One of the suppliers of sustainable biofuels in the

Japan Airlines test flight earlier this year,

Sustainable Oils, has completed an analysis of the carbon lifecycle emissions from using jet fuel derived from its chosen plant, camelina. They have found that

the use of camelina-derived biojet would reduce emissions by 84% compared to traditional fossil fuel Jet A-1.

This doesn't mean that the carbon emissions coming out of the back of an aircraft engine are less – they will be around the same whether the fuel comes from biomass or fossil fuel. The difference comes when you consider that the biofuel feedstock requires carbon dioxide to grow – thus absorbing some of the CO2 that is emitted by the use of the fuel in flight. Fossil fuels used by cars, trucks, trains and planes are releasing carbon dioxide that has not been in the atmosphere for millions of years.

Put simply: if you look at a total lifecycle of the fuel, when a jet burns one tonne of today's fuel, it releases an additional 3.15 tonnes of carbon dioxide into the atmosphere that were not there already – they had been trapped underground. In the next few years, when a jet burns one tonne of fuel made from camelina, only around half a tonne of extra carbon dioxide will be released – an 84% reduction. The rest of the carbon dioxide released will have been absorbed as the camelina plant was grown.

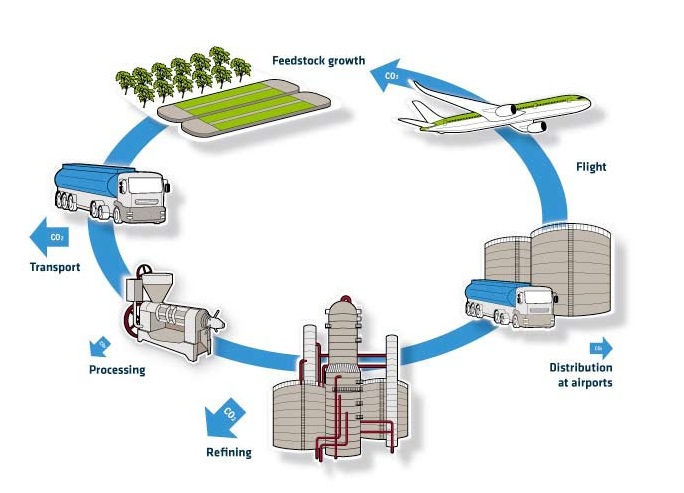

The reason why the emissions are not 100% reduced is that there is inefficiency in the supply chain – carbon released during processing, transport, refining and growing the biofuel. This could also become more efficient over time as well.

This measurement signifiantly changes the way we will have to look at the total emissions of the industry and it puts carbon neutral growth firmly within our reach. And there are early indications that a lifecycle analysis of the other feedstocks such as algae and jatropha will have similar lifecycle emissions footprints.