Course they also forgot that the surrounding structural members were physically in the path of that failure. But thats a whole other issue I think we should take up separately.

No, here will do. It's the fundamental issue here.

The floor, heated from beneath, would sag initially merely due to the temperature gradient across it. Later on it would tend to straighten, were it not for the fact it was halving its tensile strength,

and creeping. When tied together through the columns to all the other floor elements its "center" would move in the direction of any opening in the floor. It would also be trying to squirm (up or down) due to being under compression by the cold, non-expanded exterior periphery.

A hot loaded column, as Column 79 certainly was, would have had plenty of time over seven hours to sag vertically down (allowing everything it supported to do mostly the same) and distort sideways to follow this movement, being at a temperature 125 deg C above its creep transition point.

Being out-of-line in such a manner would have made it extremely prone to buckling collapse: Euler's Law refers to classically vertical/horizontal structures only. Two consecutive collapsed floors would put it past critical even if it were straight.

You have to account for nine or ten inches

too much of compressed steel/concrete across the floor plane, with the periphery in tension. I think that if C79's centerline were to be five inches out-of-vertical, then floor collapse and column buckling might well be a simultaneous event.

This could easily happen if the fire moved through the building. Consider one side of the floor already up to temperature, sagging and pulling. Then if the fire crossed to the other side it could heat the floor, causing it to expand before it began to sag. That would create a powerful sideways push on the central columns. This process was observed in the tower fires, where first the floors expanded, pushing the external columns outwards, then they crept and sagged, pulling the same columns inwards.

Uneven heating of the steel causes bending long before it has a chance to expand linearly. One side heats and the other does not, the response of the beam is to bend, without much if any push.

I've already told you that.

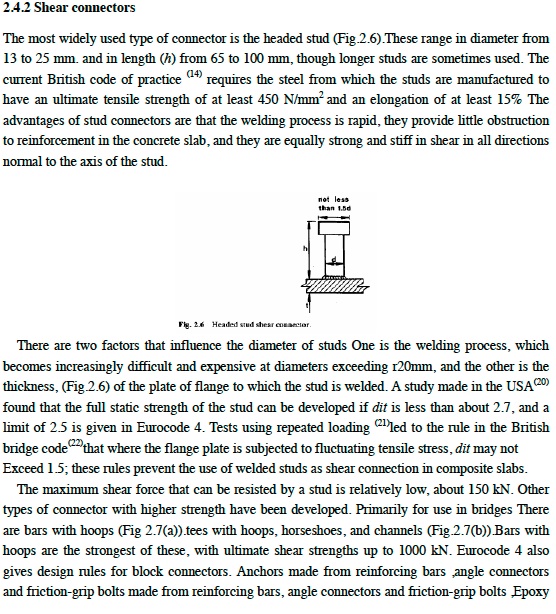

It's impossible without the studs, never mind with them. As Boston said, concrete and steel have similar thermal expansion coefficients, the difference is in their ability to conduct heat. I think a good way to think of the function of the studs is to make the floor system act as one element ie composite.

I've already told you that.

NIST supposed that the steel heated up, but the concrete didn't. This sets up a differential thermal expansion between them and would allow them to ignore the composite nature of the floor system.

They didn't at all.

You cannot stop steel expanding and if it is held in place either at the ends or also with studs it would go into compression.

I've already told you that.

The issue here is that NIST played down the studs on the beams. Studs on the girder is a different issue.

Neither issue is important.

Who is to say that there were not studs

The studs aren't an issue.

we allowed for no resistance due to shear studs and the connection still did not fail.

I've already told you that.

That the girder did or didn't have shear studs makes no difference, but I would still reckon it would have them. The floorpan installer would agree with this, as would every other engineer i have ever managed to speak to about this. It is common sense that the floor would be made composite by their use.

I've already told you that.

But just to be clear, before i go further, you now accept that every floor beam to the east of the connection had shear studs on it?

The studs aren't an issue.

They tie the slab system to the support system. Creating a monolithic construct that acts as one unit under load.

I've already told you that.

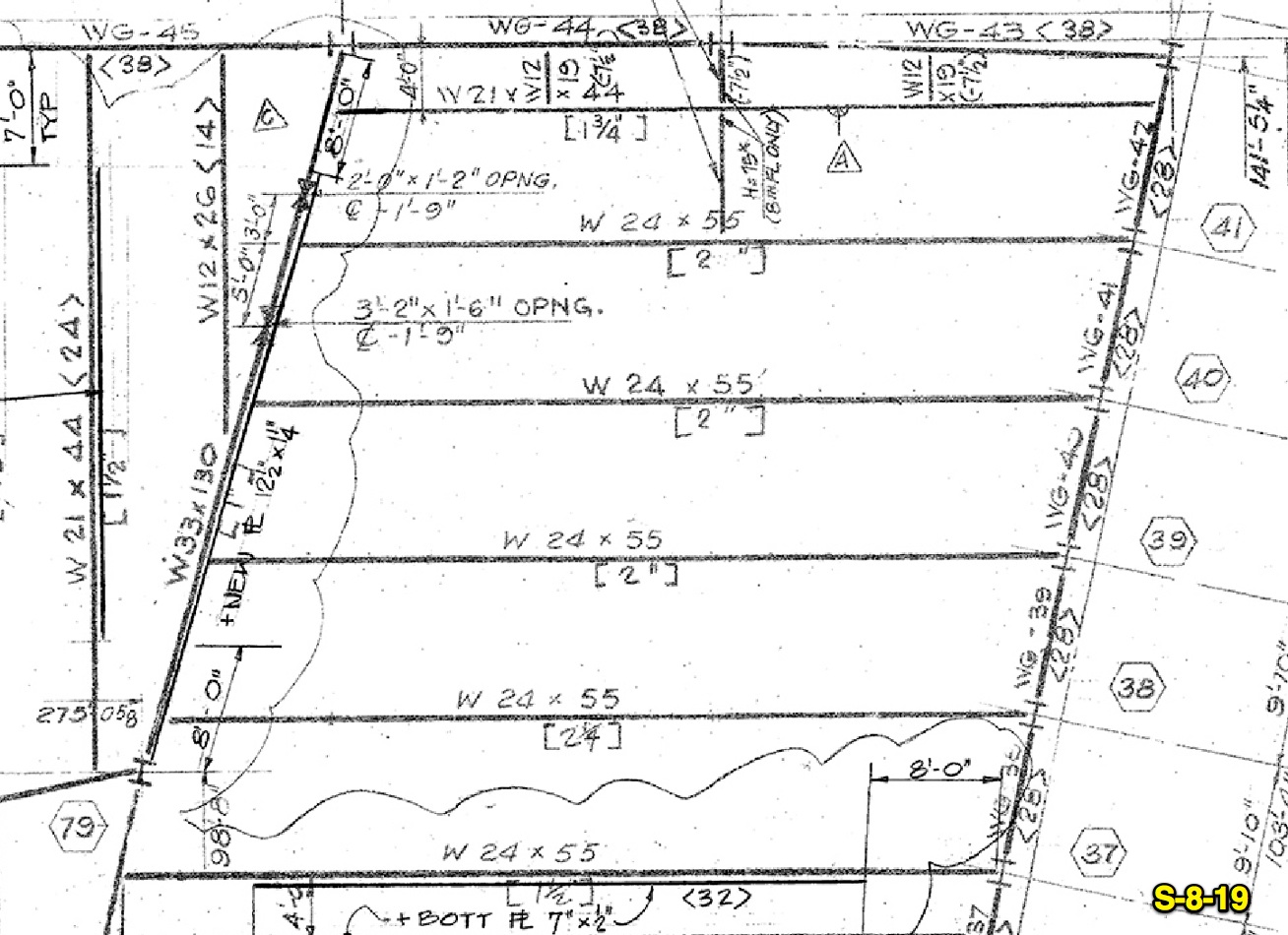

Weak? that last drawing showed an awful lot of shear studs, represented by all those numbers between the <> brackets. The effect of these studs is to create a monolithic structure between the slab and the supporting structure, it also serves to radiate heat between the two evening out the thermal expansion should there be any. NIST corrected that plate size yet didn't modify its hypothesis to account for it.

The monolithic structure is quite probably that which caused column 79 to fail.

I'm going to suggest because the hypothesis simply doesn't work once this correction is made.

I don't believe that that is their hypothesis. If it was, it never worked anyway.

They would need more heat to expand the steel further to knock it off this larger seat. They formerly argued that any additional heat than what they originally predicted would result in sagging rather than pushing. So how is it you can call this line of reasoning weak?

This line of reasoning is totally weak, because it addresses nothing more than ONE SIDE OF THIS COLUMN.

Yeah, we did that, we also did some animations. What I personally think would happen is that the girder would probably go into compression, expand into the column and end up being trapped by the side plates on the side of the column. which overlap the edge. From above it would look something like this.

Except that apparently there's an

invisible partition allowing the floor to the right to be heated, and nothing at all happening to the left of column 79.

There proudly stands column 79, perfectly erect and unaffected by seven hours at 600 deg C.

The girders to the right expand without sagging (well, you wouldn't see it from above, eh?) so they never pulled a thing.

The girders to the left never expanded, perhaps at a different time, and never pushed as those on the right pulled.

Is that your idea of a timeline?

Your "animation" is altogether and absolutely irrelevant. Got any more?

If not I have some concrete and a sledgehammer to crush it up with. Go play a cool hand.