Iron rich microspheres can be made in various ways. In this thread I investigate some of them, and try to make some microspheres of my own.

Burning Methods (external ignition heat from flames)

- Burning Paint Chips #1. https://www.metabunk.org/posts/218647/

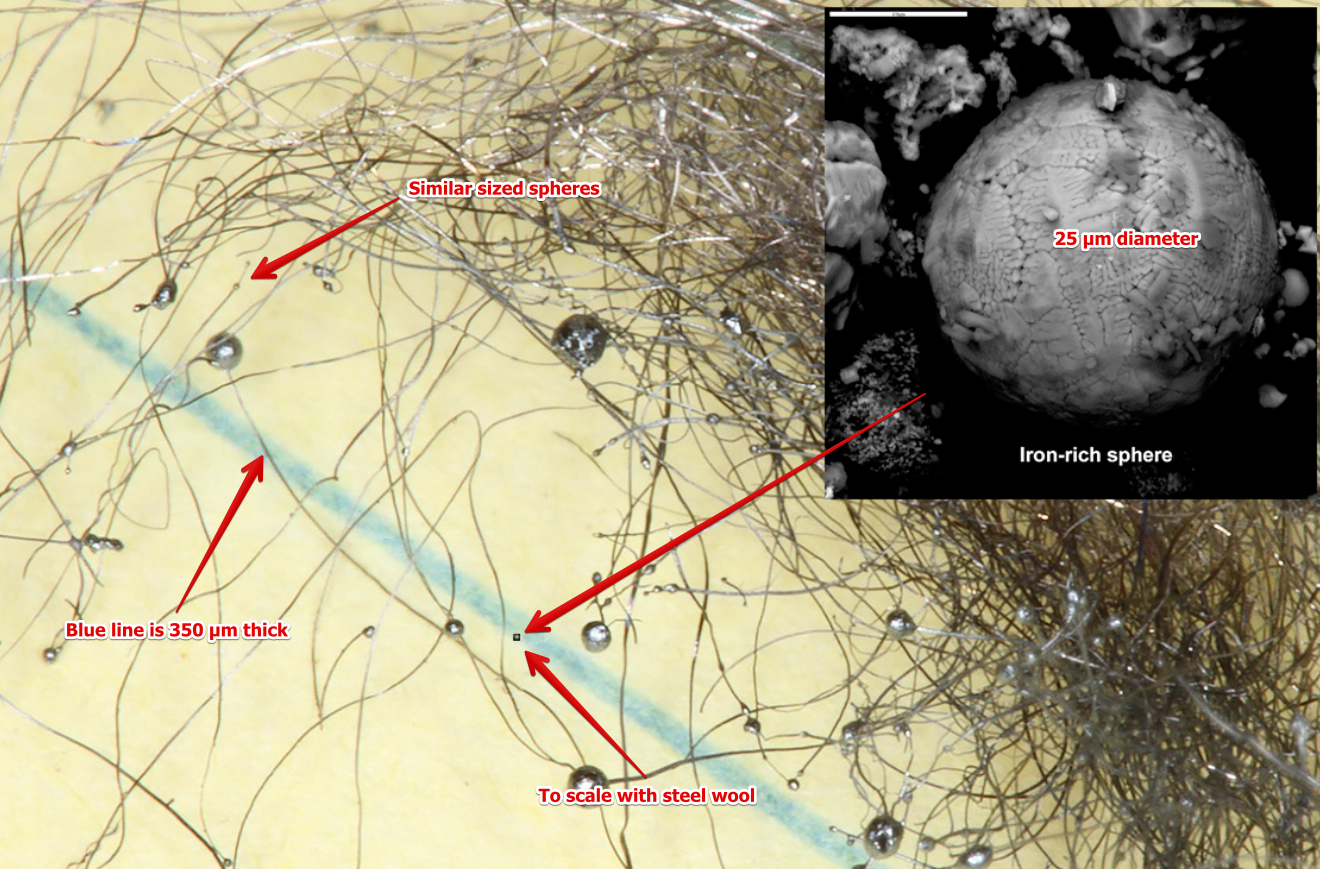

- Steel Wool #1: https://www.metabunk.org/posts/219558/

- Iron Filings #1: https://www.metabunk.org/posts/219574/

- Toner: https://www.metabunk.org/posts/219612/

- Steel Wool #2: https://www.metabunk.org/posts/219648/

- Burning Paint Chips #2: https://www.metabunk.org/posts/219649/

- Iron Powder 320 Mesh: https://www.metabunk.org/posts/225668/

- Iron Filings 50 Mesh: https://www.metabunk.org/posts/225672/

- *Pyrophoric iron: https://www.metabunk.org/posts/219592/

- Steel Wool #3 (physics investigation): https://www.metabunk.org/threads/what-happens-when-you-burn-steel-wool.10002/

Sparking methods (impact causing both scraping and ignition heat)

- Steel on steel impact. https://www.metabunk.org/posts/219454/

- Angle Grinder: https://www.metabunk.org/posts/219490/

- Bic Lighter: https://www.metabunk.org/posts/219555/

- Flint Striker: https://www.metabunk.org/posts/219584/

- Rust on aluminum impact: https://www.metabunk.org/posts/219689/

- 1600's Flint: https://www.metabunk.org/posts/219589/

Melting Methods (External Energy/Heat Melting steel/iron)

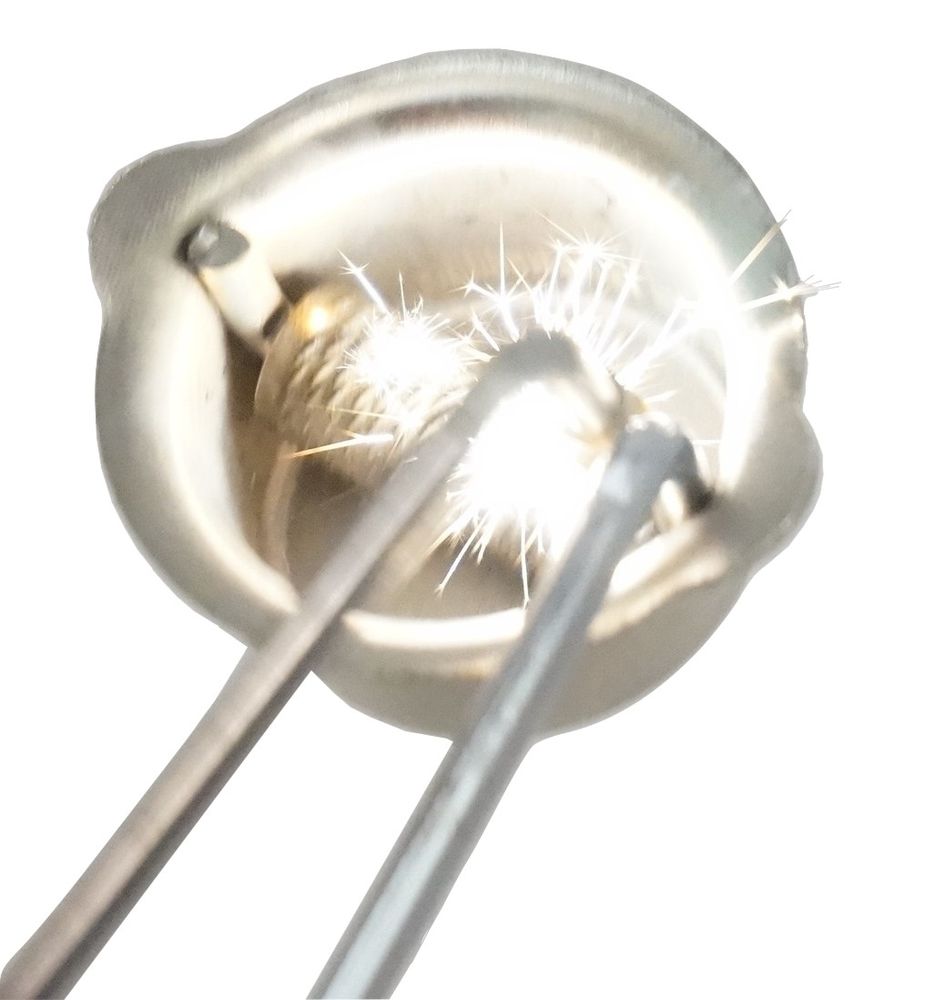

- Arc Welding #1 (Magnet capture): https://www.metabunk.org/posts/219499/

- Arc Welding #2 (Water capture): https://www.metabunk.org/posts/219888/

- *Oxy cutting

- *Thermal lance cutting

Chemical Reaction Method (chemical reaction with molten or vapor iron as a product)

- Thermite (Al + Fe2O3): https://www.metabunk.org/posts/219775/

* = Methods I've not personally tried

Last edited: