8 Non-Aircraft Systems 8.1 Rocket Powered Glider

An analysis of a rocket powered system was carried out for comparison to airplanes. The concept vehicle utilizes off-the-shelf rocket engines or motors to boost a vehicle and payload to altitude. At apogee wings are deployed to increase the vehicle's lift-to- drag coefficient to allow it to glide at altitude and disperse payload. Once dispersal is completed, the wings retract to allow it to descend quickly.

8.1.1 Cost Estimate

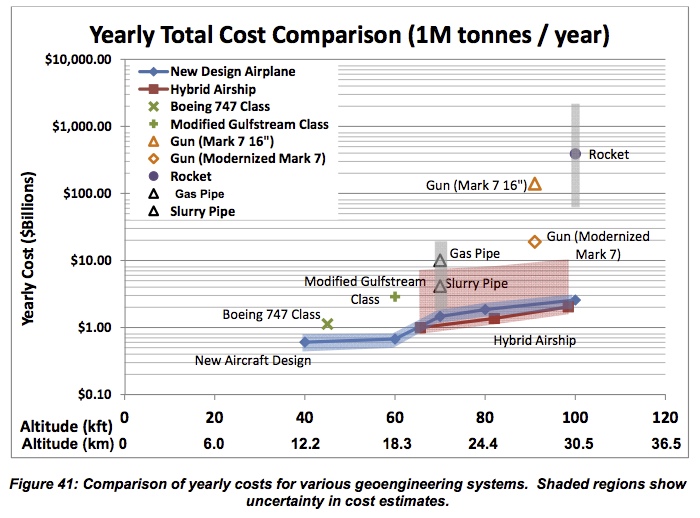

Rocket glider cost estimates were developed; however, a preliminary analysis showed this architecture is far too costly when compared to other systems. An initial estimate for the cost of the rockets was made using the cost per kilogram-payload of existing rocket systems. Both sounding rockets and orbital rockets were examined. Orbital rocket costs per kilogram are scaled down by 1/7 to account for the reduced complexity and energy required to achieve high altitude instead of orbit. Similarly, suborbital rock- ets costs were scaled to equalize costs based on a constant altitude and payload capa- bility (Figure 34). Seven sounding rockets and seven orbital rockets costs were com- pared.

The average cost computed from the 1/7 orbital rocket cost is $2,086 / kg-payload. This is in line with several published values that price a suborbital rocket launch at about $2,000 / kg-payload40. Based on this, our notional 5,000 kg-payload rocket-glider has a fly-away cost of $10M each. At this rate, launching 1M tonnes a year to altitude requires 200,000 vehicles a year and would cost $2,000B per year. It is important to note that these values assume a signal use rocket.

Due to the high acquisition cost of rockets, refurbishing and reusing them is cost effec- tive. Assuming a 1 month turnaround time, reusing the rockets reduces the required fleet to 16,000 bringing total yearly costs down from $2,000B per year to $390B per year. If 10 full time technicians are required to refurbish each rocket, an army of 160,000 technicians is required costing $30B in labor each year.

Rocket motors and engines produce extremely large amounts of energy through con- trolled combustion of highly volatile chemicals. For this reason, a typical rocket has a failure rate of several percent. The top 10 most utilized rockets have a failure rate of 7%, with 1,973 launches between them.41 The Delta 2 rocket has a realized failure rate of 1.35% with 93 consecutive successful launches, the most of any orbital rocket. Be- cause the chemical propellants and oxidizers are carried with the rocket, payload frac- tions are small and a large number of launches would be required to achieve geoengi- neering up-masses. With a 5,000 kg payload, 200,000 launches a year would be re- quired. If rockets can be refueled and refurbished in 1 month, each rocket can fly 12 sorties a year. If no failures occur, a fleet of about 16,000 vehicles is required. If a fail- ure rate of 5% is assumed (note, this is equivalent to retiring a rocket after 20 success- ful launches), a staggering 10,000 rockets will be lost or retired per year. Replacing these rockets dominates acquisition costs requiring a total fleet size of over 216,000 rockets with almost all lost or retired.