Sausalito

Active Member

Last edited by a moderator:

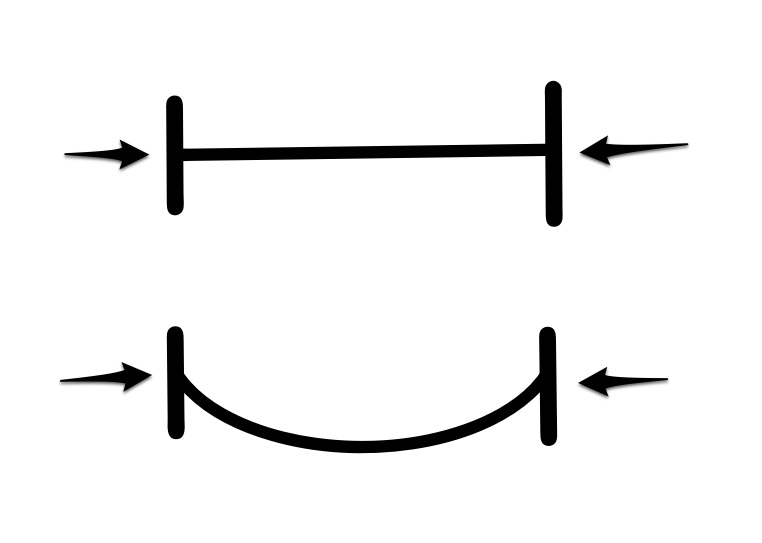

Heat straightening is a repair procedure in which controlled heat is applied in specific patterns to the plastically deformed regions of damaged steel in repetitive heating and cooling cycles to gradually straighten the material. The process relies on internal and external restraints that produce thickening (or upsetting) during the heating phase and in–plane contraction during the cooling phase. Heat straightening is distinguished from other methods in that force is not used as the primary instrument of straightening. Rather, the thermal expansion/contraction is an unsymmetrical process in which each cycle leads to a gradual straightening trend. The process is characterized by the following conditions which must be maintained:

When these conditions are met, the material properties undergo relatively small changes and the performance of the steel remains essentially unchanged after heat straightening. Properly conducted, heat straightening is a safe and economical procedure for repairing damaged steel.

- The temperature of the steel does not exceed either (a) the lower critical temperature (the lowest temperature at which molecular changes occur), or (b) the temper limit for quenched and tempered steels.

- The stresses produced by applied external forces do not exceed the yield stress of the steel in its heated condition.

- Only the regions in the vicinity of the plastically deformed zones are heated.

Irrelevant. Indeed - off topic. Create a thread for it and I will discuss this idea.Since we're about to engage in an interesting debate over the effects of heat straightening <snip> ergo steel is not necessarily weakened by heat deformation

Boston on page 1 said:I'd estimate that metal to be somewhere in the 900+ degree C range or roughly 1700 degrees F

It must be you holding yourself back.So you confirm it is not molten steel. Thanks.

Steel melts at a temperature a further four hundred degrees Celsius greater than that.

This is one of these cases where we are in perfect agreement. Don't let me hold you back...

Got a link to that statement by the way. I don't really feel like searching all night for it

you might want to read the thread before commenting, we just went over how jet fuel does not burn hot enough as a turbulent diffused flame to melt or even significantly weaken steel. Outside of a controlled burn, like in a jet engine where the elements of fuel are joined in the optimum stoichiometric proportions and under pressure. Multiple links have been provided from both industry and distributors concerning the characteristics of jet fuel. Not only did the jet fuel burn off almost immediately, but the remaining fuel boils at fairly low temps, so it really doesn't have an opportunity to remain as a liquid for any length of time in an extremely hot environment.

Or show us a sample of this fuel taken from the base of the towers

prefect, thanks, there's been a lot of water under the bridge even in just a few days and I couldn't remember where that post was from.

So the next question is, how much strength does steel loose when subjected to heat deformation. Like what we see in that burning pool of fuel experiment. What do the tests on that piece of steel show ? I'm going to suggest that the steel in your example was not subjected to the fire long enough to heat the steel to a degree where its significantly weakened. It was however obviously subjected to enough heat to induce heat deformation. One side being heated and the other not will produce warping, but is a warped piece of steel weaker than one that is straight and has the tensile strength been significantly effected in the process of heat deformation.

Also I think a pool of jet fuel is not a laser flat floor ( OK the introduced laser leveling some time after these buildings were constructed but never the less ) which will shed a fluid over a much larger area and in a much thinner layer. So again I don't think this test lies within the context of the situation we are discussing.

Oh and just a tid bit, the arch is one of the strongest structural shapes known.

Oh and just a tid bit, the arch is one of the strongest structural shapes known.

because as long as the ends are secured an upside down arch is quite strong structurally, check the steel cables on the GG bridge.

from

http://www.google.com/imgres?imgurl...2&tbm=isch&um=1&itbs=1&sa=X&ved=0CDwQrQMwCDg8

Test 6: The office demonstration test fire at Cardington:

A compartment 18m wide and up to 10m deep with a floor area of 135m2, was constructed on the second floor, using concrete blockwork. The compartment represented an open plan office and contained a series of work-stations consisting of modern day furnishings, computers and filing systems. The test conditions were set to create a very severe fire by incorporating additional wood/plastic cribs to create a total fire load of 9.4 pounds per square foot (46kg per square meter). Less than 5% of offices would exceed this level (mainly office libraries). The fire load was made up of 69% wood, 20% plastic and 11% paper.

The steel columns were fire protected but the primary and secondary beams (and their connections) were not. The maximum atmosphere temperature was 2215°F (1213°C) and the maximum average temperature was approximately 1650°F (900°C). The maximum temperature of the unprotected steel was 2100°F (1150°C) with a maximum average temperature of about 1750°F (950°C). The steel beams would have only have had 3% of their strength at 2000°F (1100°C), with such little remaining strength left in the steel, the beams could only contribute as catenary tension members. It is also clear that the concrete floors were supplying strength to the structural system by membrane action

This link is a gold mine containing hundreds if not thousands of references in support of molten or near molten steel found at WTC

http://www.google.com/imgres?imgurl...2&tbm=isch&um=1&itbs=1&sa=X&ved=0CDwQrQMwCDgU

How was its tensile strength effected

Why don't you just tell me what you mean. Speak plainly please.again

Can you define what is a caternary tension member ?

Seem rather irrelevant, because if it sags then it's gone past the expansion phase.I'd also be curious as to how you'd think that loss of lateral resistance would affect its ability to push ? something like, oh say, a girder ?

I provided film evidence of molten steel but just for fun, I'll provide some more.

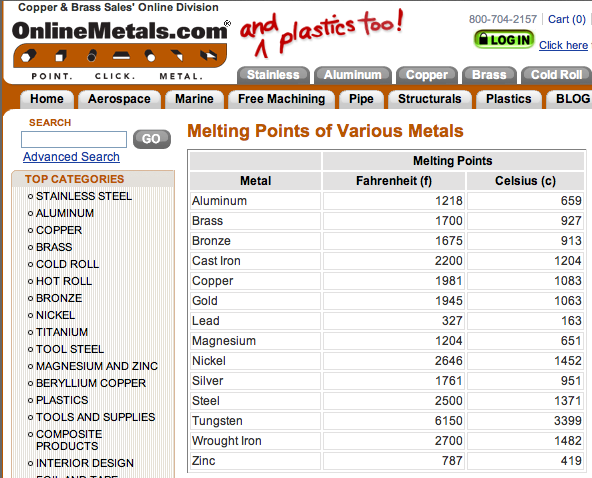

If it were metal it would have to be steel as copper, brass, and alloys melt before they are hot enough to show an orange/yellow color.

I wanted to know what in this picture says that glowing metal is steel? What I see is possibly a refer FAU unit or a electrical control box. the dangling strands of copper wire or pipe and possibly melted brass or alloy dripping if it is dripping. just a thought. it would explain the lack of heat transfer.

It isn't a reflection of anything.I have watched numerous examples, in foundries and any red/orange appearance and the aluminium is not molten yet, when it is molten with a colouring, it is a reflection of the item it is contained in, usually an alloy that can take these temperatures and is glowing red-orange hot.

Not if they were already ash, and burnt already. They would still glow though..And if it was particles mixed in, they would float and demonstrate flame

The evidence shows it is definitely neither steel nor thermitic iron. It could be either aluminum, lead, or zinc. There were large amounts of all three in that locality.This time the available evidence says NOT aluminum, but definitely molten metal

A true debunker? What would you know of that? LOL.A true debunker in pursuit of truth must admit this or squirm to make lies out of science.

Since even NIST concluded temperatures of the fires scarcely reached temperatures of a degree to even melt aluminium, we should now turn round and say oh yes they did.

External Quote:

The melting point of steel is about 1,500 degrees Celsius (2,800 degrees Fahrenheit). Normal building fires and hydrocarbon (e.g., jet fuel) fires generate temperatures up to about 1,100 degrees Celsius (2,000 degrees Fahrenheit). NIST reported maximum upper layer air temperatures of about 1,000 degrees Celsius (1,800 degrees Fahrenheit) in the WTC towers (for example, see NCSTAR 1, Figure 6-36).

http://www.nist.gov/el/disasterstudies/wtc/faqs_wtctowers.cfm

External Quote:

We can all pluck figures off NIST but Pete i suggest you refer to the actually measured temperatures they stated.

J think we can refer to our sense of vision. It's possible to look through the tower window spaces at THE COLOR of the interior. It is ORANGE wherever you look. That is the color equivalent of 1100 deg C. So the temperature of all interior surfaces within the tower fires that one can see is 1100 deg C.We can all pluck figures off NIST but Pete i suggest you refer to the actually measured temperatures they stated.

I suggest you go back to school. http://en.wikipedia.org/wiki/Planck's_lawNow Jazzy. You disagree on reflection. I suggest you look harder, i was not talking of the tower, i was talking in multiple foundry videos, and others where aluminium is melted. I have yet to see aluminium pour red or orange anywhere. Show me an example. And talk of small pools? Well i have seen large amounts poured, and since the larger pool the larger area the faster it will cool the idea it is orange or red because it is a large pool is not solid.

Beauty lies in the mind of the beholder. So does ugliness.There seems to be a basic problem here. Debunker mindset. Not Sceptic or real debunking.

Plastic at the temperature within the building would already have boiled off and burnt.Logically the liquid is not any wood or paper or plastic, ( i know you want to say plastic but the viscosity of it in a melted state will not allow streams of it. If you challenge that prove it. I have seen plenty plastic burn in large quantities and small, it emits black smoke, and drops away from the main body if held over something so it will be subject to gravity, it then falls in flaming globs.

It has the same specific gravity as the metal that surrounded it (aluminum). It is arguable that in places it would have melted and mixed with the liquid surrounding it.Glass-No, it takes temperatures in excess of 1200 degrees for that.

There wasn't enough copper present to account for the observed falling metal.Now you want to suggest copper or other alloys show me where that was and how. Since copper molten is actually a far brighter colour than the observed.

I didn't need to ask them because I have been a foundry worker, and have poured and cast all the materials we are talking about.All any of you need to do is go to a foundry and ask them. please pour out Aluminium/Copper/zinc/tin etc at this height, and show it (the height) and the colour it runs.

Well, you haven't my experience and don't know me, but your statement seems self-applicable to me.You won't because you are NOT interested in truth at all.

Such materials would already have burnt. The fire was an hour old.Jazzy you can disagree with me any which way you like but lets be clear, wood paper and plastics do not fall at the same rate, or burn at the same rate, or burn the same colours. So there is no debris in this.

A sole point of agreement.It IS a metal.

Steel at the observed color is SOLID, so the liquid stream is not iron or steel. Also dirty liquid iron would spit and explode sparks which would themselves spit and explode.How to identify it? Cooling rates over height, colour. That is about all we have to go on. Well based on what i have seen so far, colour matches with molten iron well and even better with steel. The fall rates i have not been able to find a good enough example from a pour from a reasonable height, but i have seen the sparks or tiny drops i should say, come off of steel and iron, as opposed to other metals they have not.

I don't call NIST wrong. That's your business.Additionally, You guys are meant to be OVB's so if you say NOT aluminium, then you call NIST liars and Mistaken, which is fine by me, because you have called the official version a lie on other aspects before, so long as that enables the official version to be true still. Which is a bit of con if you ask me but the more you say Nist are wrong or the FBI are wrong, i am happy to see that on record.

There were around sixty tons of mostly sheet aluminum alloy broken up in a room which was at 1100 deg C for an hour. There's nothing to prove.But if you do-You must prove what it IS. If you do not, then it is quite easy to see it is NOT Aluminium at all, so you are just wrong.

But it does. http://en.wikipedia.org/wiki/Planck's_lawAnyway i have no more to say on the subject until i see your tests of Aluminium, after all i show one thing and the al. Is too small, i would show another it would be too big, another and not heated as much as you want. So you do the tests and prove your wild aluminium that glows red/orange when aluminium doesnt do that. Idea

It's your mind playing tricks with you. Tame it.Or, tell me what else it is.

How will that change that you saying NIST concluded temperatures were not high enough to melt aluminium is a falsehood?

J think we can refer to our sense of vision. It's possible to look through the tower window spaces at THE COLOR of the interior. It is ORANGE wherever you look. That is the color equivalent of 1100 deg C. So the temperature of all interior surfaces within the tower fires that one can see is 1100 deg C.

BARRY

Orange is the colour equivalent in metals but the flames are not the metal colours and what we have to recall is a few points 1. The temperatures were not 1100 degrees, even as the ludicrous claim Pete made it extends to 1000 degrees- So again, you want to exceed the official version or call it into question, in order to make it work.

To clarify AGAIN what i said. Aluminium seen in foundries and fire pits, had the appearance of orange/yellow or red, because of the fires or containers, once poured, the liquid appeared silvery. Now if you disagree that the red/orange appearance is the aluminium not the coals/fire or container glowing red/orange. Show me an example of aluminium POURING red/orange

JAZZY

Beauty lies in the mind of the beholder. So does ugliness.

BARRY

And?

JAZZY

Plastic at the temperature within the building would already have boiled off and burnt.

It has the same specific gravity as the metal that surrounded it (aluminum). It is arguable that in places it would have melted and mixed with the liquid surrounding it.

BARRY

Perhaps, i did not say it WAS plastic i said, the liquid CAN'T be plastic because it would not run in streams and would not glow yellow/orange, it would, if it moved at all, fall in flaming globs. So don't try to debunk something i didn't say.

As for aluminium around it? It won't "mix" i suggest it is YOU that needs schooling because liquid aluminium and other materials don't mix at all.

JAZZY

There wasn't enough copper present to account for the observed falling metal.

BARRY

Then we just concurred it is not-again i did not say it was yet you try to make it sound as though i did

JAZZY

I didn't need to ask them because I have been a foundry worker, and have poured and cast all the materials we are talking about.

BARRY

Well then you know 100% that aluminium doesn't pour red/orange or yellow. However, in that capacity it should be easy to source a video that can show clear aluminium, and it melts, shows the temperature it is at yellow stage etc, then pour it. If it comes out yellow or orange and falls for what is apprx 36 feet and then fades. You have proven your aluminium case

JAZZY

Well, you haven't my experience and don't know me, but your statement seems self-applicable to me.

Such materials would already have burnt. The fire was an hour old.

There were around sixty tons of mostly sheet aluminum alloy broken up in a room which was at 1100 deg C for an hour. There's nothing to prove.

BARRY

Wrong ! The molten metal we see in images pours from the South tower. A tower that was destroyed in 56 minutes. So the plane crashes and the fuel spreads and the fire grows, this takes more than an instant, it would take some time for the air temperature to reach 11000 degrees (which even NIST do not cite that high) But lets say it takes a 5 minutes to spread and take hold and really get roaring. Then that is not an hour at such temperatures at all. Also it demands that the plane which was aluminium is all in the flames and 1100 degree temperature, and all this other aluminium be pooling in one place and pour from the two sources we see in the public domain. Rather than pouring from multiple places as one may expect, whereas a thermitic reaction that caused molten metal, would have a higher chance of being in isolated locations

JAZZY

Steel at the observed color is SOLID, so the liquid stream is not iron or steel. Also dirty liquid iron would spit and explode sparks which would themselves spit and explode.

BARRY

I disagree, and again, wherever something did melt, it has to run a course to get out the tower, so it is already cooling.

JAZZY

Thermitic iron would be a blue-white color surrounded with dense white clouds of alumina. It could not fall outside the building, because it would melt a path vertically down. "Vertical" means "inside".

BARRY

I am not seeing blue here? and in daylight the smoke visible off such a stream would not be easy to see especially at the distance seen from.

JAZZY

I don't call NIST wrong. That's your business.

BARRY

But debunkers are doing this. NIST itself as well as other agencies are calling the official version into question just to prove it, i am therefore of the opinion that 1. There cannot be any contradictions permissible in a report that has such magnitude whether NIST/FBI OR ANY.

2. If you're going to lump all conspiracy theorists as nutters based on some very wild theories (Which does happen)

That is like showing a image of a bowl of water and saying "is it a sea"?

You reference glowing camp fires no smoke, that is totally misinformation. What one would be better to do is show a fire started in daylight or a real housefire.

The smoke of a campfire will not be noticed once it has started and is burning dry fuels and is well established.

The show of anything that is not molten iron and molten aluminium is misleading.

The simple facts are when aluminium is molten it is silver-It requires to be heated hotter to become orange.

So assume it IS Aluminium-it flows straight from the window (again assuming it is EXACTLY next to the window) It then drops over visibly 3 floors still glowing (that is 36 feet) then the glow disappears. So, it could be that it takes a drop of 36 feet to cool molten Aluminium to silver and thus invisibility to the eye at that distance.

Test and prove that.

I have seen numerous examples of aluminium heated to red or orange state, poured into a cast INCHES away, it cools rapidly to silver appearance.

Objects caught in and burning? that implies that the debris is the bulk of the falling items and entirely within the aluminium not floating ON and creating flames.

But all of these items, extinguish themselves around the same time, since it is observable that falling paper is on fire even as they drop to the ground, and since one can take woods, plastics and other items and drop them and they extinguish at different levels indeed, it is highly unlikely that all the objects would "go out" at the same time. So the truth is this is not debris colouring this metal. It is therefore a simple argument of aluminium or another metal.

So the answer Test it.

You are so very fond of demanding proof and debunking anything not sensible, yet provide campfires and coal fires (things that never glow silver, only orange/yellow)

That is specifically choosing the evidence to fit the result not fitting the result to the evidence.

Since even NIST concluded temperatures of the fires scarcely reached temperatures of a degree to even melt aluminium, we should now turn round and say oh yes they did.

Well they can't deny their own theories just to make their own theories work, then decide that both theories are still correct.

Since the logic says molten iron, the onus is on the other side to prove otherwise.

So, go get a few soda cans, get some coals set it 12 feet off the ground, melt the aluminium to orange heat (recording the temp), and then tip it into a mold. If at 12 feet we see no glow. Then it must have been some other metal. If we do see glowing raise it to 24 feet, repeat. And if by 36 feet the height of 3 floors as we see in the videos. Then it IS aluminium case proved.

Simple science. No need for showing people wood fires to prove metal types. That would be like me showing wine to prove what liquid a frozen cube is.

I look forward to your tests

I am not so sure since there is clear degrees of separation between the parts there, whereas the towers had a clear stream THEN sparks/ separation

Also i note the blue white colour of flames-Does that not coincide with what Jazzy said, so this is a thermite induced fire?

What time did this tower collapse in ( i am assuming it didn't have a hat truss)