Pete Tar

Senior Member

Ha, well I was just going on the posts made and the tone therein, I was hoping the video's were the same.You should check the supporting videos.

Ha, well I was just going on the posts made and the tone therein, I was hoping the video's were the same.You should check the supporting videos.

But once the restraint was relaxed on column 79, a pandora's box of consequences was opened.All this is good stuff very informative but I fail to see the evidence that would have suggested or proved simultaneous failure to cause the period of free fall. I get that it could fall onto itself with the momentum and weight but where is there something explaining how the period of free fall could be possible. Because if you think about it IF thermite were used the only places they would need to use it would be the spots critical to cause the free fall gravity would do the rest as proven above

Buckling failure is characterized by silence, and a rapid acceleration to free fall tempered only by the resistance to bending of the column. It is very nearly free fall.Totally agree the process would have been swift and unrecognizable to the human eye, unfortunately it just doesn't give any evidence for the period of free fall.

No. It is exactly to the point. Buckling, when it occurs would only be recoverable if you had a spare column standing to one side which could take up the load it has just rejected. Otherwise it is as sure as death.And the argument that the collapse would have started before we think it did although it may seem to make sense it really is just smoke and mirrors in the debate of the speed of the collapse because the "collapse" technically started when the fires did if your thinking about it like that.

I haven't used any maths at all so far. You have the cart before the horse. It was already as weak as it could be and still remain erect, immediately before it failed. You are a victim of a form of Zeno's Paradox. http://en.wikipedia.org/wiki/Zeno's_paradoxesWe know math proves the building or any building could fall as fast or close to as fast as it did. But it doesn't show in any way that everything would weaken so simultaneous or close enough to it to create free fall speed especially with being able to slow the video down and examine it so closely, it's clearly a synchronized fall I just don't think the math and physics explains the actual problem of this collapse.

Promising. That's the cry who doesn't understand - yet. It certainly isn't my intention to confuse you. I want you to see.I've read a few of jazzy postings and although obviously informed most of what I have seen on this particular issue from you are technicalities that don't explain the real problem and mostly just try to confuse anyone who disagrees.

The free fall of the fascia was a classic buckling failure. It occurred beneath the image frame when sufficient floors had piled up to cut all restraint to the exterior.The simultaneous collapse and period of free fall are the problems not the collapse itself although still very coincidental

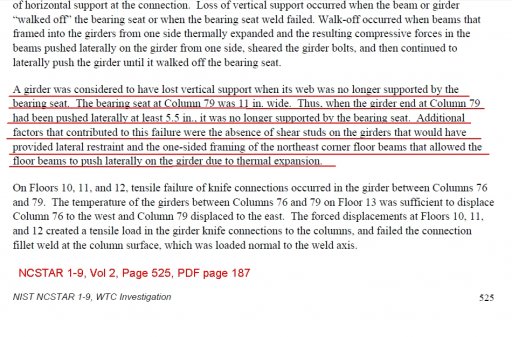

I think it was NIST who were overly fixated on this girder. They supposed that the whole area heated to 600 deg evenly, and we took that to have happened in our analysis. Steel will begin to sag over 600 which would render them to have lost just under half of their tensile strength. Looking at their animations their failure of column 79 is totally unrealistic, and had they included the correct dimensions and elements would have been even more impossible. I would imagine that the main transfer truss systems would have to fail, but I cannot accept that the failure of one column (79) could possibly cause a building to fail in this way. We recently did an analysis of their statements from 2008 re the issue which may be of interestI suspect you have over-fixated on the single beam.

The whole floor was heated, presumably from beneath, and all the beams (and column 79) were expanding, and sagging, and at half their original strength.

Considering the whole floor as a plane surface, its outside was constraining and cold, and strong, and its interior was weakening, while attempting to expand and sag between its column supports.

Where column 79 (and for that matter, any column) stood, there was a battle of forces. I agree with NIST that C79 was probably where the battle was fiercest.

Studs cannot take much beam sagging because tremendous leverage is exerted when the beam ends are angled. They too were at half-strength at 600 deg C.

I take it you accept that once C79 wasn't laterally fixed, and at half-strength, its Euler stability was compromised. Then you have to accept that the beams also had their own Euler stability.

So, even if the beam next to C79 hadn't walked off its support, what sort of instance may cause it to do so? I will suggest an answer to this: the failure of the studs by sagging beam leverage.

This could have been a failure elsewhere. The floor was already unstable, being restrained by its outsides. The exterior was in tension, the interior was under compression, wanting to walk up or down. The whole was elastic, like so many springs, and the shock loads caused by the sudden release of a fixing point would have been transmitted around it.

Exactly what was the trigger, no-one will ever know. Exactly how the sequence played out, no-one will ever know*.

It's a dynamic and three-dimensional problem poorly addressed by both you and NIST, but much more poorly by you, because they managed a realistic simulation.

And I believe it.

* Such situations being ideal traps for the religious.

.

Couldn't agree more with this. The technical issues need to be addressed seperate from any political or ideological issues in order that we learn from what happened that day. Refreshing that this seems to be a forum that is capable of achieving this. Kudos for that.I have no comment on the technical accuracy of what you're putting forward - I am illiterate in this conversation, but I would like to say that this is the way to present an argument against the official story - no hyperbole, no ideology, no mention of Gulf of Tonkin or mind-control by mainstream media, just the brass-tacks.

It's refreshing - even if you turn out to be mistaken.

I'll follow with interest.

My point is that an amateur could tell the difference between 11" and 1 foot, i am sure you can. And I apologise if I was short with you.

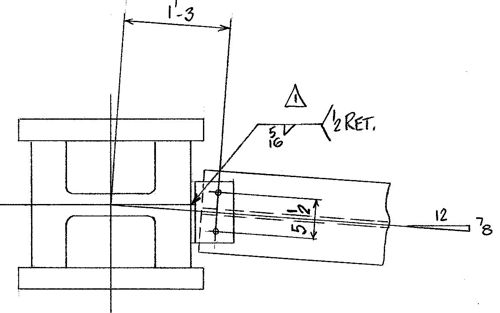

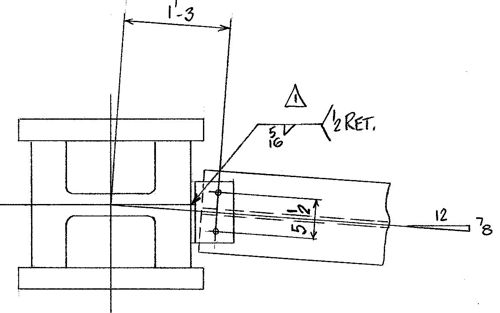

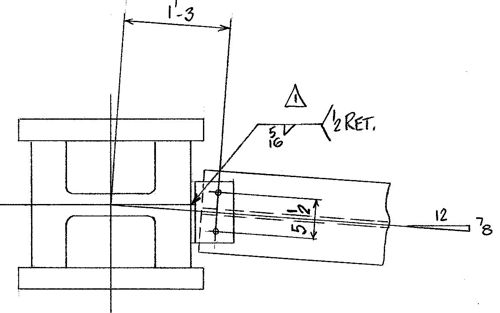

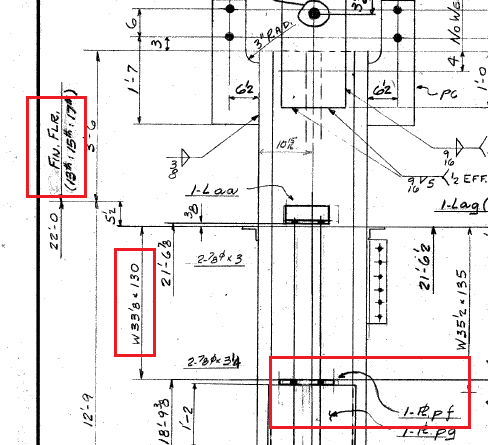

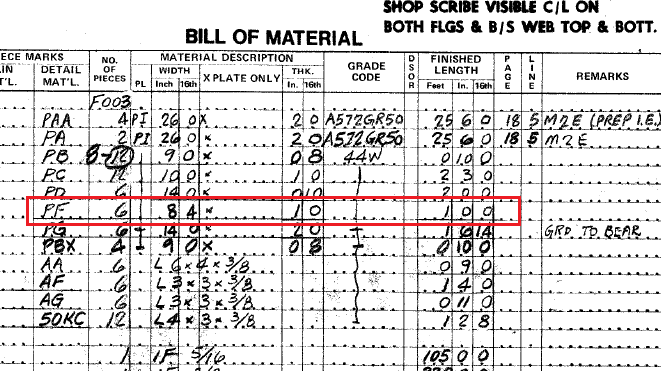

Yes, I would go along with that, there's a bit more to it obviously, but all in all, a pretty good summary. Thanks.So basically, you're claiming in your videos that the way column 79's girder was set up means that thermal expansion could not have happened to a degree necessary for displacing it. You say that this is because of structural components that NIST overlooked including platforms that added to the distance necessary for the girder to "walk" off of its platform as well as other pieces that added rigidity to the girder and that the thermal expansion calculations included an incorrect change in temperature value and failed to account for the aforementioned structural components. Furthermore, you say that the girder would not have been able to walk the distance needed to fall off of its platform under any circumstances since the temperature needed for such expansion would have caused the steel to sag before anything else. Just so that everybody who is not able to watch the videos is all on the same page with you, is this a good summary of what you are claiming?

I would enjoy an intellectually honest discussion of this issue without the logical fallacy. You say......But once the restraint was relaxed on column 79, a pandora's box of consequences was opened.

The first consequence was that column 79 buckled. The load it was supporting was everything above it. It stopped accepting it. It shed its load. It would have squirmed sideways as it did so. By it, I mean the column length between the ceiling of that floor, and the floor beneath. The doubling of its effective length would have automatically quartered its resistance to Euler Buckling.

That meant the weight of everything above it had to be supported (including its own, through column/beam connections with their studs, and without cross-bracing) all the way to the roof by its neighbors, which were fifty feet away.

The next consequence would have been the unattached floor striking the floor beneath. If that happened to break its connections, the effective length of that section of Column 79 would have been tripled, and its resistance to buckling reduced to one ninth.

This was not a static process. Nor was it slow. Buckling failure is silent and rapid, and involves very little resistance once it occurs. C79 would have thrashed like a snake, and every attached floor above it would also have been rapidly detached, more or less simultaneously. This would be something similar to, but not quite, free fall.

Even so, the video's claim of collapse taking 6 seconds is incorrect by a factor of TWO. It took TWELVE seconds to collapse completely. The penthouse disappearing before the fascia began to move is the clue to that.

Or, in other words, the WTC7's collapse began six seconds before you believe it did. The building emitted a large puff of black smoke (caused by a falling floor).

This marked the start of collapse.

Hello Mike, the bill of materials posted earlier in this thread shows a plate that is clearly 1' and NIST said it was 11" to suit their thermal expansion nonsense. Sorry, for some reason i cannot get it to post here. It's on post#21.Indeed - but I don't know where to look for that, why it is relevant, and what you conclude from it.

Perhaps I'm a bit old fashioned, but I'd like to see het points laid out clearly and preferably in print - the videos do nothing for me in that respect I'm sorry.

Maths fight!...I would rather not have a maths peeing contest with you...

Maths fight!

Better that than the usual devolving to political rhetoric and evangelising that usually takes place in a 9-11 standoff.

The initial query as to whether you are going to get this work published in a proper peer-journal (which you reacted to based on the phrase 'amateur debunkers' which wasn't about you but the audience of armchair experts that plague the internet) should be seriously considered. No prize for convincing people on a forum, but making a convincing case that stands up to scrutiny by engineers would be something else.

Hello Mike, the bill of materials posted earlier in this thread shows a plate that is clearly 1' and NIST said it was 11" to suit their thermal expansion nonsense. Sorry, for some reason i cannot get it to post here. It's on post#21.

Wrong. During the massive renovation in 1989, they were able to remove columns and almost entire floors without there be any threat to the structural integrity of the building. That's what the building's inbuilt redundancy (i.e., if multiple columns and massive sections of floors are lost or removed, the weight of everything above shifts into standing/undamaged columns) allowed for.But once the restraint was relaxed on column 79, a pandora's box of consequences was opened.

The first consequence was that column 79 buckled. The load it was supporting was everything above it. It stopped accepting it.

http://www.nytimes.com/1989/02/19/r...uilding-within-building-cost-200-million.htmlExternal Quote:BEFORE it moves into a new office tower in downtown Manhattan, Salomon Brothers, the brokerage firm, intends to spend nearly two years and more than $200 million cutting out floors, adding elevators, reinforcing steel girders, upgrading power supplies and making other improvements in its million square feet of space.

The work, which began last month at Seven World Trade Center, reflects both the adaptability of steel-framed towers and the extraordinary importance of fail-safe computer and telephone systems for the brokerage industry. According to many real estate experts, no company has ever made such extensive alterations to a new office building in Manhattan.

Much of the new electrical, air-conditioning and mechanical equipment will serve three double-height trading floors. To create the extra height, workers are removing most of three existing floors, using jackhammers to demolish concrete slabs and torches to remove steel decking and girders beneath the concrete.

After the girders are cut into sections small enough to fit into a construction elevator they will be sold as scrap for about 4 cents a pound.

In some office buildings, that alteration would be impossible, but Silverstein Properties tried to second-guess the needs of potential tenants when it designed Seven World Trade Center as a speculative project.

''We built in enough redundancy to allow entire portions of floors to be removed without affecting the building's structural integrity, on the assumption that someone might need double-height floors,'' said Larry Silverstein, president of the company. ''Sure enough, Salomon had that need.

''And there were many other ways that we designed as much adaptability as possible into the building because we knew that flexible layout is important to large space users.''

MORE than 375 tons of steel - requiring 12 miles of welding - will be installed to reinforce floors for Salomon's extra equipment.

No more than you. In fact, less so.I think it was NIST who were overly fixated on this girder.

It follows naturally that insulated materials become evenly heated. Nobody should argue with that.They supposed that the whole area heated to 600 deg evenly, and we took that to have happened in our analysis.

You bring a two-dimensional static analysis to the table with a one-dimensional argument, and complain their animation is "unrealistic". Hmmm.Steel will begin to sag over 600 which would render them to have lost just under half of their tensile strength. Looking at their animations their failure of column 79 is totally unrealistic

This is "deck-chairs" argument. If you have read what I have recently written you must surely acknowledge this.had they included the correct dimensions and elements would have been even more impossible.

To me the situations are equally difficult to explain. The first is: how did that floor plane resolve its external tension with its internal compression, where beams were sagging and putting their studs into shear? The second is: how did the floors pile up to push those bridging trusses sideways? ...Equally difficult.I would imagine that the main transfer truss systems would have to fail, but I cannot accept that the failure of one column (79) could possibly cause a building to fail in this way.

I don't think so, unless it offers a timeline with dynamic events happening at discrete locations, which it truly cannot.We recently did an analysis of their statements from 2008 re the issue which may be of interest

I know you do. But some things, though they obviously happened, cannot be described. Unforeseen events are built into the construction of all buildings. Misalignments, tolerances, reworking, material specifications, all introduce a range of possibilities. Unforeseen dynamic events (pipe runs, heavy equipment location, mass air movement) subtly alter trajectories. There is no certainty to be found here.I disagree that we would 'never know' what caused this failure.

See above.Given <snip> ASAP.

You hadn't read my previous post, perhaps, which went: "So, even if the beam next to C79 hadn't walked off its support, what sort of instance may cause it to do so? I will suggest an answer to this: the failure of the studs by sagging beam leverage. This could have been a failure elsewhere. The floor was already unstable, being restrained by its outsides. The exterior was in tension, the interior was under compression, wanting to walk up or down. The whole was elastic, like so many springs, and the shock loads caused by the sudden release of a fixing point would have been transmitted around it".I would enjoy an intellectually honest discussion of this issue without the logical fallacy. You say: "The first consequence was that column 79 buckled. The load it was supporting was everything above it". The first consequence of what?

See above.Thermal <snip> way.

But NIST actually DID account for near-free-fall acceleration, and I agree with it.Collapse time in no way accounts for ANY period of freefall acceleration occurring, which i presume, like NIST you do not dispute.

[...]. Not in my experience. The internal collapse buckling was so silent that you don't believe it occurred. The silent external collapse of the plane surfaces of the exterior we all witnessed.Buckling is neither silent, or in these circumstances, rapid

You make him sound like some dilettante when in fact he is the father of civil engineering. He is its Newton.as for eulers method, you should take a look at that again with regard to slenderness ratios etc, and please do not tell me that column 79 was slender because it is 47 storeys in height. I would rather not have a maths peeing contest with you, but if that's the way it is going, perhaps it would be better done on a different thread. I am happy to do that if you like.

Nope. WTC7 is obviously non-redundant in many respects. A truly redundant structure would be a three-dimensional mesh of tetrahedral struts. WTC7 is mainly a non-redundant structure of floor laminae with external wind-force bracing, with its internal columns standing on bridge trusses. That is highly non-redundant. You could hardly make it more so.Wrong.

Now there speaks a true engineer, eh. It's amazing what cherries may be picked when you go looking.''We built in enough redundancy to allow entire portions of floors to be removed without affecting the building's structural integrity, on the assumption that someone might need double-height floors,'' said Larry Silverstein

It moderates the idea that WTC7 was permanently bonded together in every way, doesn't it? See Boston below.''And there were many other ways that we designed as much adaptability as possible into the building because we knew that flexible layout is important to large space users.''

Bring it on.Maths fight!

A "proper" peer-journal would be AE9-11 Truth. This argument is peerless as far as engineers would be concerned, and that's not far.query as to whether you are going to get this work published in a proper peer-journal

Ain't that the truth.but making a convincing case that stands up to scrutiny by engineers would be something else.

But that's MY argument too. Think of that whole floor in a giant push-me, pull-you, squeezed by its periphery, and you're getting there.there's way more resistance to this girder moving any direction but down due to all the other factors yet to be considered.

See above.The corrugated deck <snip> can't occur.

I'm really not hearing a rational argument <snip> the credits all yours, I'm just offering to facilitate the process.

It runs perfectly for me. Those truther sites are full of bugs and viruses.The site has been running slower and slower for several days and at this point, is completely non functional.

I am not even responding to your BS, sorry. Say something that adds to the exchange and I will.Just an afterthought.

WTC7 was struck by pieces of WTC1, caught fire, and burnt for seven hours before it suddenly, and silently, collapsed.

What was the reasoning for wiring it up when there wasn't (obviously) an available plane?

Or did they wire it up thinking there was an available plane, then there wasn't one, and luckily WTC hit it, and started fires?

Knowing that there was no water, and with the firemen saying WTC7 was about to collapse, they let off these explosives anyway, so as to conceal their existence?

Knowing they could do anything, I suppose they could come up with water-cooled digital logic radio-controlled detonators, and water-cooled thermite explosive packs...

But weren't they taking a bit of a risk there? It's not like them to take risks, or even get things right in the first place.

Couldn't they find a cheaper way of shredding documents and destroying hard-drives? (That's enough - Ed.)

Yes, I would go along with that, there's a bit more to it obviously, but all in all, a pretty good summary. Thanks.

Abandoning the engineering issues for the standard 'tell me a story so I can make fun of it..!' evade. The quickening is complete. There can be only one.Just an afterthought.

WTC7 was struck by pieces of WTC1, caught fire, and burnt for seven hours before it suddenly, and silently, collapsed.

What was the reasoning for wiring it up when there wasn't (obviously) an available plane?

Or did they wire it up thinking there was an available plane, then there wasn't one, and luckily WTC hit it, and started fires?

Knowing that there was no water, and with the firemen saying WTC7 was about to collapse, they let off these explosives anyway, so as to conceal their existence?

Knowing they could do anything, I suppose they could come up with water-cooled digital logic radio-controlled detonators, and water-cooled thermite explosive packs...

But weren't they taking a bit of a risk there? It's not like them to take risks, or even get things right in the first place.

Couldn't they find a cheaper way of shredding documents and destroying hard-drives? (That's enough - Ed.)

I have nothing to challenge or question your claims at the moment, I would just ask why what Jazzy said couldn't be true. I would also ask just as a side note, do you have an alternative as to what happened? Or are you just presenting a critique?

Found some:

Full image:

Hard to say which floor that would be from.

Also there's some here, in the upper right

Look, sunshine, so far I have made these statements/asked these questions which you haven't yet had the decency either to acknowledge or properly reply to:I am not even responding to your BS, sorry. Say something that adds to the exchange and I will.

See above.Abandoning the engineering issues for the standard 'tell me a story so I can make fun of it..!' evade. The quickening is complete. There can be only one.

Ignoring the whole of the rest of the building, and in particular the rest of the floor impinging upon column 79, is deeply and truly "an incompetent incoherent way to deal with the issue".He is saying that I am fixating on one single column, which is EXACTLY what NIST did. In examining their explanation, if I strayed very far from the initialing event that would be an incompetent incoherent way to deal with the issue.

Again I ask - what "exchange"? Everything above in blue has taken no part of any "exchange".Jazzy seems more interested in some childish point scoring exchange

In a pig's ear.rather than a serious discussion that is focused on an honest search for the truth about what happened to this building. I recognize that this site seems to be a place that facilitates such an exchange and I welcome that.

No. I am long on REASON. It's you that is substituting exchange with rhetoric. The "facts" are already established. The interpretation of these "facts" is the issue.Jazzy is long on rhetoric and short on facts.

My working to which non-existent exchange do you mean?He needs to show his working

I think you're right because neither of us knows what you're talking about.I don't think he will, and I will respond if/when he does.

There are NO shear studs on Column 79. Just two fixing bolts, top and bottom.Hope this has worked, I could find you a link to the whole set if you like, they were released under a FOIA request.

There are NO shear studs on Column 79. Just two fixing bolts, top and bottom.

Now that's a critical error/omission!

Or perhaps we need the rest of the set to make sense of this.

I must be. I can't see the relevance. There's no shear resistance apart from the bolts shown, and the concrete floor would have expanded with the steel. The concrete shear studs only serve to keep the support trays attached, so that the floor would tend to move as a single piece.Are you confusing shear studs (studs on top of a beam that embed in the concrete) with bolted shear plates? Because I don't think that shear studs would show on that diagram, as it's just a connection diagram.

Now that's a critical error/omission! lol. You clearly do not understand what a shear stud is, let alone what function it performs. Also, look at the welding that is called out at the top of the plate.There are NO shear studs on Column 79. Just two fixing bolts, top and bottom.

Now that's a critical error/omission!

Or perhaps we need the rest of the set to make sense of this.

I can kind of see where you are getting confused with this, and rather than confusing you more, is there a facility on here to actually talk real time? I think I could maybe clear up some of the misconceptions that you have about the nature of this connection and the elements around it. Would take too long in text. Maybe it is not made as clear as it could be in the videos. The plate in question isn't a backing plate, it is plate 'pf' and is underneath the girder at column 79. It isn't shown in the above illustration that you use. This is NIST referring to the plate:-I must be. I can't see the relevance. There's no shear resistance apart from the bolts shown, and the concrete floor would have expanded with the steel. The concrete shear studs only serve to keep the support trays attached, so that the floor would tend to move as a single piece.

The floor, heated from beneath, would sag initially merely due to the temperature gradient across it. Later on it would tend to straighten, were it not for the fact it was halving its tensile strength, and creeping. When tied together through the columns to all the other floor elements its "center" would move in the direction of any opening in the floor. It would also be trying to squirm (up or down) due to being under compression by the cold, non-expanded exterior periphery.

A hot loaded column, as Column 79 certainly was, would have had plenty of time over seven hours to sag vertically down (allowing everything it supported to do mostly the same) and distort sideways to follow this movement, being at a temperature 125 deg C above its creep transition point.

Being out-of-line in such a manner would have made it extremely prone to buckling collapse: Euler's Law refers to classically vertical/horizontal structures only. Two consecutive collapsed floors would put it past critical even if it were straight.

You have to account for nine or ten inches too much of compressed steel/concrete across the floor plane, with the periphery in tension. I think that if C79's centerline were to be five inches out-of-vertical, then floor collapse and column buckling might well be a simultaneous event.

This could easily happen if the fire moved through the building. Consider one side of the floor already up to temperature, sagging and pulling. Then if the fire crossed to the other side it could heat the floor, causing it to expand before it began to sag. That would create a powerful sideways push on the central columns. This process was observed in the tower fires, where first the floors expanded, pushing the external columns outwards, then they crept and sagged, pulling the same columns inwards.

You're right, Gerrycan, whether a backing plate is eleven or twelve inches across has little relevance to the general state of this WTC7 floor. Or to anything...

It's still a little confusing though as the actual WTC7 blueprints sometimes refer to those girders as beams (As in Drawing 9114, "Beam to Column Connections")[/q

Yes there was actually quite substantial mesh above the girder (element spanning column 79-44, just to be clear lol) and you are also correct about the beam to the west that gives the girder lateral support. Also it is worth remembering that even if the floor beams to the east and the girder itself failed, this does not leave the column entirely unbraced. There is also additional bracing in a sort of diamond shape around the column connection that isn't shown on these drawings to provide support for piping. I reckon that the drawings that NIST need to be releasing are fieldwork drawings (FW prefix). Maybe these would show additional work that would be done to the girder also, but I can't be sure as they claim not to have them, (which I do not believe for a minute).LMAO

Girders tend to hold the beams, beams tend to hold the joists, joist hold the subfloor/decking/floor. If you really want to get technical there's perlins and subperlins as well as girt beams and a whole slew of other terms. But for the purposes of this conversation I think we can all agree that a girder is in support of the beams that held the trusses which held the floors.

Sheer studs are what rise vertically off the top of the beam and embed in the concrete, the corrugated pans are cut out to accommodate them and often the pans are welded down to the beams at these cut outs. Also if you look at the drawing offered for our consideration you can see there is a change in direction of the floor pans and beam layout that would have facilitated further welding of the pans directly on top of the girder in question. There would also be an accompanying change in direction of any internal mesh or rebar, guys tend to overlap that stuff and tie wire it into place. Makes that area of floor stronger than the typical floor section.

there's another sticky little issue with the walked off its seat hypothesis, anyone notice that other beam coming in at a rather high angle to the girder on the back side of where the alleged push originated from ? Makes it kinda hard for that beam to walk anywhere if you ask me.

Now that's a critical error/omission! lol. You clearly do not understand what a shear stud is, let alone what function it performs. Also, look at the welding that is called out at the top of the plate.

Yes there was actually quite substantial mesh above the girder (element spanning column 79-44, just to be clear lol) and you are also correct about the beam to the west that gives the girder lateral support. Also it is worth remembering that even if the floor beams to the east and the girder itself failed, this does not leave the column entirely unbraced. There is also additional bracing in a sort of diamond shape around the column connection that isn't shown on these drawings to provide support for piping. I reckon that the drawings that NIST need to be releasing are fieldwork drawings (FW prefix). Maybe these would show additional work that would be done to the girder also, but I can't be sure as they claim not to have them, (which I do not believe for a minute).

You may well be reading carefully what I have written (I can hardly believe this), but what I have written certainly isn't sinking in.I can kind of see where you are getting confused with this