http://911research.wtc7.net/talks/wtc/videos.html

http://tinyurl.com/7drxn

WTC collapses due to controlled demolition

Steven E. Jones

Professor of Physics/BYU

I believe WTC collapses to be due to controlled demolition are:

1. My own analysis of the "pancaking" floors model (the FEMA/NIST model) combined with Conservation of Momentum considerations gives a much longer time for the fall (over 10 seconds) than that which was actually observed for WTC-7 (about 6.3 seconds, just over the free-fall time of 6.0 seconds). I find no evidence in their reports that government researchers (FEMA, NIST, 9-11 Commission) included Conservation of Momentum in their analyses.

2. The fact that WTC-7 fell down symmetrically, onto its own footprint very neatly, even though fires were just observed on one side of the building. A symmetrical collapse, as observed, requires the simultaneous "pulling" of support beams. By my count, there were 24 core columns and 57 perimeter columns in WTC-7. Heat transport considerations for steel beams heated by fire suggest that failure of even a few columns at the same time is very small. Adding in the Second Law of Thermodynamics ("law of increasing entropy") leads to the conclusion that the likelihood of near-symmetrical collapse of the building due to fires (the "government" theory) -- requiring as it does near-simultaneous failure of many support columns -- is infinitesimal. Yet near-symmetrical collapse of WTC-7 was observed. (If you still haven't gone to the links above to see the actual collapse for yourself, please go there now.)

Note that the 9-11 Commission report does not even deal with the collapse of WTC-7. This is a striking omission of highly relevant data.

3.Squibs (horizontal puffs of smoke and debris) are observed emerging from WTC-7, in regular sequence, just as the building starts to collapse. (SEE:

http://tinyurl.com/7drxn ) Yet the floors have not moved relative to one another yet, as one can verify from the videos, so air-expulsion due to collapsing floors is excluded. I have personally examined many building demolitions based on on-line videos, and the presence of such squibs firing in rapid sequence as observed is prima facie evidence for the use of pre-positioned explosives inside the building.

4. The pulverization of concrete to powder and the horizontal ejection of steel beams for hundreds of yards, observed clearly in the collapses of the WTC towers, requires much more energy than is available from gravitational potential energy alone. Explosives will give the observed features. Other scientists have provided quantitative analysis of the observed pulverizations, and I can provide references if you wish. Here we are appealing to the violation of Conservation of Energy inherent in the "official" pancaking-floors theory-- a horrendous violation, forbidden by principles of Physics. (What is going on for the FEMA/NIST researchers to make such striking errors/omissions?)

5. I conducted simple experiments on the "pancaking" theory, by dropping cement blocks from approximately 12 feet onto other cement blocks. (The floors in the WTC buildings were about 12 feet apart.) We are supposed to believe, from the pancaking theory, that a concrete floor dropping 12 feet onto another concrete floor will result in PULVERIZED concrete observed during the Towers' collapses! Nonsense! My own experiments, and I welcome you to try this yourself, is that only chips/large chunks of cement flaked off the blocks -- no mass pulverization to approx. 100-micron powder as observed. Explosives, however, can indeed convert concrete to dust --mostly, along with some large chunks-- as observed in the destruction of the Twin Towers on 9-11-01.

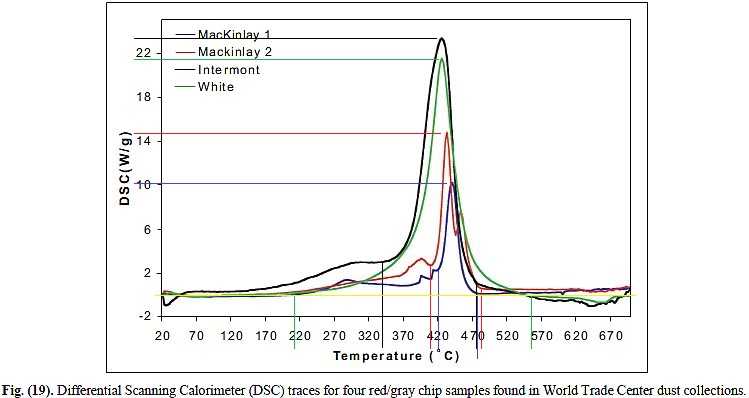

6. The observations of molten metal (I did not say molten steel!) in the basements of all three buildings, WTC 1, 2 and 7 is consistent with the use of the extremely high-temperature thermite reaction: iron oxide + aluminum powder --> Al2O3 + molten iron. Falling buildings are not observed to generate melting of large quantities of molten metal -- this requires a concentrated heat source such as explosives. Even the government reports admit that the fires were insufficient to melt steel beams (they argue for heating and warping then failure of these beams) -- but these reports do not mention the observed molten metal in the basements of WTC1, 2 and 7. Again we have a glaring omission of critical data in the FEMA, NIST and 9-11 Commission reports.

7. I understand that models of the steel-frame WTC buildings at Underwriters Laboratories subjected to intense fires did NOT collapse. And no steel-frame buildings before or after 9/11/2001 have collapsed due to fire. Thus, the "official" fire-pancaking model fails the scientific test of REPRODUCIBILITY. (Earthquake- caused collapses have occured, but there were no major earthquakes in NYC on that day. And buildings which have collapsed due to earthquakes collapse asymmetrically, as expected -- not like the nearly straight-down collapse of WTC 7 to a small rubble pile!)

8. Explosions -- multiple loud explosions in rapid sequence -- were heard and reported by numerous observers in (and near) the WTC buildings, consistent with explosive demolition. Some of the firemen who reported explosions barely escaped with their lives.

Essentially none of these science-based considerations is mentioned in the Popular Mechanics article on this subject, authored by B. Chertoff (a cousin of M. Chertoff who heads the Homeland Security Dept.) (Squibs are mentioned briefly, but the brief PM analysis does not fit the observed facts.)

I have performed other analyses regarding the WTC collapses on 9-11-01 which may be of interest --let me know if you're interested. The matter is highly interesting to me as a physicist -- and as a citizen of the United States. I conclude that the evidence for pre-positioned explosives in WTC 7 (also in towers 1 and 2) is truly compelling.

Steven E. Jones

Professor of Physics/BYU

This article was posted on 9.16.05