NIST REPORT ES.3.

Eventually, the fires reached the northeast region of the building. The probable collapse sequence that caused the global collapse of WTC 7 involved the initiation of the buckling of a critical interior column in that vicinity. This column had become unsupported over nine stories after initial local fire-induced damage led to a cascade of local floor failures. The buckling of this column led to a vertical progression of floor failures up to the roof, and led to the buckling of adjacent interior columns to the south of the critical column. An east-to-west horizontal progression of interior column buckling followed, due to loss of lateral support to adjacent columns, forces exerted by falling debris, and load redistribution from other buckled columns. The exterior columns then buckled as the failed building core moved downward, redistributing its loads to the exterior columns. Global collapse occurred as the entire building above the buckled region moved downward as a single unit. This was a fire-induced progressive collapse, also known as disproportionate collapse, which is defined as the spread of local damage, from an initiating event, from element to element, eventually resulting in the collapse of an entire structure, or a disproportionately large part of it.

Factors contributing to the building failure were: thermal expansion occurring at temperatures hundreds of degrees below those typically considered in design practice for establishing structural fire resistance ratings; significant magnification of thermal expansion effects due to the long-span floors, which are common in office buildings in widespread use; connections that were designed to resist gravity loads, but not thermally induced lateral loads; and a structural system that was not designed to prevent fire-induced progressive collapse.

Even without the structural damage, WTC 7 would have collapsed from fires having the same characteristics as those experienced on September 11, 2001.

2.3. Page 19

Even though available images showing fires in WTC 7 did not allow the detailed description of fire spread that was possible for the WTC towers, there was sufficient information to derive general descriptions of fire ignition and spread on various floors of the building (NIST NCSTAR 1-9, Chapter 5). It must be kept in mind that the fire observations were based on images of the exterior faces, which provided little indication about the behavior of fires well removed from the exterior walls. It is likely that much of the burning took place beyond the views of the windows. Relatively little smoke was seen emanating from the windows on the north face, even when flames were observed, indicating that the hot combustion products were not exhausting through the nearest openings, but instead were passing through the building interior to other exits. The wind direction was from the north, and since there would have been office furnishings spread across the tenant spaces, some of the air would have penetrated to the building interior and supported combustion of the furnishings located there. Features of this interior burning were reconstructed from the computer simulations of the fires, as described in NIST NCSTAR 1-9, Chapter 9.

Fires broke out on at least 10 floors of WTC 7, near the damaged southwest corner of the building (NIST NCSTAR 1-9, Chapter 5). They were typically observed as single floor fires, and observations supported a local fire origin on an given floor.

The early fire on each floor was small, probably involving a single cubicle or office. On the floors which were mostly furnished with clusters of cubicles (such as Floors 7 and 8), the initial fire spread would have been by flame contact with an adjacent cubicle within the cluster. Once a cluster was burning, a nearby cubicle, across an aisle, would have been ignited by thermal radiation from the flames. By the time this second cluster was fully involved, the prior cluster would have passed its peak burning rate. The path of the fires would likely have jumped from cluster to cluster, meandering toward the windows, toward the building core, or parallel to the façade. Eventually, the upper air layer over enough of the large open space would have become hot enough for the thermal radiation from the hot air to have heated and ignited multiple cubicles simultaneously, leading to faster fire growth.

Between roughly 2:00 p.m. and the collapse of WTC 7 at 5:20:52 p.m., fires were observed spreading on the 7th floor through the 13th floor, with the exception of the 10th floor. Since the collapses of the towers had resulted in the loss of city water that was the sole supply for the automatic sprinkler system on the lower 20 floors of WTC 7, these fires continued to spread unabated. All of these fires reached the northeast sector of the building between approximately 3:00 p.m. and 4:00 p.m. The intensities of the fires on the 11th, 12th, and 13th floors were higher than those on the 7th, 8th, and 9th floors because of the higher loading of combustibles and a larger burning area. There was also a small fire on the north side of the vacant 14th floor shortly before the collapse of the building. There was no visual evidence of fires on other floors, other than near the debris-damaged southwest corner of the building.

7th Floor

The fire on the 7th floor spread in a clockwise direction. Shortly after 2:00 p.m., there was a fire on the west side of the 7th floor, spreading north along the west face. The fire turned the northwest corner and by 3:00 p.m. was spreading east across the north face. Around 3:15 p.m., the fire, which had passed the midpoint of the north face, stopped and died down. About an hour later, the fire appeared a little fartherto the east, then died down by 4:40 p.m. Although no further images were available, it is likely that the fire continued to burn toward the east.

8th Floor

The 8th floor fire also spread clockwise. At about 3:40 p.m., a broad fire was first seen spreading east from the center of the north face. A few minutes later, there was a fire on the north end of the west face, suggesting that the fire had burned at the interior of the floor, initially bypassing the northwest corner, then burning back to that corner after the fire became established on the north face. The fire on the north face spread rapidly eastward, reaching the east face around 3:55 p.m., and then burned intensely on the east face. Soon after 4:00 p.m., the observable burning near the center of the north face had died down.

9th Floor

There were no indications of fire on the 9th floor until shortly before 4:00 p.m., when a small fire appeared on the west side of the north face. The fire grew rapidly and spread to the east, reaching the midpoint of the north face by around 4:10 p.m. Ten minutes later, the fire was halfway to the northeast corner, but by 4:38 p.m., there were only spot fires visible, located on the east side of the north face.

11th Floor

The fire on the 11th floor generally spread counterclockwise. Fire was first observed at 2:08 p.m. at the south end of the east face. Over the next 20 min, the fire spread slowly northward to the midpoint of the east face. Over the next two hours, images showed no burning. At 5:09 p.m., the fire reappeared near the center of the north face, spreading slowly to the west and not reaching the northwest corner when WTC 7 collapsed at 5:21 p.m. In the meantime, at 4:38 p.m., a fire appeared spreading east from the center of the north face, once again suggesting that the prior burning had progressed along the interior of the building before backtracking to combust furnishings near the perimeter. By 4:52 p.m., the observable flames in the area had died down.

12th Floor

The fire on the 12th floor followed a path similar to that of the fire on the 11th floor, but with different timing. Fire was first seen on the 12th floor at 2:08 p.m., toward the south end of the east face. Further south on this face, the window glass was still intact, indicating that this fire had burned in the building interior as it turned the southeast corner. By around 2:30 p.m., the visible flames had diminished, but the fire had spread both south into the southeast corner and north, reaching two-thirds of the way to the northeast corner. By 3:00 p.m., the fire had spread internally past the northeast corner and onto the north face. In less than 15 min, the fire simultaneously spread rapidly to the east to engulf the northeast corner of the floor and more slowly westward about one-third of the way across the north face. The fire continued spreading westward in starts and stops, approaching the northwest corner of the floor around 3:45 p.m. At around 5:00 p.m., the fire had reached the northwest corner.

13th Floor

Like the fires on the 11th and 12th floors, fire on the 13th floor also moved counterclockwise. Fire was seen at about 2:30 p.m. on the east side of the floor. Somewhat later, smoke and flames were coming from windows across much of the east face. Around 3:41 p.m., the fire had turned the northeast corner and was one-fourth of the way across the north face. Soon after 4:00 p.m., flames had reached at least to the midpoint of the north face; and at 4:38 p.m., the fires to the east had died down to the point where they could no longer be observed. Around 5:00 p.m., there was intense burning to the west of the center of the north face. A couple of minutes prior to the collapse of the building at 5:20:52 p.m., flames jetted from windows in the same area, indicating that there had been fire toward the interior of the floor.

14th Floor

A fire was seen briefly on the north face of the 14th floor, about halfway between the midpoint and the northeast corner, at 5:03 p.m. No fire was evident in images taken a few minutes before and a few minutes after this time.

2.4 THE PROBABLE COLLAPSE SEQUENCE

The following is the NIST account of how the fires in WTC 7 most likely led to the building's collapse.

The collapse of WTC 1 damaged seven exterior columns, between Floors 7 and 17 of the south and west faces of WTC 7. It also ignited fires on at least 10 floors between Floors 7 and 30, and the fires burned out of control on Floors 7 to 9 and 11 to 13. Fires on these six floors grew and spread since they were not extinguished either by the automatic sprinkler system or by FDNY, because water was not available in WTC 7. Fires were generally concentrated on the east and north sides of the northeast region beginning at about 3 p.m. to 4 p.m.

As the fires progressed, some of the structural steel began to heat. According to the generally accepted test standard, ASTM E-119, one of the criteria for establishing the fire resistance rating for a steel column or floor beam is derived from the time at which, during a standard fire exposure, the average column temperature exceeds 538 °C (1000 °F) or the average floor beam temperature exceeds 593 °C (1100 °F). These are temperatures at which there is significant loss of steel strength and stiffness. Due to the effectiveness of the SFRM, the highest column temperatures in WTC 7 only reached an estimated 300 °C (570 °F), and only on the east side of the building did the floor beams reach or exceed about 600 °C (1100 °F). The heat from these uncontrolled fires caused thermal expansion of the steel beams on the lower floors of the east side of WTC 7, primarily at or below 400 deg C (750 deg F), damaging the floor framing on multiple floors.

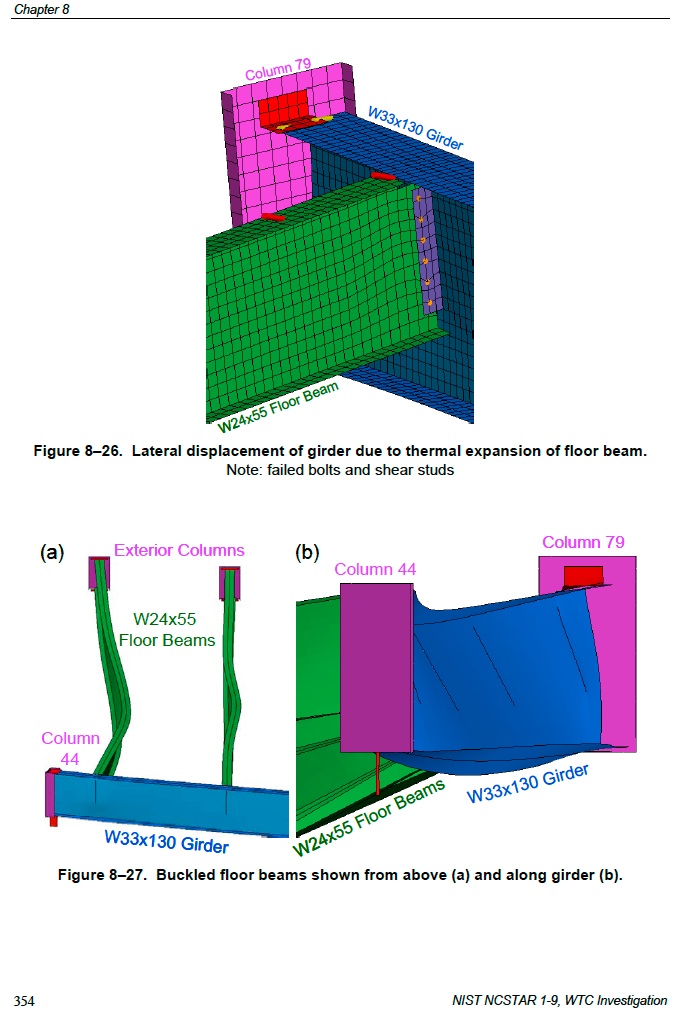

The initiating local failure that began the probable WTC 7 collapse sequence was the buckling of Column 79. This buckling arose from a process that occurred at temperatures at or below approximately 400 °C (750 °F), which are well below the temperatures considered in current practice for determining fire resistance ratings associated with significant loss of steel strength. When steel (or any other metal) is heated, it expands. If thermal expansion in steel beams is resisted by columns or other steel members, forces develop in the structural members that can result in buckling of beams or failures of connections.

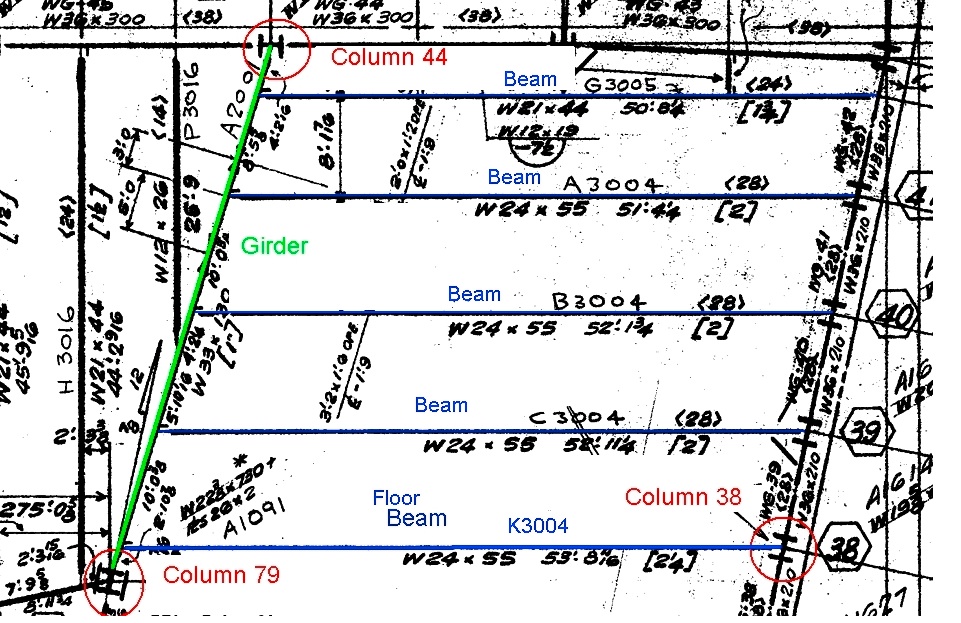

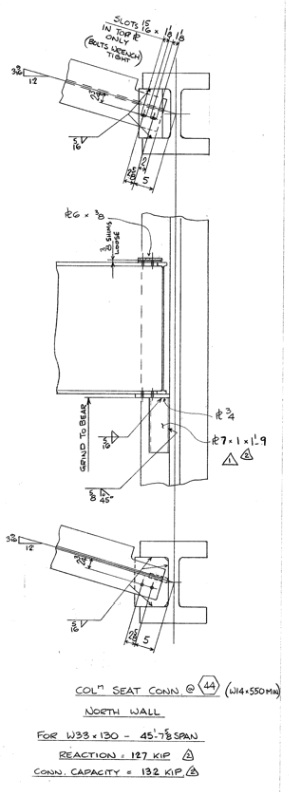

Fire-induced thermal expansion of the floor system surrounding Column 79 led to the collapse of Floor 13, which triggered a cascade of floor failures. In this case, the floor beams on the east side of the building expanded enough that they pushed the girder spanning between Columns 79 and 44 to the west on the 13th floor. (See Figure 1–5 for column numbering and the locations of girders and beams.) This movement was enough for the girder to walk off of its support at Column 79.

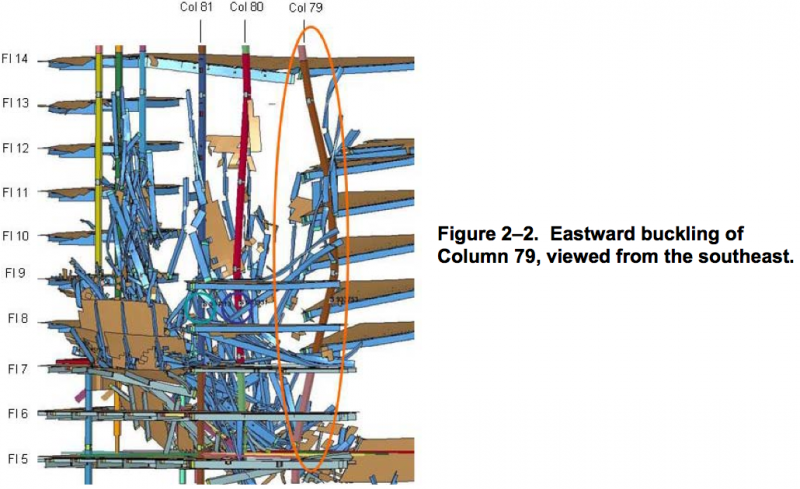

The unsupported girder and other local fire-induced damage caused Floor 13 to collapse, beginning a cascade of floor failures down to the 5th floor (which, as noted in Section 1.2.3, was much thicker and stronger). Many of these floors had already been at least partially weakened by the fires in the vicinity of Column 79. This left Column 79 with insufficient lateral support, and as a consequence, the column buckled eastward, becoming the initial local failure for collapse initiation.

Figure 2–2. Eastward buckling of Column 79, viewed from the southeast.

Due to the buckling of Column 79 between Floors 5 and 14, the upper section of Column 79 began to descend. The downward movement of Column 79 led to the observed kink in the east penthouse, and its subsequent descent. The cascading failures of the lower floors surrounding Column 79 led to increased unsupported length in, falling debris impact on, and loads being re-distributed to adjacent columns; and Column 80 and then Column 81 buckled as well. All the floor connections to these three columns, as well as to the exterior columns, failed, and the floors fell on the east side of the building. The exterior façade on the east quarter of the building was just a hollow shell.

The failure of the interior columns then proceeded toward the west. Truss 2 (Figure 1–6) failed, hit by the debris from the falling floors. This caused Column 77 and Column 78 to fail, followed shortly by Column 76. Each north-south line of three core columns then buckled in succession from east to west, due to loss of lateral support from floor system failures, to the forces exerted by falling debris, which tended to push the columns westward, and to the loads redistributed to them from the buckled columns. Within seconds, the entire building core was buckling.

The global collapse of WTC 7 was underway. The shell of exterior columns buckled between the 7th and 14th floors, as loads were redistributed to these columns due to the downward movement of the building core and the floors. The entire building above the buckled-column region then moved downward as a single unit, completing the global collapse sequence.