Regarding the bid for 83 cubic yards of concrete for earlier repairs:

... and only in the interest of providing some general info about that idea:

Concrete trucks typically carry 10 cubic yards, as pointed out by Boilermaker in his reply about this, but the reason for that is that such trucks are very near the legal load limit for their number of axles and axle spacing. The actual regulations regarding axle loads are quite involved and not really worth quoting in detail for the purpose of this relatively minor point, but anyone who wants to work out the details for California roads can do so using info such as this.

http://www.dot.ca.gov/trafficops/trucks/weight.html

Then considering that an average density for concrete is roughly 4,000 pounds per cubic yard,

https://en.wikipedia.org/wiki/Properties_of_concrete

External Quote:

Tests can be made to ensure the properties of concrete correspond to specifications for the application. The density of concrete varies, but is around 2,400 kilograms per cubic metre (150 lb/cu ft).

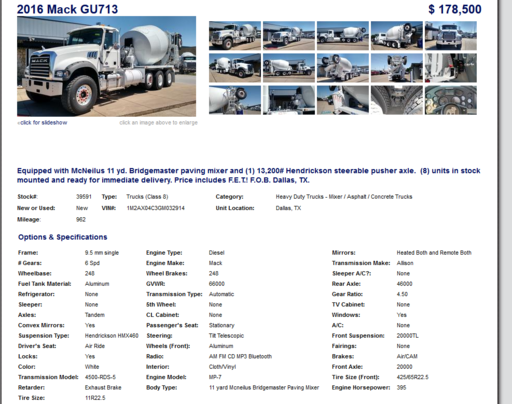

... if we were to assume a moderate allowable load of 34,000 pounds per each group of multiple axles on a truck (this figure was picked from the load-regulations site linked above, and chosen because of the moderate axle spacing associated with it) , carrying 83 cubic yards of concrete would require the truck to have 10 groups of axles with the number of axles per group being not less than two. So in this example, the truck would need 10 tandem-axle sets (perhaps "only" 9 sets if a single steering axle could be rated to carry the leftover weight), which is far in excess of what you'll see on any normal truck. This can only be considered an approximation of course, given how the axle loading was chosen, but at least it illustrates that carrying 83 cubic yards in one batch would require a very unusual truck.

That semi-trailer with the 83-cubic-yard capacity illustrated by Boilermaker, had one tandem-axle set for the trailer and presumably one more for the tractor, plus a steering axle, so it would only be suitable for carrying low-density materials, and I believe he showed that picture just to give us a sense of scale regarding the necessary volume of material.

Edit: I overlooked something important. I ignored the weight of the truck and that amplifies the problem which I tried to illustrate even more. I'm not sure why I'm having so much trouble finding an official source stating the weight of an average 10-yard mixer truck, but here's a site that says 26,000 pounds, and a truck designed to carry a lot more than 10 yards would have a substantially greater curb weight.

https://www.reference.com/vehicles/much-concrete-mixer-truck-weigh-4336f32d54cf0931

External Quote:

Q:

How much does a concrete mixer truck weigh?

A:

Quick Answer

Cooper Concrete calculates that an unloaded concrete mixing truck with a capacity of 10 cubic yards weighs approximately 26,000 pounds. A loaded truck of the same size can weigh as much as 66,000 pounds.