Most Reclamation structures have been designed with joint details that protect the slab foundation, but this cannot be said for all spillways. There are concrete slab structures on earth foundations that do not have appropriate (waterstop) protection. When water penetrates beneath the slab, it can lead to erosion and potentially structural collapse. As structures age, there also are uncertainties regarding the condition of waterstops and their ability to inhibit water from reaching the foundation through an open-offset joint or crack. If it is a crack, there is no protection and so they perhaps are more critical.

(snip)

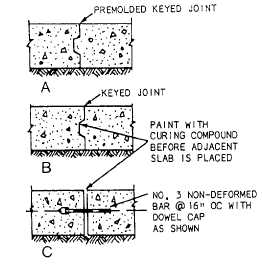

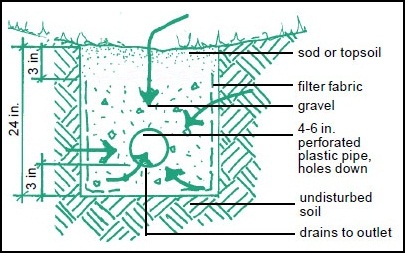

In reinforced concrete-lined chutes, the stability of the slab depends on the overall concrete design, including: joint and waterstop details; reinforcement; anchorage; and a functioning, filtered underdrain system. Usually, drainage under the slab is provided to prevent the build up of uplift pressure and subsequent instability due to seepage and natural foundation groundwater conditions. Typically, damage resulting from hydrodynamic uplift on slabs (jacking) begins at the joints, where offsets or spalling has occurred. Spillway flows over these offsets can introduce water into the foundation, which can lead to structural damage as a result of either uplift or erosion of the foundation material.

If this problem persists, there can be complete failure and removal of chute slabs. Structural collapse due to undermining of the chute slabs has been a difficult problem to evaluate due to lack of applicable data or analyses. This problem is generally more of a concern for structures where the chute and underdrain systems may be in poor condition due to aging or improper design. This problem is especially critical for chutes that are founded on soil because joint/crack flow can lead to erosion and undermining of the chute foundation and structural collapse of a chute slab.