Representative Press

Member

[Thread split from https://www.metabunk.org/threads/cr...ssions-in-wtc7-report-uncovered.2332/page-12]

yes? So you agree that fires caused the collapse right? yes or no?

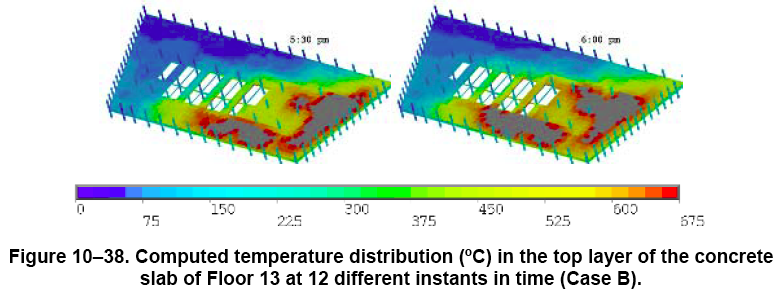

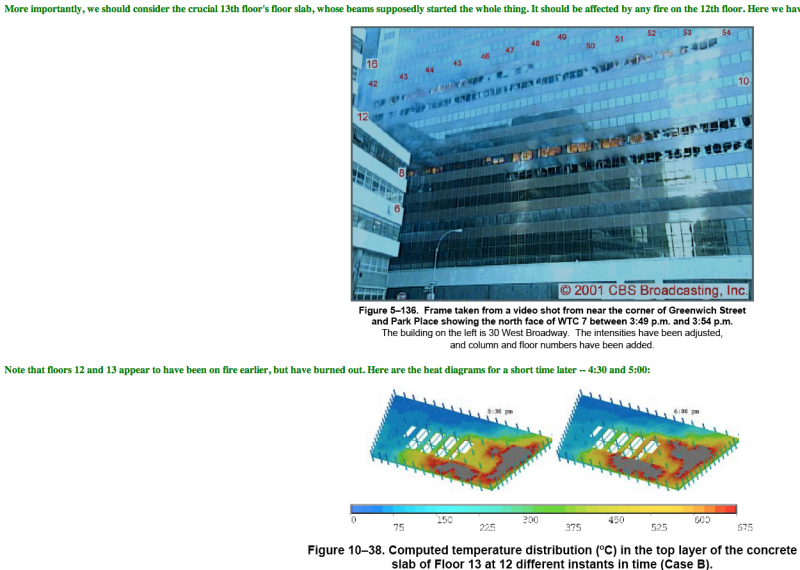

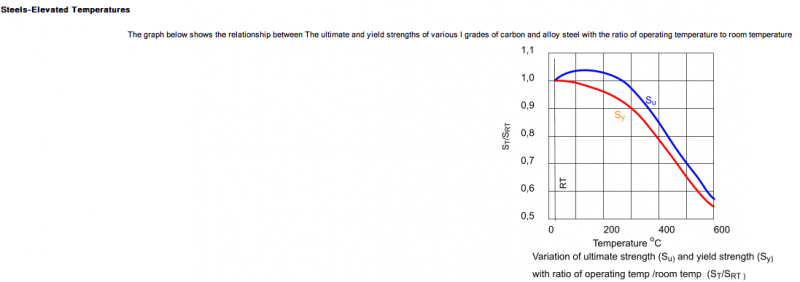

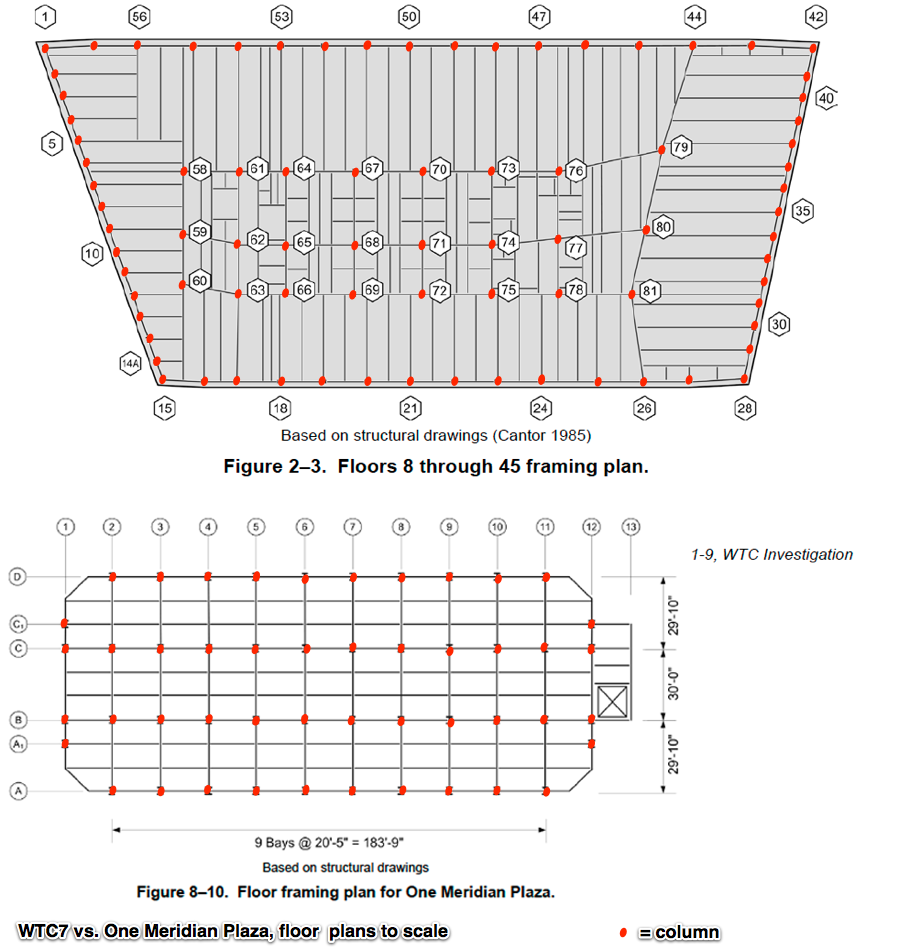

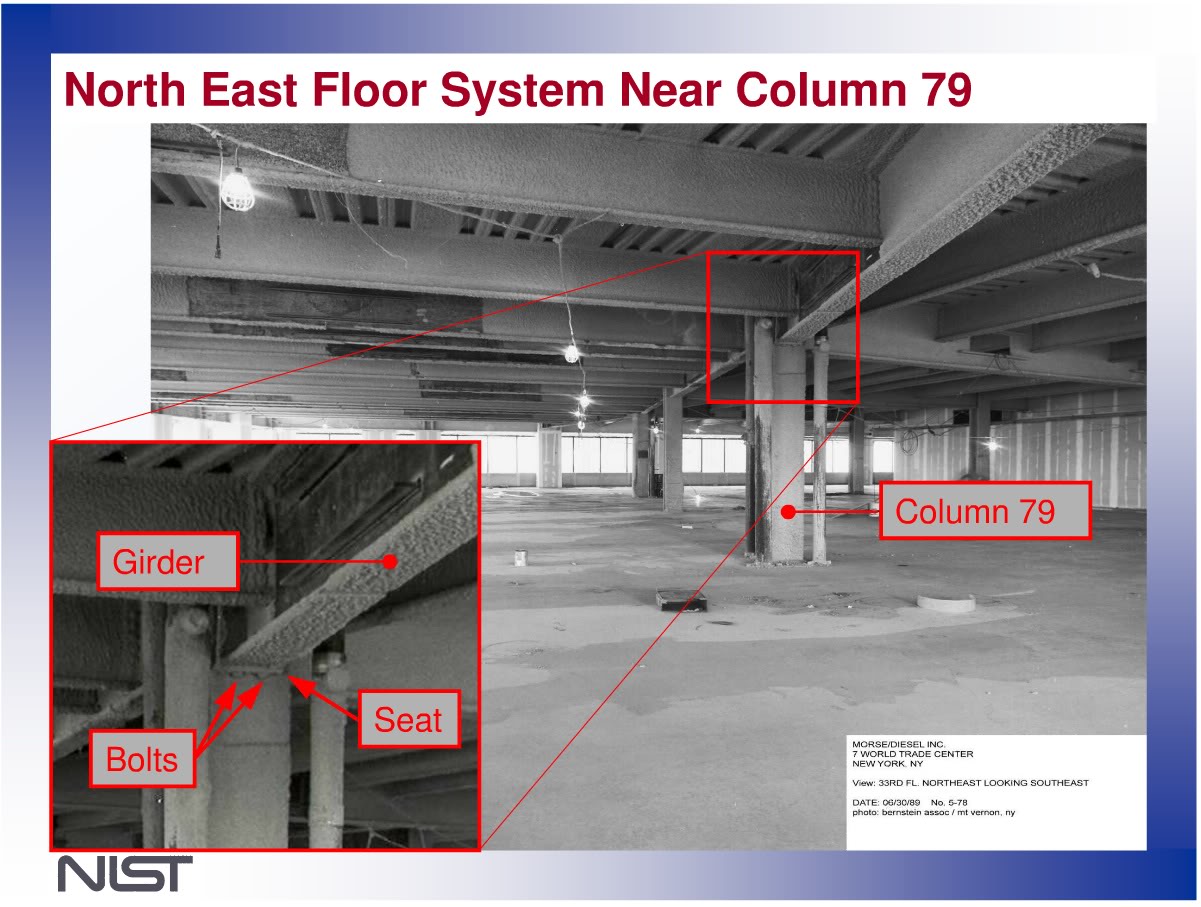

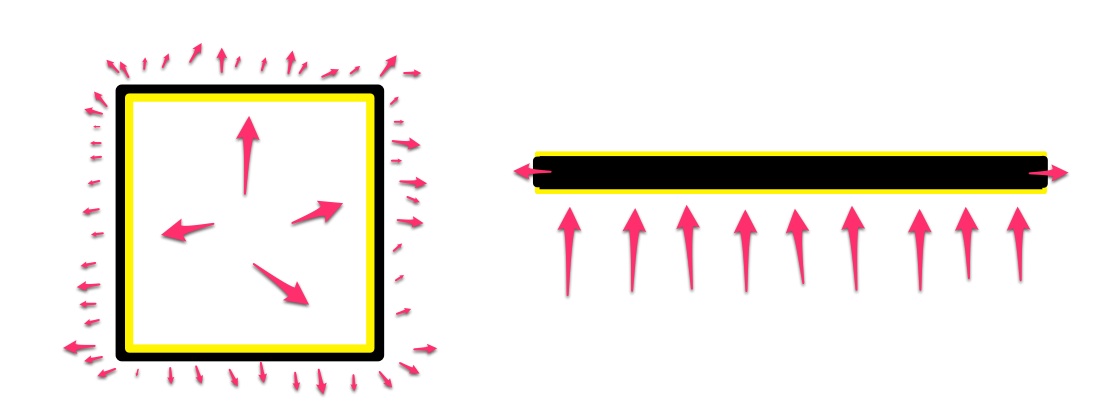

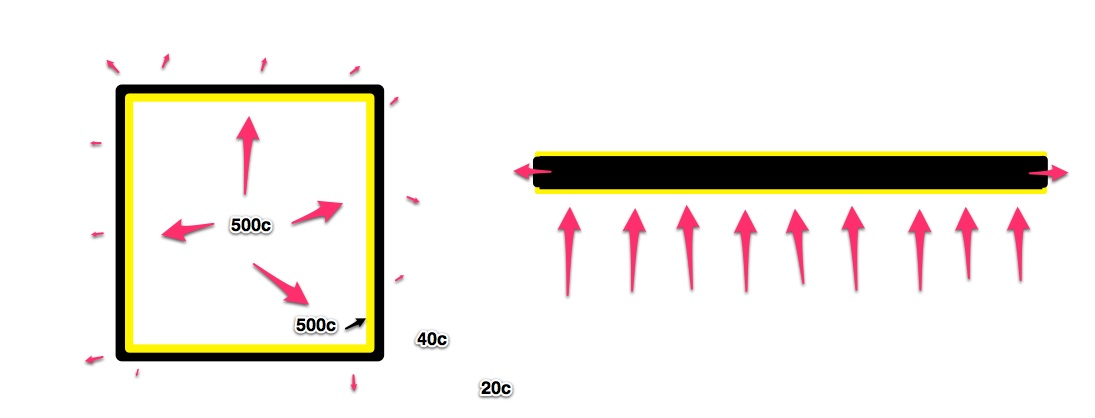

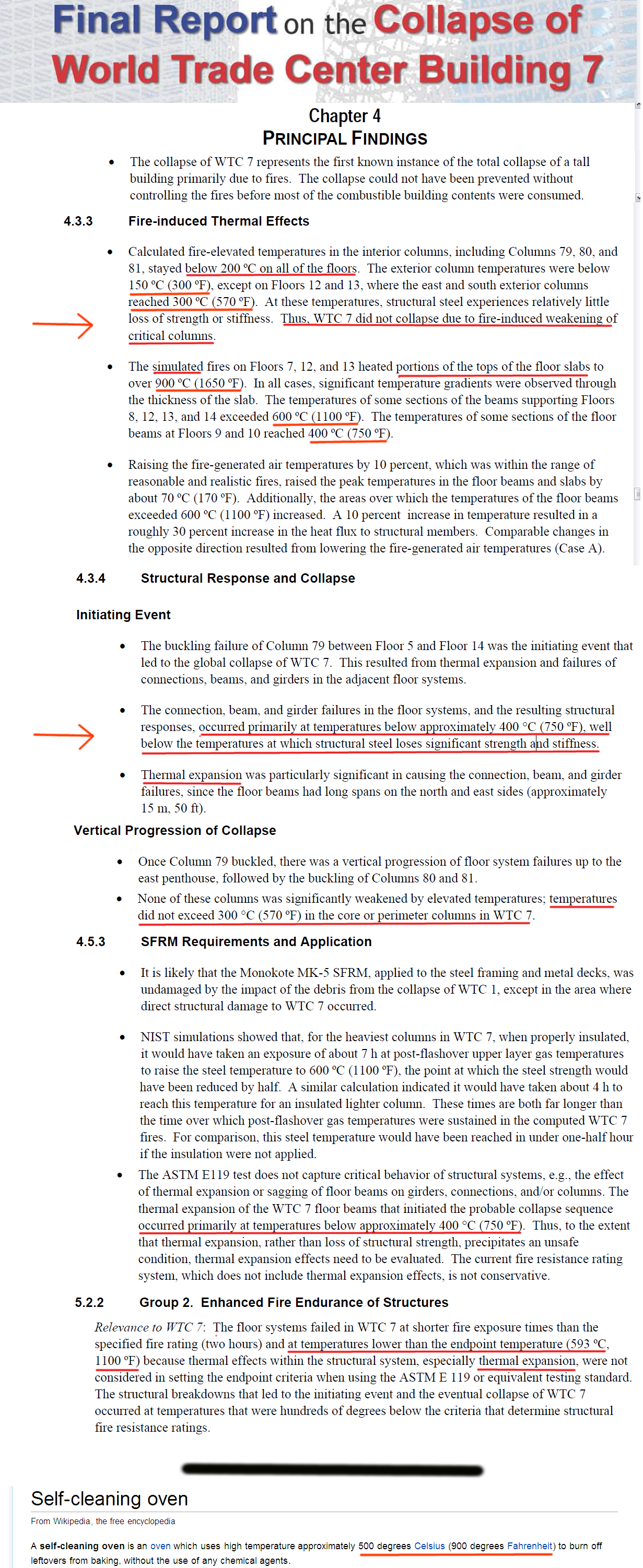

It makes sense because the fires caused multiple failures within WTC7: "An initial local failure occurred at the lower floors (below Floor 14) of the building due to fire-induced floor failures, leading to buckling of a critical column ... Elevated temperatures in the floor elements led to thermal expansion, with or without thermal weakening and sagging, which resulted in failure of floor connections and/or buckling of floor beams. Sufficient floor component failures (connections and/or beams) resulted in at least one unsupported column over multiple floors at the lower floors. This column buckled and led to the initiation of global collapse." NIST NCSTAR 1-9, WTC Investigation 323

And WTC 7 isn't the only building with multi-floor failures due to fire, look at WTC 5: " The uncontrolled fires resulted in complete burnout of most floors and partial collapse of four floors. The building was steel frame construction with field-bolted connections between floor beams and column tree assemblies. Failure of large sections of floor, in areas not damaged by falling debris from WTC 1, resulted from bolt tear-out at these connections as a result of the uncontrolled fires (Figure 8–14). Photographs of two recovered samples of floor beams (Figure 8–15) show how the field bolts tore out from the beam web weakened by the fires (McAllister 2002).

338 NIST NCSTAR 1-9, WTC Investigation"

So, you agree that fires caused the collapse right?

- see above

yes? So you agree that fires caused the collapse right? yes or no?

It makes sense because the fires caused multiple failures within WTC7: "An initial local failure occurred at the lower floors (below Floor 14) of the building due to fire-induced floor failures, leading to buckling of a critical column ... Elevated temperatures in the floor elements led to thermal expansion, with or without thermal weakening and sagging, which resulted in failure of floor connections and/or buckling of floor beams. Sufficient floor component failures (connections and/or beams) resulted in at least one unsupported column over multiple floors at the lower floors. This column buckled and led to the initiation of global collapse." NIST NCSTAR 1-9, WTC Investigation 323

And WTC 7 isn't the only building with multi-floor failures due to fire, look at WTC 5: " The uncontrolled fires resulted in complete burnout of most floors and partial collapse of four floors. The building was steel frame construction with field-bolted connections between floor beams and column tree assemblies. Failure of large sections of floor, in areas not damaged by falling debris from WTC 1, resulted from bolt tear-out at these connections as a result of the uncontrolled fires (Figure 8–14). Photographs of two recovered samples of floor beams (Figure 8–15) show how the field bolts tore out from the beam web weakened by the fires (McAllister 2002).

338 NIST NCSTAR 1-9, WTC Investigation"

So, you agree that fires caused the collapse right?

Last edited by a moderator: