they wont need the model in any form.

Made me think though (and apologies in advance for this stream of thought): my model is quite large and heavy, as I wanted to reduce scaling issues a little. And while it would fit in a suitcase, it does take like 20 minutes and a ladder to assemble. This makes it a bit impractical for a roving demonstration. So video might have been more sensible - perhaps with a small section of three floors on one side for illustration.

There are also other problems with wood. It warps, the density changes over time with moisture content, and it chips and breaks with impact.

But (engaging in some wishful thinking) - what if there was a way of making a much smaller model that could also be rapidly and repeatedly assembled? The material would have to be dense (to improve scale issues) and durable (for reuse), so (again, blue sky thinking) precisely machined steel would seem like the obvious choice. This could just be stock steel cut to length. Or maybe even tool steel, which is available sized to very high tolerance, with precise corners (though rather expensive, so probably not).

Using steel instead of wood should (all other things being equal) allow for a much smaller model that gives the same result.

The tricky problem of course is the connections. I first though that magnets wold not work, as it's steel all the way down. But then I realized there's no great need to make the "columns" out of steel. Their primary function in this particular model is supporting strength, not supplying falling mass, so they could be made of something less dense.

This could even be wood again, but I think an ideal solution would be machined aluminum with magnets set in recesses so the surface of the magnet is flush with the aluminum surface (this solves an existing problem of unrealistic force transmission from impacts on the top of the metal plates, and also protects the magnets.

It would also be great to get away from magnets entirely. I keep thinking there must be a sensible alternative out there. Something that's either so cheap you can replace it with every usage, or something that can be "reset" every time.

A connector needs to:

- Provide sufficient vertical support to not fail with the sudden application of the weight of six floors.

- Provide resistance to tension, to give the walls lateral support by holding them in place. (i.e. simply placing the floors on a breakable shelf would not work)

- Provide moment resistance. i.e. resistance to rotational forces. Although the original floors did not do this as part of their specification, having it here gives back some of the function of the missing sides of the building (the Vierendeel truss aspect). If this is not in the connections it would probably need to be simulated in some other way, perhaps with a rear shear plate).

- (Ideally) fail suddenly with little prior displacement.

- (Ideally) fail in a way that leaves the wall surface free of immovable obstacles.

One thing I keep coming back to is recessed ("concealed") cabinet door hinges

These snap to two positions: flat or angled. I'd considered (with the wood model) having them embedded in the side walls, the you could snap them up to form the "seat", and provide tension by hooking in the floors somehow.

Not really very practical though, it's difficult to create the accurate recesses, and the hinges themselves are way more expensive than magnets.

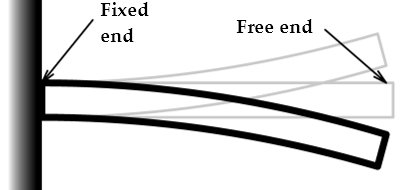

However, I feel there must be something out there that's small and cheap that provides similar functionality. Essentially I'm looking for a bistable structure (of which the cabinet hinge is a complex example), the most common simple example of a bistable structure is a slap bracelet. Another example is a toggle switch (purely from a mechanical perspective), or an animal trap.

Anyway, enough rambling.