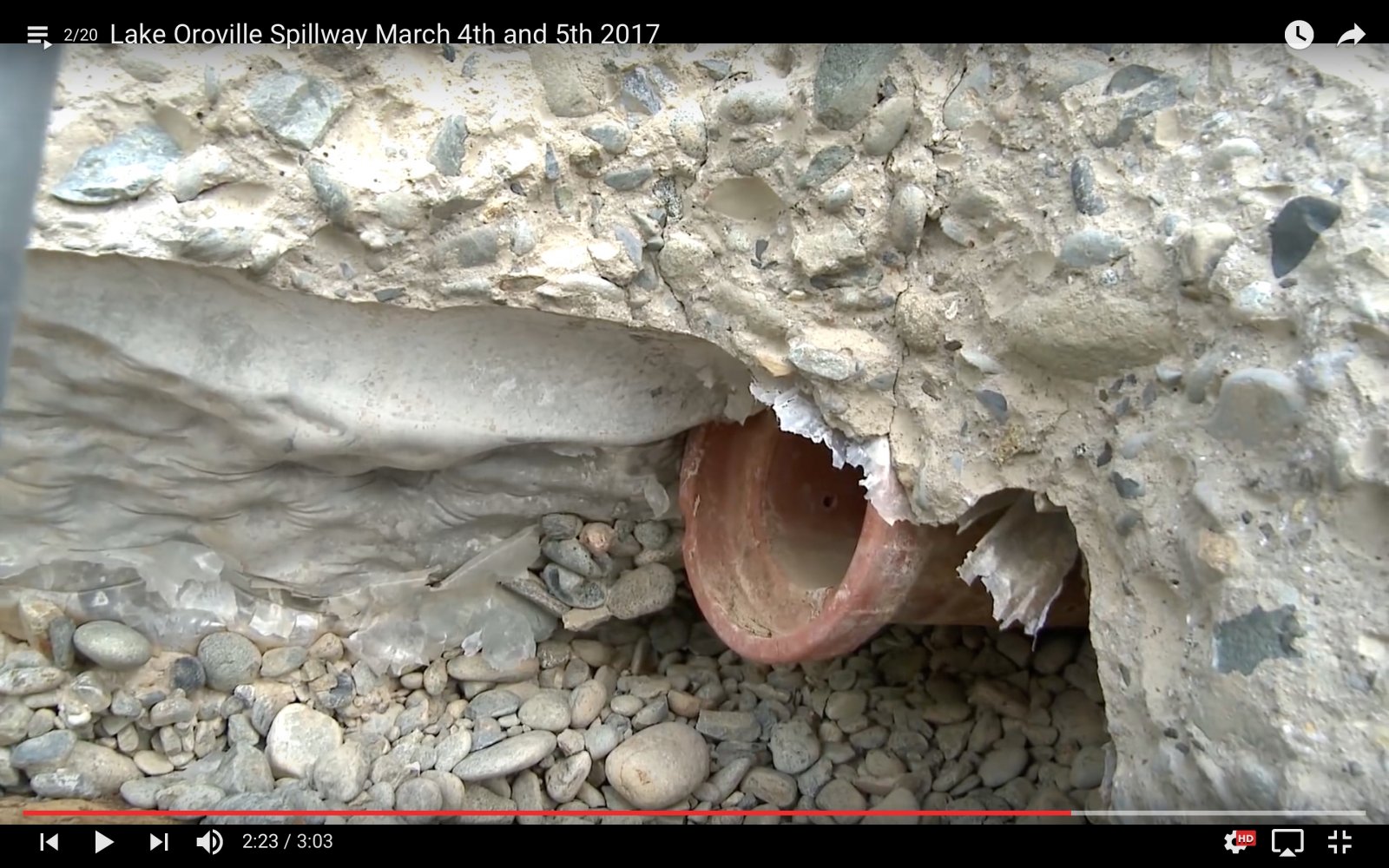

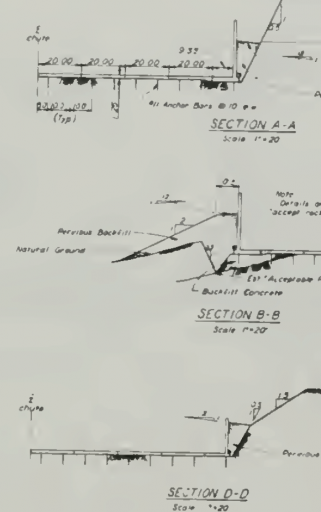

An extensive system of sub-drainage and collector pipes (over 21,000 feet) exist beneath the approach slab, the ogee weir, the chute slab and stilling basin and behind the chute walls.

The pipes range in diameter from 3 to 12 inches. Pipe material types include solid and perforated PVC, solid and perforated vitrified clay pipe, solid asbestos cement pipe and perforated CMP. 1.3

Objectives: The overall objective of this contract is to thoroughly document the current condition of the sub-surface drains and collector pipes of the spillway structure. 1.4

Scope: Work generally consists of visual inspecting the drainage pipe (both vertical and horizontal) with remote-operated camera equipment and producing a detailed formal report to thoroughly document the condition of these features. To enable visual inspection of the vertical chute slab foundation drains (18 total), mechanical cleaning (brushing and flushing with water) will be required for these pipes. Deliverables from this work will include DVD(s) of the inspection footage and a report that summarizes the procedures and findings of all inspections and includes individual inspection logs that summarizes the condition each pipe segment and documents the location of any significant observation.

The Contractor shall perform these services as noted in this PWS. All work shall be conducted in accordance with current professional standards, Corps of Engineers policies, regulations, and procedures. The Contractor is responsible for supplying all equipment, supplies, materials and personnel necessary for the completion of this work. 1.5 Scope Period of Performance: The period of performance for the PWS shall be