NCSTAR 1-A, page 21:

It is like a joke... They are guessing and in guessing they come up with a political science based conclusion designed to protect those in power... it is as simple as that.

They fully acknowledge that the temperatures are well below the temperatures considered in current practice for determining

fire resistance ratings associated with significant loss of steel strength

But it bothers them not one bit. If it is me that is wrong tell me in plain words how and why I am wrong.

It is like a joke... They are guessing and in guessing they come up with a political science based conclusion designed to protect those in power... it is as simple as that.

They fully acknowledge that the temperatures are well below the temperatures considered in current practice for determining

fire resistance ratings associated with significant loss of steel strength

But it bothers them not one bit. If it is me that is wrong tell me in plain words how and why I am wrong.

Content from external source:

As the fires progressed, some of the structural steel began to heat. According to the generally accepted test standard, ASTM E-119, one of the criteria for establishing the fire resistance rating for a steel column or floor beam is derived from the time at which, during a standard fire exposure, the average column

temperature exceeds 538 °C (1000 °F) or the average floor beam temperature exceeds 593 °C (1100 °F).

These are temperatures at which there is significant loss of steel strength and stiffness. Due to the

effectiveness of the SFRM, the highest column temperatures in WTC 7 only reached an estimated 300 °C

(570 °F), and only on the east side of the building did the floor beams reach or exceed about 600 °C

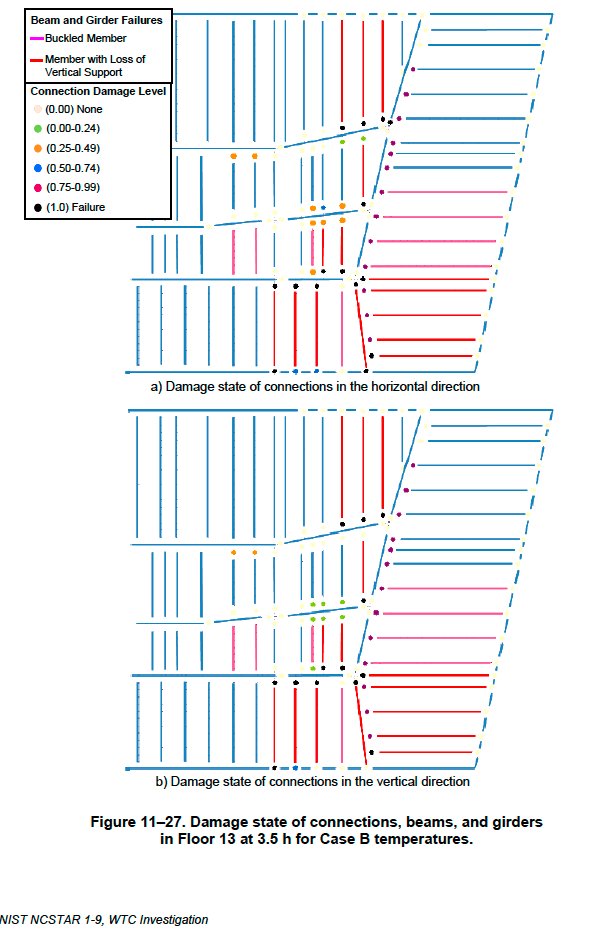

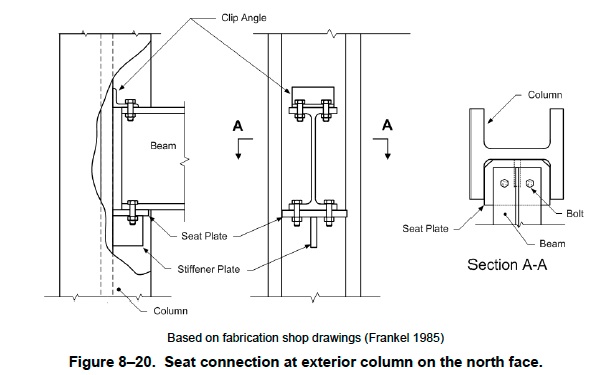

(1100 °F). The heat from these uncontrolled fires caused thermal expansion of the steel beams on the

lower floors of the east side of WTC 7, primarily at or below 400 ºC (750 ºF), damaging the floor framing

on multiple floors.

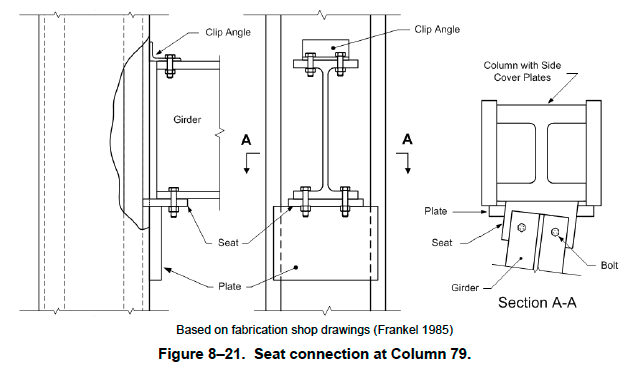

The initiating local failure that began the probable WTC 7 collapse sequence was the buckling of

Column 79. This buckling arose from a process that occurred at temperatures at or below approximately

400 °C (750 °F), which are well below the temperatures considered in current practice for determining

fire resistance ratings associated with significant loss of steel strength. When steel (or any other metal) is

heated, it expands. If thermal expansion in steel beams is resisted by columns or other steel members,

forces develop in the structural members that can result in buckling of beams or failures of connections.

Last edited by a moderator: