You assume that the only thing heated and deformed in the fires was that single girder and the beams framing into it from the east, right?

No.

The building had been on fire for hours on several floors surrounding that area. Girders and beams would have expanded and/or sagged on different floors at different times, pushing and pulling the columns around. There were more connection failures elsewhere.

Bending and sagging floor beams and girders could NOT push the columns around because the columns were surrounded by cement slabs. There would be movement due to thermal expansion but

everything would expand together.

It is a self evident axiom of physics that things cannot expand inward, only outward. So Hulsey's central point of no expansion is correct.

Column 79 is in the center of the pale green which means that it was displaced about 1-3/4 inches from the center of the building.

Column 44 is in the yellow area and closer to the pale green than the pale orange so it was displaced abut 1-1/4 inches from the central point.

That would put the area between columns 79 and 44 in compression.

And it's the thermal expansion between columns 79 and 44 that we are concerned with.

It is my understanding that concrete expands at 85% the rate of structural steel so the differential is inconsequential.

Here is the Math with graphics.

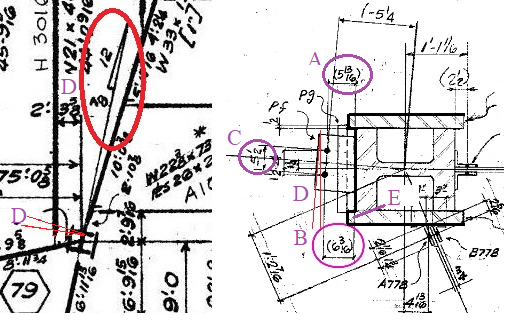

A2001 - east end of flange to column face (flange)

center line of bolt holes at center line of seat (and girder) to column face (flange)

A + B

5-13/16 + 6-3/16 = 12 divided by 2 = 6 inches

center line of bolt holes to end of girder 4-1/4 inches

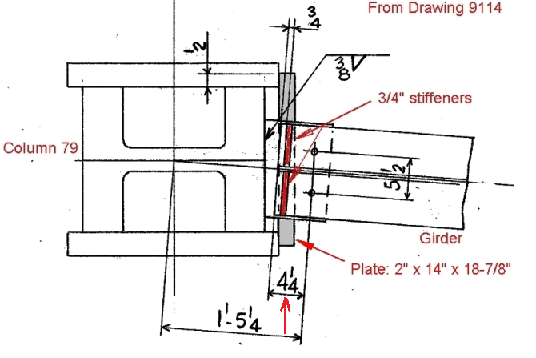

center line of A2001 girder to face of column 79 - 1-3/4 inches

girder flange 11-1/2 inches wide divided by 2 = 5-3/4 inches

east end of girder flange 5-3/4 inches from girder center line

angle is 7/8:12 or 7/16 in 6 inches so:

1-3/4 – 7/16 = 1-5/16

east end of girder flange just over 1-5/16 inches from column face

A2001 girder 45 feet

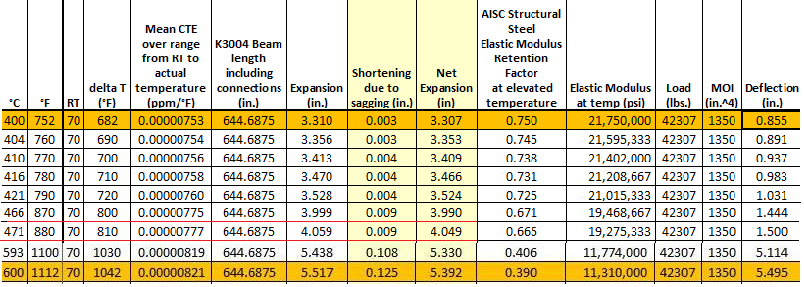

K3004 floor beam 53.57 feet – expands 3.3 inches at 400 °C

45 divided by 53.75 = .837

45 is 83.7% of 53.75

3.3 x .837 = 2.76 or 2-3/4 inches

A2001 expands 2-3/4 inches at 400 °C