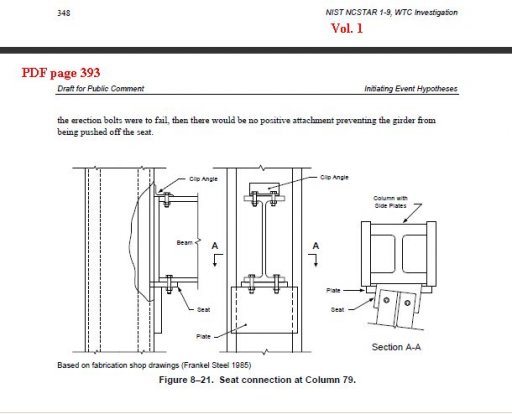

Now that's a critical error/omission! lol. You clearly do not understand what a shear stud is, let alone what function it performs. Also, look at the welding that is called out at the top of the plate.

Now that's a critical error/omission!

Isn't it just.

You clearly do not understand what a shear stud is, let alone what function it performs

Good. Hasn't taken you long to suss out a lack of knowledge masquerading as the opposite. You might like to check Jazzy's 'theory' about the friction welding caused by the threaded floors during the towers' collapses, which in turn transferred enough heat to the bottom of the pile to maintain it at the temps observed for weeks after! It's quite, er, 'remarkable'.

More seriously, though, G - excellent work! I'd agree with Boston on the tidying up and presenting for review. It looks like a slam-dunk to me. I can't find any issues in the detail; so all that remains is really a few drafts to distil the message to its purest possible configuration. It's not far off as it is, but never hurts to finesse to the max.

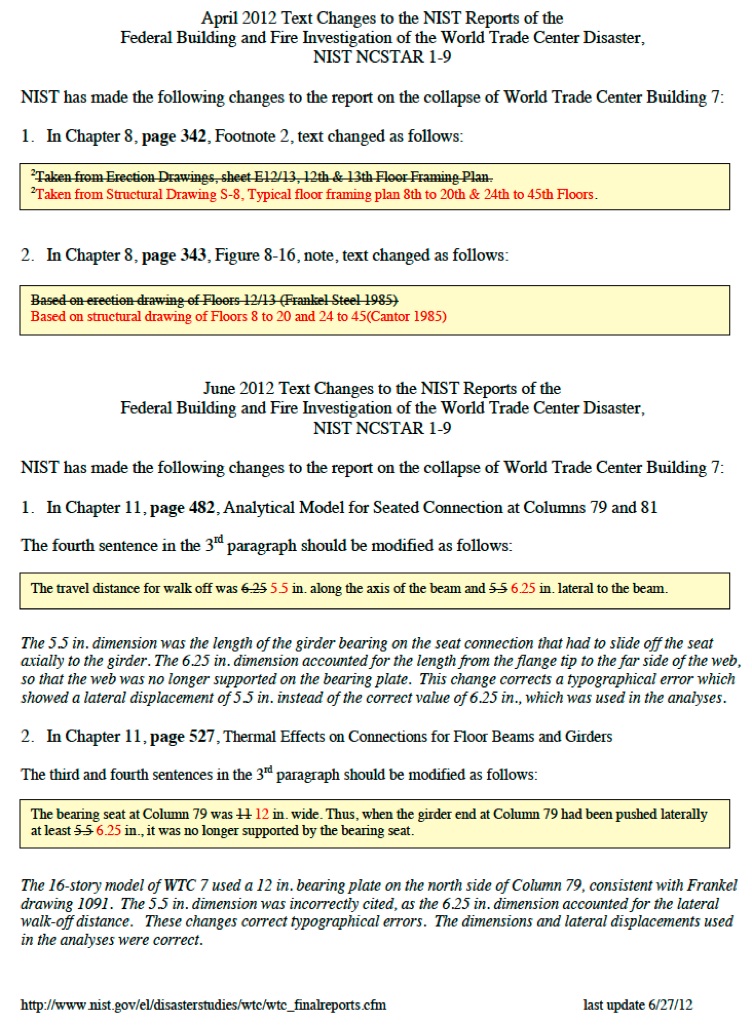

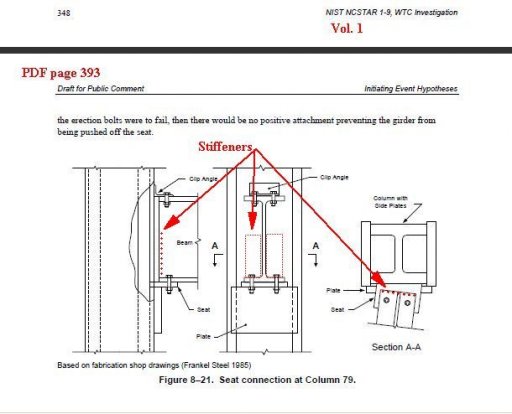

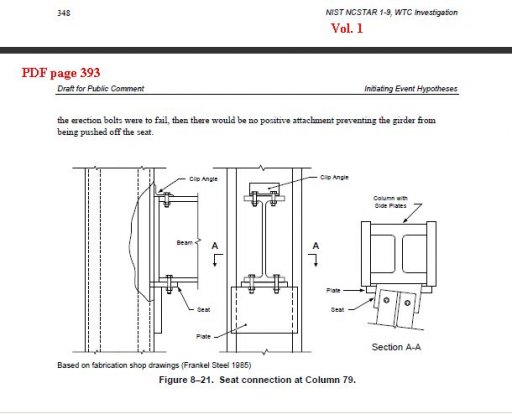

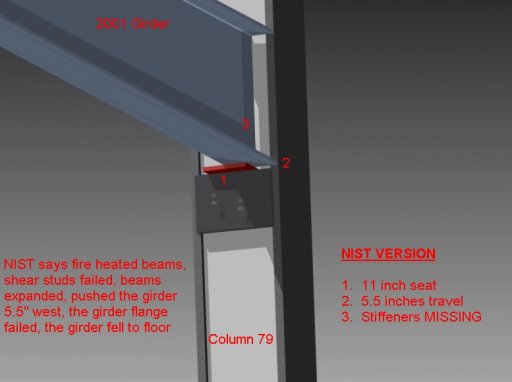

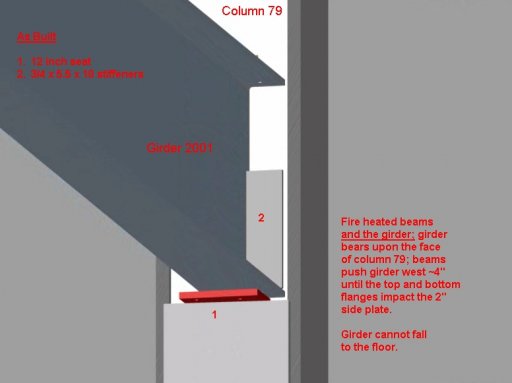

Q: Did you make a request to NIST to issue the erratum sheet after finding the connection detail (12 vs 11) error? (or other?). It's quite astonishing they could make such a basic 'mistake'; add to that the second 'erratum' which just happens to relate to the first directly - as it's the central plank of their whole 'cause of collapse' scenario, can they just change the numbers every time someone points to an obvious error? At the very least this is gross incompetence; but how can you 'mis'read the drawings in your possession and to which you refer for your hypothesis without being guilty of something more than incompetence? Now we know why they didn't want the drawings in the public domain, eh?

More generally, thinking about it, it would be critical in your presentation to make the point on the temps selected by NIST (ie up to 600C) which again benefits their hypothesis of expansion (but no sagging - which would further kill the idea) to the maximum. And juxtaposing all that information with the changes NIST have recently made re: 11 inches to 12 (for the seat) + 5.5 inches to 6.25 (for the expansion), and the claim of 'typo'/transposition'! I realise you've already indicated such, but think it's worth thinking really hard about exactly how that gets laid out on the page for maximum simplicity/elegance. Obviously, the 'new' 6.25 inch expansion figure is requiring temps beyond which further lateral expansion would be an issue, ie. when sagging comes into play. Also, given that office contents generally burn for a max of 30 mins before moving on, and that NIST themselves claimed in the case of WTC7 that this figure was approx 15 mins - then maybe something along the lines of a temp/time/expansion/sag graph of sorts? Given that the fire-proofing in 7 was intact, from plasterboard to sfrm - worth a mention maybe?

Just a few thoughts - but again, excellent - well done G!

Cheers

ps regarding the shear studs themselves - what are NIST suggesting in relation to those? That the expanding girder w/studs cracked the floor slab or they were sheared? Or do they just avoid it?