages to excite these x-ray energies. If additional M, L, or K series peaks are not observed, these elements are probably not present and the peak occurring near ~2.3 keV can be attributed primarily to S.

http://pubs.usgs.gov/of/2005/1165/508OF05-1165.html#heading08

dunbar

Active Member

Friction can produce temperatures up to plasma levels at relatively low speeds. The rate of fall achieved by the towers was similar to the surface speed of a grinding wheel, and the sliding steel would have produced SPARKS, which being white hot, would have been liquid steel, and therefore spherical.

Perhaps friction can produce temperatures up to plasma levels, but given the nature of the collapse I'm not so certain that there was sufficient sustained friction in either amount, intensity, or duration to account for any significant portion of the ms.

No. They say they can't differentiate them - "It is impossible to distinguish metals and metal-oxides with qualitative EDS analysis using a Be window x-ray detector".

Well apparently Harrit has been successful in this area:

External Quote:

In several spheres, elemental iron was verified since the iron content significantly exceeded the oxygen content. We conclude that a high-temperature reduction-oxidation reaction has occurred

http://www.globalresearch.ca/active...-9-11-world-trade-center-catastrophe/?print=1

Just the fact that the USGS acknowledges that there is a distinction to be made, nothing more.Unremarkable. What interests you here?

I think you need the full context there:

http://www.globalresearch.ca/active...-9-11-world-trade-center-catastrophe/?print=1

This does not seem unexpected for rust/paint chips that have been scraped off a metal surface. They will likely contain some steel filings, which will burn and create iron microspheres.

http://www.globalresearch.ca/active...-9-11-world-trade-center-catastrophe/?print=1

A DSC is a Differential Scanning Calorimeter (which you can just think of as an oven for this). Harrit took the chips, presumably dropped them into a 700C environment, at which point they ignited, and claimed to find iron-rich spheroids in the result.External Quote:8. After igniting several red/gray chips in a DSC run to 700 °C, we found numerous iron-rich spheres and spheroids in the residue, indicating that a very high temperature reaction had occurred, since the iron-rich product clearly must have been molten to form these shapes. In several spheres, elemental iron was verified since the iron content significantly exceeded the oxygen content. We conclude that a high-temperature reduction-oxidation reaction has occurred in the heated chips, namely, the thermite reaction.

This does not seem unexpected for rust/paint chips that have been scraped off a metal surface. They will likely contain some steel filings, which will burn and create iron microspheres.

Last edited:

Jazzy

Closed Account

That's fair.Dunbar said:Well apparently Harrit has been successful in this area

External Quote:In several spheres, elemental iron was verified since the iron content significantly exceeded the oxygen content. We conclude that a high-temperature reduction-oxidation reaction has occurred

http://www.globalresearch.ca/active...-9-11-world-trade-center-catastrophe/?print=1

The friction that created these high-temperature and reducing particles took place in a relatively confined space - between contacting metal surfaces - so the chances are the high-temperature reduction was that brought about by the iron being oxidized removing oxygen from the local environment, causing it to become a reducing environment. There's a sort of verification in a loose admission of there being surplus oxygen around*.

Of course, one can imagine that some people might see aluminum as being that reducing partner. But from what we see here that's not necessary. Especially as it doesn't seem to be present.

* If aluminum had been in the vicinity in surplus there would have been no loose oxygen or oxide coating.

Last edited:

Jazzy

Closed Account

This does not seem unexpected for rust/paint chips that have been scraped off a metal surface. They will react anyway, as Fe2O3 and aluminum powders will. You should read the Zeppelin Disaster report.I think you need the full context there:

http://www.globalresearch.ca/active...-9-11-world-trade-center-catastrophe/?print=1

A DSC is a Differential Scanning Calorimeter (which you can just think of as an oven for this). Harrit took the chips, presumably dropped them into a 700C environment, at which point they ignited, and claimed to find iron-rich spheroids in the result.External Quote:8. After igniting several red/gray chips in a DSC run to 700 °C, we found numerous iron-rich spheres and spheroids in the residue, indicating that a very high temperature reaction had occurred, since the iron-rich product clearly must have been molten to form these shapes. In several spheres, elemental iron was verified since the iron content significantly exceeded the oxygen content. We conclude that a high-temperature reduction-oxidation reaction has occurred in the heated chips, namely, the thermite reaction.

This does not seem unexpected for rust/paint chips that have been scraped off a metal surface. They will likely contain some steel filings, which will burn and create iron microspheres.

Jay Howard

Member

You are making an outlandish claim, of course: that steel microspheres found were NOT made by collapsing steel towers.

Again, let's go over the facts and decide like rational people what outlandish claims are being made.

1. Iron-based microspheres found in abundance in the WTC dust?

YES

2. Red-gray chips found in the WTC dust which have uniform 100 nm Fe2O3 particles?

YES

3. Red-gray chips ignite at relatively low temp, spike in energy release, and leave Iron-based ms as by-product?

YES

4. Other evidence of high-temperature reactions that occurred during the WTC event?

YES

How then, is it outlandish to theorize that the red-gray chips are the likely cause of the iron-based ms found in the WTC dust?

On the other hand, you claim without a shred of evidence, not a single reference to an experiment that confirms your theory, not any kind of work that examines the size, composition or structure of debris created by friction compared to the WTC ms, that FRICTION is the primary reason for the ms and any further looking at anything else as a possible explanation is stupid and futile.

It's important to note here that the "nano-energetic compound" theory, for which you are so feverishly dismissing as even a possible explanation, is able to account for ALL the other "anomalous" phenomena for which you must employ several unrelated, untested theories to account for. From a scientific perspective, your "shotgun-of-theories" approach of low-probability, untested claims sits in low rank against a single, tested theory which accounts for the TOTALITY of evidence.

Your stubborn refusal to see the logic in this can only be taken as purposeful.

Jazzy said:Because you have no interest in real truth at all. Just your unstated agenda.

Or perhaps a theory exists that's been tested and corroborated by those tests which accounts for the TOTALITY of evidence. Perhaps.

Jazzy said:Yes. We observe that section thickness affects speed of melting in a high heat flux environment.

At first, it's an hour to produce the molten metal, then, after pointing out that no such time/temp officially existed, it's FIFTEEN MINUTES! Like I said, now we're doing science.

Jazzy said:Mineral wool would indeed pick up lead vapor from an environment containing it. Unsurprisingly.

But by what means did the lead in question become liquid? Phase changes require energy. A lot of it to go from solid to vapor. Your answer to the "vaporized lead" problem is as obscure as it is improbable. Please show me how stupid I am and walk me through the convoluted process by which you hypothesize the lead got to 1749C (3180F).

Jazzy said:Had it not been burnt, the steel wouldn't have been lifted, and gifted all that potential energy. Without that potential energy, the steel wouldn't have had kinetic energy when it struck Gzero. Without that kinetic energy it wouldn't have become HOT. Without being hot, it wouldn't have corroded so rapidly in an aqueous environment.

Let me make sure I'm understanding you correctly: This is what the FEMA/BPAT performance assessment Appendix C said about the steel in question:

"Evidence of a severe high temperature corrosion attack on the steel, including oxidation and sulfidation with subsequent intergranular melting was readily visible in the near-surface structure. A liquid eutectic mixture containing primarily iron, oxygen and sulfur formed during this hot corrosion attack on the steel. This sulfur-rich liquid penetrated preferentially down grain boundaries of the steel severely weakening the beam and making it susceptible to erosion."

And you account for this by saying that this steel fell in an "aqueous environment" while hot, right? No corroborative evidence. No attempt to replicate the phenomenon. No source for the elemental sulfur--and we know there was elemental sulfur from the EDX spectroscopy that show S and no Ca in the steel. Again, your theory does very little to get us closer to an answer for all these phenomena, just a veil of doubt designed to discourage a unified explanation of these data sets. Or as you call it, "science."

Jazzy said:No.

But I wouldn't accept it either, knowing that in ball-park terms, any such material would be "drowned in the noise" created when thousands of tons of steel SLID at 120 mph over A MILLION SQUARE FEET OF STEEL SURFACES.

You haven't given one single bit of reason to accept the "friction" hypothesis at all, at all, much less as a better theory to explain the microspheres. As such, your basic position Begs the Question at hand. This is one of the basic mistakes that differentiates science from other activities (like sales and persuasion): the process of scientific discovery does NOT entail a conclusion, but looks at the TOTALITY of evidence in order to produce the most powerful explanation of the phenomena at hand. You are not doing science, no matter how high you claim to be on your ivory tower.

Jazzy said:Had it not been burnt, the steel wouldn't have been lifted, and gifted all that potential energy. Without that potential energy, the steel wouldn't have had kinetic energy when it struck Gzero. Without that kinetic energy it wouldn't have become HOT. Without being hot, it wouldn't have corroded so rapidly in an aqueous environment.

Retract it.

You haven't shown anything. Demonstrate how hot plate steel forms a "liquid eutectic" when thrown into an aqueous environment or admit you're just throwing out an armchair hypothesis which has no scientific merit.

Jazzy said:So nobody prepared a primed and painted steel surface and ran heavily-loaded steel at 120 mph over it? Then what exactly do you think they were testing?

It's science.

Sure it is. So let's unpack your stance with the inclusion of this new theory of ms creation. Your position is that the iron ms were created by the friction of steel on steel AND by steel friction from the primer paint? But with addition of this new theory, (no surprise) you have no corroborative evidence for this. The only test I point to that results in primer paint peeling off steel at high temps, you claim is not a test for what you hypothesize. Ok. But where is the test that confirms your hypothesis? Oh yea, it doesn't exist. Science.

Jazzy said:The frictional area of the tower tops falling into the towers was more than a million square feet, and engineers know (amongst each other at least), that dry loaded and unlubricated steel surfaces sliding past each other at great speeds make SPARKS. Not only that, but by doing so, they take up atmospheric oxygen. By doing that the sparks may then solidify as spheres of the pure material, through surface tension, and in an oxygen-depleted environment. And the pure material, carbon steel, IS nearly pure iron. And that a cubic centimeter of iron can make many billions of billion-atom microspheres.

And any coating material of finely ground iron oxide powder over aluminum powder (that is being the primed and painted surface of the tower steel) would DEFINITELY have ignited if it found itself stuck to a white-hot blob of iron. Nobody ever said that primer on its own would ignite (but you). It is already fully oxidized.

So again, here you have a lot of confidence in your theories, but absolutely zero corroborative testing confirming your hypotheses. No spectroscopy done to compare the elemental composition of ms created by friction vs. aluminothermic reactions. No micrographic comparison of friction ms vs WTC ms. Nada. The only test comparing the properties of primer paint to the red-gray chips shows them to perform very differently under increased temps: Namely, the red-gray chips demonstrate an explosive spike in energy release AND leave iron-based microspheres as a by-product. The primer paint eventually just peels off the steel. No explosive spike in energy release, no iron microspheres.

To a scientist, that would be enough to give good reason to rethink the idea that these red-gray chips are primer paint. But you still cling to this idea as if it settled the question of origin of the WTC ms. It doesn't even have any merit whatsoever. Your position is based entirely on wishful thinking and self-proclaimed authority. But that just doesn't cut it in the real world of evidence and data-set corroboration.

Jazzy said:Science has no politics. I'd say thank God, were I not an atheist.

Closer to the truth to say "Science shouldn't have any politics, but all science is done by people. And people have politics." That's why we need external standards of theory adequacy, which indeed, we do. One principle of theory adequacy says the theory that explains the most phenomena and ignores the least is the most powerful theory. Another says that theories that can be repeated by independent parties are better than theories that cannot be repeated. As it stands, the "nano-energetic compound" theory of WTC ms creation is better by leaps and bounds than any other attempt at explanation. And again, the biggest barriers to this theory are the psychological boundaries in accepting the implications of the red-gray chips.

Jay Howard

Member

A DSC is a Differential Scanning Calorimeter (which you can just think of as an oven for this). Harrit took the chips, presumably dropped them into a 700C environment, at which point they ignited, and claimed to find iron-rich spheroids in the result.

This does not seem unexpected for rust/paint chips that have been scraped off a metal surface. They will likely contain some steel filings, which will burn and create iron microspheres.

I think your summary of the test is basically correct. They put these chips in a very precise oven--increasing the temperature at a slow, constant rate. They ignite at 430C (806F) and produce an energy spike and Fe microspheres. The same test was performed on primer paint on steel and no spike in energy, no Fe microspheres.

Why do these tests (if done properly and I'm representing the results correctly) not disconfirm your claim that the red-gray chips are primer paint?

Your position is one of attempting to get at the truth, right? I have to ask, on what grounds are you rejecting the "nano-energetic compound" theory of iron-based microsphere creation?

Similar threads

- Replies

- 2

- Views

- 3K

- Replies

- 129

- Views

- 22K

- Replies

- 25

- Views

- 5K

- Replies

- 18

- Views

- 7K