|

|

|

Mark R. Ferran BSEE scl

JD mcl "Iron Burns!!!" |

Below is a series of E-mails between

Mark R. Ferran BSEE scl

JD mcl and various members of the "Scholars

for 911 truth", in which he attempts to educates them on how Iron burns. Not only does it burn/oxidize, but it can burn/oxidize at low temperatures.

Sent: Tuesday, June 20, 2006 3:18 PM

Subject: WTC IRON BURNS!!!

The only likely source of the heat great enough

to actually "melt" significant quantities of

iron in the piles (or even just raise so much of

it to red-hot or to 2000F) would be chemical

energy (i.e., "combustion" of some sort).

Professor Jones assumes that all the

carbonaceous "combustible" matter in the "piles"

would have burned away long before the time that

the red-hot and molten iron was discovered

(weeks after the collapse of the WTC

towers). Perhaps it did, by weeks after the

collapse. But Professor Jones obviously does

not comprehend that the hot, red-hot and

molten IRON IS COMBUSTIBLE matter.

Here, Jones clearly missed it, when he wrote:

"At

these temperatures, steel will melt, and aluminum materials from the buildings

should continue to undergo exothermic

oxidation reactions with materials also

entrained in the molten metal pools including

metal oxides which will then keep the pools

molten and even growing for weeks despite

radiative and conductive losses. ... The

government reports admit that the building fires

were insufficient to melt steel beams -- then

where did the molten metal pools come from?"

http://www.physics.byu.edu/research/energy/htm7.html

Jones has no clue because he has conception of

Steel Burning (iron oxidation) in air.

The Truth is that: HOT STEEL WILL CONTINUE TO

UNDERGO EXOTHERMIC OXIDATION REACTIONS WHILE

EXPOSED TO AIR, CAUSING IRON TO INCREASE ITS

TEMPERATURE UNTIL IT MELTS, FORMING POOLS OF

MOLTEN IRON.

Professor Jones' comments and conjectures about

the origin of the alleged molten iron

found within the three huge piles of combustible

matter burning after the collapse of the WTC

towers, distinctly prove that Professor Jones is

oblivious of the fact that Iron Burns in air.

For perspective, I found this children's

educational webpage that further illustrates

that "Professor Jones" (among the "9-11

Scholars") is an incompetent

ignoramus because he ignores the

scientifically provable (or

disprovable) fact that Iron metal itself

burns, and that when amassed in large piles

can ignite fires (and can even melt

itself). The article discusses child-safe

experiments observing a very slow oxidation

of iron (rusting at room temperature), but

also mentions:

"Sometimes a big load of iron in a

ship can get hot. The heat can even set

other materials on fire. That’s

because the iron is rusting, which means

it is burning very, very slowly. Iron

rusts in a chemical reaction called

oxidation. That means the iron

reacts with oxygen gas from the air.

Oxidation is the chemical reaction that

occurs when anything burns in air. Like

most oxidations, rusting gives off

heat."

Beyond the scope of this child-oriented

article, it is important to understand that

general rule in chemistry that most chemical

reactions (e.g., oxidation of iron) are

accelerated by higher temperatures. This is

especially true of iron oxidation. This

means, that the hotter iron metal in contact

with oxygen is, the faster it will oxidize

(burn). For example, it is a familiar sight

at iron foundries to see hot iron rust

forming instantaneously on red-hot iron

beams. This hot rust usually falls

off spontaneously (because of the difference

in thermal expansion properties between iron

and rust). Meaning, a hot iron beam, if

combined with a large enough number of other

hot iron beams in a confined or semi

insulated pile (e.g., covered with cement

dust), will burn CONTINUOUSLY until

it consumes itself, (and thus will appear to

have been "vaporized" to those not looking

for the rust residue). It will just thin

away (and turn into rust), as illustrated by

this photo of burned and thinned I-beam

metal recovered from the rubble of the WTC

towers:

Ancient Wisdom about burning iron:

Thomas Aquinas and other theologians

remarked on the famous burning property of

Iron:

Aquinas maintains that:

The head causes an influx of sensation

and motion to all members of the body.

... [S]omeone can understand “to flow

into” (“influere”) in two ways according

to the spiritual sense and mode. One

mode as principal agent: And thus it

belongs to God alone to provide an

influx of grace in the members of the

Church. In another mode instrumentally:

And thus even the humanity of Christ is

a cause of the said influx; because as

Damascene says ... as iron

burns on account of the

fire conjoined to it, so were the

actions of the humanity of Christ on

account of the united divinity, of which

the humanity itself was an instrument.

Christ, nevertheless, according to the

two last conditions of head [governance,

influence] is able to be called head of

the angels according to human nature,

and head of both according to divine

nature; not, however, according to the

first condition [namely, sameness in

nature], unless one takes what is common

according to the nature of the genus,

according as man and angel agree in

rational nature, and further what is

common according to analogy, according

as it is common to the Son along with

all creatures to receive from the

Father, as Basil says, by reason of

which he is said to be the first-born of

all creatures, Col. 1:15. 16

http://www.unav.es/cryf/georgemaritain.html

DAMASCENUS, (lib. 3, cap. 17) wrote:

"For not according to its [the

flesh's] own operation, but by the Word

united to it, He wrought divine things,

the Word displaying through it His own

operation. For glowing iron

burns not by possessing in

a natural manner the power to burn, but

by possessing this from its union with

the fire. Therefore in itself it was

mortal, and on account of its personal

union to the Word, quickening."

http://www.iclnet.org/pub/resources/text/wittenberg/concord/web/

augsc-05.html

19th Century:

"Iron commences to 'burn' at

2500[F], while at the end of the

operation in the Bessemer process,

when the temperature reaches some

3000[F], the iron burns violently,

as demonstrated by examination of

the Bessemer flame with the spectro-

scope. (See p. 46, Vol. II.)"

Manufacturer and

builder / Volume 3, Issue 6, June 1871

Iron smiths (Blacksmiths) modern and ancient

are aware that glowing Iron Burns:

"With

bellows blowing additional air through

the fire, it can reach temperatures of

about 3,000° Fahrenheit. Iron burns at

2,800°, however, so the smith has to be

careful to not ruin his work! … The

smith's fire contains too much oxygen to

allow iron to melt; as it approaches its

melting point the iron burns instead."

Also of note: Faraday's lectures and a

demonstration of iron powder burning

incandescent in air (and more brightly

in pure oxygen):

http://www.fordham.edu/HALSALL/MOD/1859Faraday-forces.html

(" Michael

Faraday was the son of a blacksmith, and

was born at Newington Butts, near

London, September 22, 1791.")

A WWII witness in Germany recounts seeing

the "iron" of three Russian tanks

"burn" from March 9, 1945 until November 3,

1945:

http://members.tripod.com/~radde/RaddesFlight.html

(" The three

Russian tanks before Bresin still burned as

we passed by them on the morning of 11-3,

and this taught me something surprising:

iron burns.") This account

suggests that the "critical mass" of iron

metal that will sustain itself burning hot

may be quite small compared to the

huge amounts of iron debris the WTC piles.

This account of prolonged iron combustion

also supports the conclusion that the main

source of high heat in the piles of the

WTC 1, 2 and 7, weeks and months after their

collapse, was due to burning iron in these

piles. This conclusion could be readily

verified or disproved through simulation or

experimentation.

The other interesting thing about

"iron fire" (fast oxidation of iron) is

that it creates a "vacuum" of sorts that

"sucks" oxygen to itself. Ordinary

carbonaceous "fire" creates carbon

monoxide (CO) or carbon dioxide (CO2),

which are gases that can take the place

of consumed oxygen (02) gas. Carbon

monoxide production releases two

molecules of CO gas per one O2 molecule

consumed. Thus, such a carbon

fire requires a "convection" current to

remove the hot carbon mon/dioxide (out

the top) to make room for more cold

oxygen to be brought in (at the

bottom).

By contrast, an "iron fire" converts

the oxygen gas (and possibly also

nitrogen gas, but that is tangent) into

a solid (rust). Thus, the burning

iron metal effectively sucks atmospheric

oxygen INTO the pile of burning metal,

regardless of convection currents.

Convection currents are a strong

mechanism for REMOVING heat from a

fire. Of course convection currents

will also be present even in a huge iron

pile furnace, but a result of direct

conversion of oxygen gas into a solid

(rust) is that there are weaker

convection currents and that means that

the heat of combustion escapes more

slowly from the metal fire furnace than

from a carbonaceous fire furnace. Thus,

since the heat of combustion does not

leave with the combustion products, a

metal-air furnace could become

much "hotter" faster than a carbon-air

furnace of the same scale (e.g., at the

same oxygen demand level).

Theoretically, there is no limit

upon the temperature that such a large

air-metal-fire could attain. It could,

in theory, attain a temperature high

enough to not only melt iron, but also

to boil (vaporize) iron, but not at the

same location at the same time. (You

cannot maintain solid, liquid, and

gaseous iron at the same location,

because "melting" and

"vaporization" occur at greatly

different temperatures). The difficulty

with that however is that the molten

(burning) iron would tend to settle into

a pool, having a smaller surface area

(on its top surface only), thus

reducing its rate of oxidation.

It has also been suggested that Sulfur

especially from tons of decomposing

Gypsum (a Sulfur ore used in sheetrock

walls and partitions in offices and

homes) in the piles accelerated the

oxidation or melting of the iron

burning in the piles. "Sulfur is widely

distributed in nature. It is found in

many minerals and ores, e.g., iron

pyrites, galena, cinnabar, zinc blende,

gypsum..."

http://columbia.thefreedictionary.com/Sulpher

"Dust and debris deposits

associated with the September

11, 2001, terrorist attack on

the World Trade Center have left

a distinct fingerprint on the

sedimentary record in New York

Harbor, scientists have found.

Their results appear in the

January 21, 2003, issue of the

journal EOS, a publication of

the American Geophysical Union.

... The high levels of calcium,

strontium, and sulfur

concentrations found in the

near-surface sediments ..., are

consistent with presence of

gypsum as a parent material.

Gypsum is extensively used as

drywall in building

construction."

The "Sulfides" produced when

sulfur dioxide (e.g., from

decomposed Gypsum) contacts

burning iron have been

identified as an agent that

supposedly accelerated the

"deterioration" of the steel in

the burning WTC piles, on a

macromolecular level.

"A section of an A36 wide

flange beam retrieved from

the collapsed World Trade

Center Building 7 was

examined to determine

changes in the steel

microstructure ...

Rapid

deterioration of the steel

was a result of heating with

oxidation

in combination with

intergranular melting

due to the presence

of sulfur. The

formation of the eutectic

mixture of iron oxide and

iron sulfide lowers the

temperature at which liquid

can form in this steel. This

strongly suggests that the

temperatures in this region

of the steel beam approached

~1,000ºC, forming the

eutectic liquid ...."

http://www.tms.org/pubs/journals/JOM/0112/Biederman/Biederman-0112.html

In other words, Sulfur Dioxide gas

(e.g., from decomposing Gypsum

wallboard) spontaneously reacts

(combines) with iron metal (cold or

hot), turning it into iron sulfides

and iron oxides (i.e. burning the

iron). The sulfides introduced into

iron (sulfidation) by exposure of

iron to Sulfur Dioxide gas have been

used by humans (blacksmiths) for

hundreds if not thousands of years,

and have been understood in chemical

terms for centuries, but apparently,

such chemistry is not understood by

BYU Professor Jones.

"The formation of the eutectic

mixture of iron oxide and iron

sulfide lowers the temperature

at which liquid can form in this

steel. This strongly suggests

that the temperatures in this

region of the steel beam

approached ~1000°C by a

process similar to making a

“blacksmith’s weld” in a hand

forge. (Barnett, 2001)"

For hundreds of

years, Blacksmiths took advantage of

this well-known property of sulfur

dioxide by "welding" iron parts

together over fires of sulfur-rich

charcoal, which lowers the melting

point of iron at its surface.

Sulfur Dioxide gas

can be released by the burning of

ANY ORGANIC substance, including

wood, paper, flesh, fabrics, and

especially plastics (carpets),

and rubber (rubber is "vulcanized"

by adding sulfur to it). Sulfur

Dioxide gas, has a distinct impact

on the nose, and is a respiratory

irritant, because it forms sulfurous

acid when it combines with water or

moisture in the human body. Sulfur

Dioxide can be further oxidized to

form sulfuric acid (when added to

water). High

concentrations of Sulfurous fumes

emanating from the piles at Ground

Zero have been documented, and have

been identified as a probable cause

of respiratory ailments suffered by

many rescue workers and cleanup

crews.

"One of the America's top

air-quality scientists test the air

around Ground Zero and tells NBC's

Lisa Myers and the NBC Investigative

Team he was shocked to find alarming

levels of sulfuric

acid and fine particles more than

three weeks after the attack.

(MSNBC, October 29, 2003)"

http://www.asthmamoms.com/worldtradecenterarticles2003.htm

Professor Jones

demonstrates his ignorance of the

basic "Blacksmith" chemistry of

sulfidation-by-S02-from-fire with

his following oblivious or dishonest

statements: "Then

there is the rather mysterious

sulfidation of the steel reported in

this paper -- What is the origin of

this sulfur? No solid answer is

given in any of the official

reports. ... While gypsum in the

buildings is a source of sulfur, it

is highly unlikely that this sulfur

could find its way into the

structural steel in such a way as to

form a eutectic. ... Thus, we

find substantial evidence supporting

the current conjecture that some

variation of thermite (e.g., solid

aluminum powder plus Fe2O3, with

possible addition of sulfur) was

used on the steel columns of the WTC

Tower to weaken the huge steel

supports, not long before explosives

finished the demolition job."

In addition to sulfidation of cold

iron by its exposure to sulfurous

(e.g., SO2) fumes, sulfidation by an

even more direct transfer of the

sulfur and oxygen from Gypsum to

Iron might occur where Gypsum (dust)

is in direct contact with the

burning (e.g., red hot) iron.

Another's

lucid rebuttal of Professor Jones'

conjectures about the sulfidated

iron found in the burning piles of

WTC wreckage is self-published as

follows:

"The "absolutely

conclusive smoking-gun PROOF"

amounts to this: Prof. Jones

CLAIMS to have obtained a sample

of solidified spatter from

post-collapse WTC structural

steel. He takes the

sample-gatherer's word that this

is where it came from. He claims

to have determined the sample to

be sulfur-contaminated iron.

Solely from this basis he leaps

to the definite conclusion that

it's a residue of thermate

(thermite with sulfur and

potassium permanganate

additives) used to cut the

tower's columns. This is quite

the leap of inductive

reasoning. As we all know, the

debris field of the WTC was an

oven of steel-melting intensity.

All of the WTC's debris was

churned together chaotically in

this pile. Steel is basically

highly refined iron. The element

sulfur is present in abundance

in many building materials.

Drywall, for example (also known

as GYPSUM board) consists

primarily of plaster, i.e.

gypsum, i.e. hydrated calcium

SULFATE. Churn lots of steel and

gypsum together and cook them

for three weeks at temperatures

sufficient to melt both and I

would not be surprised to see

"sulfur-contaminated iron"

turning up in samples of same.

This is not to say Jones is

definitely wrong as to what

produced it, just that it's

ridiculously dishonest and

irresponsible to hype this as

"absolutely conclusive

smoking-gun PROOF" of the use of

thermate. There is at least one

other completely plausible

completely mundane possibility.

Prof. Jones focuses on the

iron/sulfur mix as a signature

of thermate, but makes no

mention of aluminum oxide, which

would also most definitely be

present and which he'd certainly

test for and mention if it were.

This is a strange omission.

Prof. Jones knows better "

For practical purposes, all this

means that a huge pile of iron

beams (e.g., mixed in with tons of

other materials initially burning) can

itself begin to burn like huge iron logs

in a pile furnace, and there is

no reason not to expect this system to

reach a temperature high enough to melt

iron. Sulfur Dioxide (SO2) gas,

released from burning organic materials,

and/or from decomposing Gypsum, in the

burning piles will spontaneously combine

(react) with cold or hot iron, adding

more heat to the iron, and adding

"sulfides" to the steel and

thus lowering its effective melting

temperature.

The first "molten" iron in the WTC piles

was reportedly discovered WEEKS

AFTER the collapse of the WTC towers,

and molten iron was reportedly found

regularly during the following MONTHS

during excavations of the huge piles.

The only rational explanation for this

steady-state phenomenon is IRON

BURNING. "Professor Jones" is not a

rational man, and thus he fails to

consider the fact that Iron Burns, and

instead assumes that the

reported "molten iron" was all created

(by surreptitious "Thermite") on

September 11, 2001 and that all this

red-hot liquid metal just stayed clumped

together on its chaotic descent down 70+

floors and then stayed in molten form

until it was dug up weeks and months

later.

Further, as an aside, it is total idiocy

for Jones and his associates to assume

that someone intent upon both bringing

down the WTC towers and being undetected

in doing so would go to the trouble of

actually "melting" some of the iron (let

alone allot of it) within the iron

support columns (steel will not "melt"

until reaching temperatures of nearly

3000F), rather than just heating some

of them to the much lesser temperature

point at which the iron would EXPAND

and DEFORM (see photos linked below) and

become worse than useless to support the

enormous weight of the building. (That

temperature can be scientifically

calculated given the load parameters,

and was evidently equal to or less than

the core temperature of the carbonaceous

office fires spanning an

enormous area e.g., one square acre in

size, on each of several floors of each

WTC tower). Note: "A typical house

fire can reach 2000 degrees

Fahrenheit after just five minutes of

flame."

http://www.jsc.nasa.gov/roundup/online/2004/1104_p4_7.pdf

"THE TYPICAL HOUSE FIRE REACHES A

TEMPERATURE OF APPROXIMATELY ELEVEN

HUNDRED DEGREES [Fahrenheit]"

http://www.gia.edu/newsroom/3685/broadcast_content.cfm

Aluminum melts at about 1218 F.

It is an observable fact that virtually

all carbonaceous-fires (e.g., bonfires,

house fires, burning-paper fires,

airplane fires) are readily capable of

melting aluminum. (Note: "Fire" is

not synonymous with "flame".)

When even smaller aluminum aircraft burn

on the ground, the

resulting fire usually "melts" their

aluminum portions, thus proving

temperatures exceeding 1200 degrees

Fahrenheit:

"The forward portion

of the fusilage [sic] containing the cockpit

burned, the aluminum being almost completely

consumed by the heat of the fire which

ranged from 1310 degrees to 2100 degrees

(F)."

http://www.nps.gov/yuch/Expanded/b24/b24.htm

These temperature

estimates exceed the melting point of

aluminum. See also the burning-aircraft

photos in this thoughtful rebuttal of

Professor Jones' lunatic "thermite" theory.

http://www.debunking911.com/moltensteel.htm

("Air France

flight 358 didn't hit a steel building at

500 miles an hour. It didn't even burn the

fuel in the wings yet it's aluminum skin

melted to the ground. It simply went off the

runway and caught fire. What melted the

airliner was the contents like seats,

clothing and other combustibles including

chemical oxygen generators. It's not

unreasonable to conclude the airliner and

contents didn't even need the contents of

the building to melt.") (unfortunately, the

author of that article also mistakenly

assumed that iron is "non-combustible")

[edit by Debunking911: I am correcting this with the

inclusion of this page.]

It should also

be kept in mind that "aluminum ...

ignites at relatively low temperature,"

Aluminum, "melts at about 1,220[F] degrees.

At about 1,400[F] degrees, it can

automatically ignite and burst into flames

without any spark" "The formation of

aluminum oxide is accompanied by the release

of a tremendous amount of heat ...

temperatures can reach around 5,000

degrees."

http://www.dmanuta.com/dmm/aluminum.doc

More information

about aluminum is provided here:

http://www.911myths.com/WTCTHERM.pdf

(although I think he tends to oversell the

role of melted aluminum in the collapse of

the WTC)

In other words, why use readily

DETECTIBLE "thermite" (or even

"explosives") when just burning tons of

paper, plastic, rugs, aircraft-chairs,

clothes, flesh, computers, (perhaps

aluminum metal), and some hydrocarbon

(jet) fuel, would (and evidently did)

accomplish the same result?

Professor Jones is an attention whore, who

does not check his facts:

The essay at

http://www.cagenweb.com/quarries/articles_and_books/

stone_magazine/fire_trap.html by an

early American civil engineer of great

repute ( William Sooy Smith,

1830-1916) explains the known

weaknesses of Iron (steel) beams and

columns exposed to fire. He notes that

the primary mechanism of structural

failure in steel buildings is the

DESTRUCTIVE FORCE generated in the steel

itself when it EXPANDS due to heating by

FIRE. He describes the destruction of

several steel frame buildings due to the

heat of fire, including one in New York

city. In view of these examples, there

is a warning (or prophesy) by the Fire

Chief of the City of New York of the

eventual collapse of a very tall steel

frame building, (such as the World

Trade Center buildings), due to exposure

to the heat of fire. His essay is

essential reading for anyone who would

express or consider an opinion about the

likelihood that a steel framed building

exposed to fire would be brought down by

the heat of fire.

Excerpts:

1) "Witness the Manhattan Savings

Bank building, Broadway and Bleeker

street, New York, which was

destroyed a few weeks ago by the

heat generated in the burning of

the ... building next to it."

2) "fire ... partly destroyed the

Athletic Association building in

this city. ... and it is evident

that if this heat had continued but

a little longer the whole structure

would have fallen."

3) "And notably at the burning of

the Tribune building in Minneapolis,

about three years ago, which

resulted in its entire destruction."

"There may be steel buildings in

which the fireproofing has been so

well done that they will pass

through an ordinary fire without

such failure. But if the steel

becomes even moderately heated its

stiffness will be measurably

diminished, and the strength of the

upright members so reduced as to

cause them to bend and yield. This

is more likely to occur, as the

horizontal beams and girders will at

the same time expand (unequally from

the different degrees of

temperature) and throw the posts out

of vertical and into buckling

positions. This is the third

difficulty. ... The third

difficulty, resulting from the

expansion and contraction of the

metals employed in the construction

of tall buildings, may be obviated

by protecting these metals

absolutely from any considerable

change in temperature..."

Chief Bonner, of the fire department of

New York, says in reference to the

destruction of the Manhattan Bank

building:

....We shall

have in this city, unless the

citizens of New York are warned in

time, a calamity by fire which will

rend their hearts. ... The heat

thrown from a large burning building

of any height is immense. ... I

am prepared to declare, from my

experience, that a building of brick

and yellow pine in case of fire is

easier to manage, and the contents

have more chance of being saved than

the modern fire-proof building. In

the former structure the fire burns

more slowly and has no chance to

concentrate its heat as in the iron

and steel structure.

Chief Swenie, of the Chicago fire

department, is quoted in the essay as

follows:

"I think very

much as Bonner does," said Fire

Marshal Swenie to-day, when his

attention was directed to a

statement of the chief of the New

York fire department to the effect

that the modern skyscraper is a

veritable firetrap. .... Fire in a

room so filled with goods might in

very short time gain such headway as

to imperil seriously the entire

structure by the expansion, warping

or twisting of the iron or steel

framework.

No ...

building of any kind in which

inflammable goods are stored should

ever exceed 125 feet in height, and

might with advantage be much less.

This is not because we cannot throw

water high enough. But suppose such

goods are stored in a twelve-story

building; a fire breaks out, say on

the sixth floor, and gets to burning

furiously. The heat

ascends and causes the

pillars and beams to expand.

The expansion first raises all that

part of the building above where it

takes place. At the same time the

whole weight above continues on the

expanded metal. before you know

where you are something

is going to give, and

what will be the results? They will

be too fearful to contemplate.

...

It does not take a great

amount of heat to cause steel and

iron to expand, and

when beams and columns begin moving

something has got to

break. Suppose a fire

breaks out in one of these

buildings. We work at it from below,

and the steel beams expand, the

ceiling breaks and the floor above

comes down. ...

The statements of Professor Jones and others

that "almost

no fire, even one ignited by jet fuel, can

cause structural steel to fail"

are insane distortions of reality and

misrepresentations of practical experience

of fire-fighters and engineers (See

http://www.whatreallyhappened.com/spain_fire_2005.html

A fire in a Madrid steel-frame building

collapsed 10-story sections of the building

-even without a plane crash weakening those

sections-, and almost brought down the rest

of it, which had to be torn down. "At its

peak, temperatures reached 800 degrees

Celsius (1,472 F)" ) See also:

http://enr.construction.com/images2/2006/02/060206-30A.jpg

Professor Jones' irresponsible claims

disparaging the capacity of fire to damage

and collapse iron/steel

structures are readily proved false by

photographs of iron beams distorted and

large sections of buildings collapsed by

fire, including those photos of the

distorted iron beams in the highway bridge

that I include (below).

As for Jones' claims that a molten metal pooled

and pouring out of the floors near where the

planes impacted was necessarily iron, not

aluminum: How does Jones "get rid of" the

Molten Aluminum that would result from contact

of the airplane parts with the alleged molten

iron? Molten iron in contact with solid

aluminum will produce molten aluminum and solid

iron, or motel aluminum and molten iron (i.e.,

always molten aluminum). The molten metal

emerges (only) at the same corner and at

the same floors of the WTC where the aluminum

body of the aircraft "gently landed." What a

coincidence. Also, it almost certain that much

of the aluminum of the aircraft had melted in

the heat of the fire(s), so if "iron" can "pool"

there and pour out as Jones claims, why wouldn't

some of the tons of molten aluminum (which just

happened to land there) also pour out? What

happened to the molten aluminum according to

Jones? Jones only asserts that melted aircraft

aluminum "would

flow away from the heat source ... Thus, the

observed molten metal flowing from WTC 2 on 9/11

cannot be aluminum."

Why would melted aluminum "flow away from the

heat source" if not by action of gravity and the

shape of the surface (floors) it was pooled on?

Molten Iron would follow the same path as molten

aluminum. And, why does Jones suppose that "out

a window" is not "away from the heat source"?

Why would (pooled?) molten iron have a

preference over pooled molten aluminum to flow

"away" out of a window from the same location?

More fundamentally, what good is molten iron

falling out of a window to someone who wants to

use it to HEAT a VERTICAL IRON BEAM to the point

of failure???? In order to USE thermite to heat

something, you have to let the molten iron

transfer its heat to that thing, which means

that the molten iron would cool and solidify

if were actually USED to heat something. And,

since Jones claims that the thermite was placed

on the internal columns of the building (since

they failed first), how and why would molten

iron show up at the outside perimeter (near a

corner) to fall out of a window? Thermite

charges are always used ABOVE (or inside) the

subject to be heated, because any other position

would result in the hot molten iron formed by

thermite flowing down away from the subject to

be heated and being useless waste. Jones

offers no explanation for why anyone would go to

the trouble of using "thermite" to produce many

gallons of WASTE molten iron that was not kept

in intimate contact with vertical Beams and

therefore served no purpose other than to fall

out of a window and attract attention to

itself. So, shall we call Jones' Theory: The

Theory of the Incompetent Thermite Bombers Who

Just Needed to Call Attention to their Handiwork

by Pouring Molten Iron out of a Window. Or,

maybe the Airplanes were really Hijacked by

well-intentioned American Patriots who knew that

the only way to expose the secret plot to

destroy the WTC with Thermite was to fly a plane

into the buildings at exactly where the Thermite

was installed to hopefully cause some of its

residue to fall out a window where the World

could see it and certainly know that it was

"molten iron" produced by thermite. Bless their

souls.

Jones writes:

"Who can deny that liquid, molten metal existed at

the WTC disaster? The yellow color implies a

molten-metal temperature of approximately 1000

oC."

Jones admits that: "We

note that aluminum has many free electrons, so it

reflects ambient light very well -- and it appears

'silvery'. Aluminum ... aluminum would appear

silvery due to high reflectivity combined with low

emissivity..."

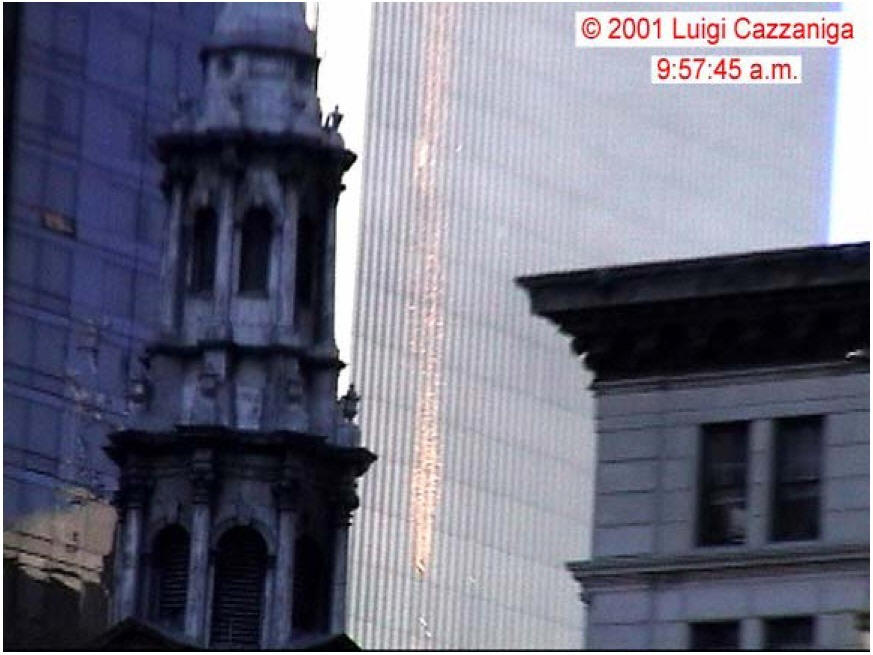

Look at the shiny blocky highly reflective

(silvery) solid masses that were produced from

the falling (cooling) molten metal, seen in the

bottom of the photo above right. Is it solid

Iron, or solid Aluminum?

I believe that it may be possible to "prove"

that the molten metal falling out of the WTC was

aluminum based on its behavior (e.g., breaking

up in the air, failure to "spark" white all

around, and turning into a blocky silvery solid

while falling). Aluminum is much less massive

(dense) than iron, so molten aluminum will be

more affected by air resistance than molten iron

would be. See the horizontal shift of the

falling molten metal in both of the photos

above. (E.g., Aluminum would be broken up out

of a poured stream (or blown to one side) sooner

than heavier molten iron) Also, at any given

temperature, molten iron would

probably be differently viscous or would

have different surface tension than molten

aluminum. Thus, it would visibly behave

differently upon being poured of a window. The

photos show molten metal pouring out of the WTC

that appears to be somewhat widely dispersed

(and shifted horizontally) by wind and air

resistance, suggesting that it is lighter than

iron. [It just does not quite "look" like a

stream of heavy liquid iron.] Experimentation

or simulation could prove or disprove this

hypothesis.

Keep in mind also that Jones is oblivious that

hot (molten) Iron Burns spontaneously in air.

Another problem with Jones' theory that this

falling molten metal is "iron" (and not

aluminum) is that IF it were IRON, at the

temperature of melted iron, some of it would

probably have constantly been seen

exploding/flashing/burning into bright white

Light upon being released as small particles in

the air. " The

smith's fire contains too much oxygen to allow

iron to melt; as it approaches its melting point

the iron burns instead."

http://www.osv.org/cgi-bin/CreatePDF.php?/tour/index.php?L=12&PDF=Y

Read Faraday's demonstration of moderately

heated iron particles burning in air, producing

"scintillations".

" I have here a

circular flame of spirit of wine, and with

it I am about to show you the way in which

iron burns, because it will serve very well

as a comparison between the effect produced

by air and oxygen. If I take this ring

flame, I can shake, by means of a sieve, the

fine particles of iron filings through it,

and you will see the way in which they burn.

[The lecturer here shook through the flame

some iron filings, which took fire and fell

through with beautiful scintillations.]"

http://www.fordham.edu/HALSALL/MOD/1859Faraday-forces.html

Absent constant bright White "flashes" of

burning iron droplets/particles, it more

probably was aluminum at or near its melting

temperature. I have "poured" molten aluminum

that I got by melting scrap in a

wood-fire, short distances, and that did not

readily produce flashes of light (maybe because

it cools down faster in cold air than it can

oxidize), although it theoretically can.

(molten aluminum is fairly tame) I have not

"poured" molten iron, but see this photo showing

the smaller iron droplets burning bright WHITE

in air during even a very short pouring

operation at a foundry:

And, see all the bright white sparks flying in

this series of photographs of an iron pour:

Dante observed and wrote about this commonplace

property of poured molten Iron, in his The

Divine Comedy:

"I could not endure it long, but enough to

see him sparkle all round, like

iron poured, molten, from the furnace.

And suddenly, it seemed that day was added

to day, as though He who has the power, had

equipped Heaven with a second sun."

http://www.tonykline.co.uk/PITBR/Italian/DantPar1to7.htm

Also, more definitely, the falling molten

material clearly turns into a silver colored

(highly reflective) (flat, blocky) solid

material after it cools (as soon as it stops

glowing) after falling down a number of stories

(strongly suggesting aluminum metal, not iron).

Solid iron is generally not that highly

reflective without polishing, but aluminum

is. [Molten iron would probably not loose its

glow and convert into a solid so quickly, since

it does not conduct heat as well as aluminum and

because it would be formed much hotter than

molten aluminum.

Also, iron would be expected to coalesce

into a rounder clump while falling before

solidifying. [Shot towers are used to form iron

ball-bearings, and lead musket balls, out of

poured molten metal. But, there is no

indication that aluminum can be formed into

round balls by this method, perhaps because it

cools down to quickly] If the "shot tower"

behavior of iron (forming spherical balls of

molten iron before solidifying) holds with

larger amounts of poured iron, then the molten

metal pouring out of the WTC, IF IT WERE IRON

WOULD HAVE FORMED CANON-BALL SHAPED gobs of

molten metal before it cooled down and

solidified.

The falling metal pieces formed by that

pour out the window of the WTC tower are clearly

NOT ROUND and are very elongated, or

flat, indicating a very rapid cooling of the

falling poured (aluminum) metal. [These

distinctions can be readily proved or disproved

by experimentation or calculation]. Jones

does not comment upon the silvery flat,

blocky, (not round) metal pieces visible falling

in the photo frames in his own thesis.

The NISC report seems to agree:

"The composition of the flowing material can

only be the subject of speculation, but its

behavior suggests it could have been molten

aluminum." (p. 375)

There is of course the possibility that the

falling molten metal was some other material

from the airplane or offices other than aluminum

or iron. But, I believe that there is enough

information from the video to scientifically

determine its approximate density and also its

Specific Heat, its melting/solidifying

temperature, and its thermal conductivity. The

latter determinations could be based on standard

formulas used to determine cooling rates due to

"forced convection."

"A few department chairmen at Jones'

university have issued critical statements,

though none of these has yet addressed any

of the points which Jones made in his paper

and at his presentation at BYU. Chairman of

the BYU department of Civil and

Environmental Engineering, Dr. Miller, is on

record stating in an e-mail, "I think

without exception, the

structural engineering

professors in our department are not in

agreement with the claims made by Jones in

his paper, and they don't think there is

accuracy and validity to these claims."

About Professor Jones, associated

with the so-called "9-11 Scholars"

website, I previously wrote (to

him) substantially the

following assessment of his wacky

half-baked theories about thermite

and molten iron:

Speaking as an engineer of high

academic achievement, I am

shocked that Brigham Young

University has employed an

ignorant moron of such epic and

treasonous proportions. I will

be further shocked if he is not

removed promptly from

his position of trust and

confidence. It has been my

understanding that the Latter

Day folks are a close knit group

who watch out that their members

far and wide do not embarrass

the community. In other words,

it is my hope that the Latter

Days will take the initiative to

contact the leadership at BYU so

that justice to the truth may be

served.

Excerpt of published assertions

by BYU professor Jones:

"Jones argues that

the WTC buildings did

not collapse due to

impact or fires caused

by the jets hitting the

towers but collapsed as

a result of

pre-positioned "cutter

charges." Proof, he

says, includes:

. Molten metal was

found in the

subbasements of WTC

sites weeks after 9/11;

the melting point of

structural steel is

2,750 degrees Fahrenheit

and the temperature of

jet fuel does not exceed

1,800 degrees. Molten

metal was also found in

the building known as

WTC7, although no plane

had struck it. Jones's

paper also includes a

photo of a slag of the

metal being extracted

from ground zero. The

slag, Jones argues,

could not be aluminum

from the planes because

in photographs the metal

was salmon-to-yellow-hot

temperature

(approximately 1,550 to

1,900 degrees F) "well

above the melting

temperatures of lead and

aluminum," which would

be a liquid at that

temperature.

.... No steel-frame,

high-rise buildings have

ever before or since

been brought down due to

fires. Temperatures due

to fire don't get hot

enough for buildings to

collapse, he says."

Having seen first hand the

rubble of the WTC on the night

of September 11, 2001, I can

tell you there was fire and

fires everywhere around the

scene, and fumes rose steadily

from the "piles" after the

collapse, and fumes continued to

rise from the piles when I went

back to Ground Zero over a week

later. As I described it " I

saw a hellish vapor slowly

rising everywhere from the

rubble like something out of

Dante [Inferno]." See:

While Leaving Ground Zero -

September 11, 2002

http://www.federalobserver.com/archive.php?aid=4108

(Note, I am not the same "Mark

Ferran" as the NYC fireman by

that name, and we have never

met) When I first heard about

the fires in the WTC buildings

that morning, I said to myself,

in my office, that the metal

must be getting very hot. When

I later saw the images of smoke

and fire billowing out of those

buildings, I knew they would not

stand. After they fell, the

huge piles of iron beams and

combustible materials formed two

enormous furnaces, comprising

burning office materials,

burning metal, and burning human

flesh (not to mention many tons

of combustible aircraft aluminum

and iron, i.e., thermite) which

over the course of several weeks

and months. It was widely

reported that the temperature

(e.g., measured by infra red

imaging from above) in the

interior of the piles INCREASED

in the weeks after the collapse

of the towers, due quite

obviously to the combustion

of combustible matter in these

large furnaces.

The moron employed at BYU seems

to have no conception of the

nature of a furnace, no concept

of the fact that metals

burn, and seems to be unable to

comprehend that there were much

combustible materials in the

piles from the collapsed

buildings OTHER THAN what the

airplanes brought in.

"[W]hile the jet fuel was

the catalyst for the WTC

fires, the resulting inferno

was intensified by the

combustible material inside

the buildings, including

rugs, curtains, furniture

and paper [and humans, and

aluminum of the planes].

NIST reports that pockets of

fire hit 1832°F [even before

the buildings collapsed]."

The jet fuel was the

ignition source," Williams

tells PM. "It burned for

maybe 10 minutes, and [the

towers] were still standing

in 10 minutes. It was the

rest of the stuff burning

afterward that was

responsible for the heat

transfer that eventually

brought them down."

http://www.popularmechanics.com/science/defense/1227842.html?page=4&c=y

Even ordinary dry WOOD

(charcoal) in a large enough

furnace, is capable of melting

iron:

While a mixture of aluminum and

(oxygen and iron) (e.g., rust)

called "Thermite" is capable

of producing molten

iron, evidently, a combination

of metallic Iron and Oxygen (or

Carbon Monoxide) is itself

capable of melting iron in a

large pile furnace. Large piles

of pure iron dust are capable of

"burning" themselves into a

molten mass solely due to the

heat of combustion of the iron

itself. Iron itself

is a combustible material

(and is commonly used in powder

form to warm hands and feet in

little packs sold at Wal-Mart

etc., and in MREs).

I believe that

these photos (below, and seven

images at

http://www.debunking911.com/truck.htm) fairly illustrate

the type of expansion,

distortion and yielding that

most likely happened to destroy

some of the iron columns

supporting the enormous weight

of the World Trade Centers' top

30+/- floors.

http://www.debunking911.com/alabamatruck1.jpg

The iron

columns of the WTC towers did

not "melt" in the scientific

sense of the word, but they

certainly EXPANDED (due to

heat), and yielded (due to the

enormous pressure caused by

their own thermal expansion).

Just turn these above pictures

from horizontal to vertical, and

think what would happen if that

beam were instead a column

holding up a heavy

building. (Look at the distorted

iron, heated by ordinary

hydrocarbon fuel burning, and

keep in mind what Professor

Jones said: "almost

no fire, even one ignited by jet

fuel, can cause structural steel

to fail." ) Also

note how the metal of the fuel

tank itself so completely

disintegrated. (see the

other photos at http://www.debunking911.com/truck.htm).

It's tank may have

been made of flammable aluminum

metal, like the skin and

structure of a jetliner, or of

stainless steel. I believe

that the fires confined inside

the world trade center towers

could have been much hotter than

this fairly "open air"

(unconfined) gasoline fire, due

to the greater containment of

the heat-of-combustion by the

ceilings, floors and debris in

the burning WTC towers. See http://www.zmag.org/interactive/content/display_item.cfm?itemID=3944

The False Leaders of the

so-called "9-11 Truth" movement

typically do not understand or

don't acknowledge the power of

ordinary FIRE nor the

known weaknesses and behaviors

of iron exposed to fire, and

they peddle their false

explanations of occurrences to

people even more ignorant than

them. They are the blind

leading the blind. Most of the

uneducated people (e.g.,

WebFairy,

Lisa

Guliani, Victor Thorne

etc.) selling videos books,

etc., claiming that "fire could

not have destroyed the WTC

towers" are just pathological

liars who will tell any lie to

take a buck from the gullible.

Furthermore, there is no such

thing as a "maximum temperature"

for the combustion of any dry

fuel. If you raise the

temperature of a dry fuel, like

paper, or wood paneling, or

charred flesh, and then expose

it to oxygen, its temperature

will INCREASE, not remain the

same. Duh!!! The bigger the

furnace, the higher the

temperature of the unburned fuel

gets before it combines with

oxygen, and thus still higher

will its temperature be when it

finally combusts. "Temperature"

inside of a furnace system is

solely a function of how much

heat enters the system versus

how much leaves the system, over

time, and not a function of the

type of fuel. Insulation, or a

large enough mass, slows the

exit of heat from the

system. (Note: melting things

removes energy from a system) A

large pile of debris forms an

insulating furnace retaining

much of the heat of combustion,

raising the internal

temperature, evidently high

enough to melt iron. That is

how the ancients used piles to

make and refine and melt iron

from ore.

It is shocking that a

"professor" would assume that

molten iron found weeks or

months later in the bowels of a

huge pile of continuously

burning debris (containing tons

of combustible iron and other

materials) would have to have

been generated at the very

beginning of the fire, or even

before the pile was formed. It

is even more nonsensical for him

to presume that a molten metal

supposedly formed before the

buildings collapsed would remain

molten for months without

some subsequent source of heat

being applied to it. And, it

is totally absurd for him

to presume that a molten

(liquid) metal supposedly

formed in the top floors before

the buildings collapsed (his

"thermite" theory) would remain

both molten and intact after it

fell 70+ stories in a chaotic

collapse while even more solid

objects (bones, concrete, flesh)

were obliterated on the way

down. The "professor" also

seems to be oblivious that

(aircraft) aluminum is itself a

high-energy fuel, that would not

be found in bright molten form

weeks later (because it burns

continuously when molten and

exposed to air). (They

use Aluminum metal as fuel to

propel the Space Shuttle into

Orbit around the Earth).

Also apparent, is that the

so-called "professor" is

incompetent or lazy in the use

of search engines, such as

Google. On this very subject, I

wrote this back in 2001:

"Furthermore, if it is true

that "pools of molten steel"

were found in the (basement

of) remains of the WTC twin

towers, this molten material

probably began to form and

accumulate days AFTER THE

COLLAPSE of the tower, when

the huge mass of material

trapped the heat of slowed

combustion that continued

within the pile. I saw the

fumes of combustion folks,

the piles were slowly

burning after the buildings

collapsed. Everyone with the

slightest recollection of

the events knows this. Even

a huge pile of iron filings

will form a red-hot fused

mass of metal because the

heat produced internally by

rusting will build up in the

pile. Any combustible

material in the "piles" of

the WTC that was exposed to

heat and to any amount of

infiltrating air (oxygen)

would contribute to

hot-spots. All of the

conjectures that say the

steel formed before the

buildings collapsed are

ignorant and preposterous.

The Steel in the rubble of

the WTC melted, if at all,

because of the enormous size

of the piles and presence of

much combustible materials

in them, not merely because

of the burning of jet fuel.

Those who say otherwise are

either lying, or are

overlooking something

fundamental. While jet fuel

flame burning in OPEN AIR

will may not maintain the

temperature you need to melt

steel, if you inject any

fuel mixed with air into a

huge porous mass that cannot

rapidly release the built-up

heat of combustion, you will

produce a furnace capable of

melting steel or practically

any other metal. An open

flame rapidly dissipates the

heat of combustion, but a

furnace conserves and

accumulates the heat of

combustion. Any fuel will

produce this effect in the

appropriate furnace. Its

like the difference between

the heat of an open

wood-flame of a single stick

burning in open air,

compared to the

(steel-melting) white-hot

heat produced in the bottom

of a large pile of wood and

burning wood-coals. This is

also the principle by which

large piles of organic

materials (e.g., saw-dust,

leaves, hay) will

spontaneously begin to burn-

the heat of decay builds up

inside them. "No matter

which mechanism is involved,

the oxidation reaction will

generate heat. If there is

some form of insulation,

which is usually provided by

the mass of the material

itself, the heat cannot be

dissipated. Because the heat

is not dissipated, the

temperature of the material

increases. The increase in

temperature will in turn

increase the rate at which

the oxidation reaction

occurs, which in turn will

increase the amount of heat

generated, and so on. This

increase after increase

continues until either the

heat is dissipated some way

[e.g. by melting steel], or

the material reaches its

ignition temperature and

starts to burn. (the same

basic process occurs in

stored green bio-mass

materials such as hay, saw

dust, corn cobs, etc. but

the heat is generated by the

life process of

micro-organisms)."

http://bifrost.unl.edu/ehs/ChemicalInfo/flamsol.html

"

"This scientific

principle of a furnace,

understood by primitive

humans since the bronze age,

could potentially destroy

the credibility of anyone

who forwards and endorses

the erroneous theories

(e.g., "nuclear" bombs). You

are literally playing with

fire by promoting such bogus

theories. People, for the

sake of our country, and out

of respect for those who

died at the WTC, please do

not promote or forward those

Urban Legends.

"I am sorry if my words

are harsh, but I do not have

much patience for people who

are either irresponsible for

forgetting what they

themselves saw, who pretend

to understand physical

principles that they have

not studied or otherwise

have no competence in, or

who are simply liars who are

out to make a reputation by

misrepresenting to others

what happened on September

11, 2001. Everyone with

common sense knows that two

commercial air planes hit

and burned inside the towers

and caused the towers to

break and to fall. Mark R.

Ferran BSEE scl JD mcl

http://billstclair.com/ferran/index.html

I am aware that there are

millions of science-ignorant

people and some total morons

walking around America babbling

about the World Trade Center

(and I have tried in vein to

address this http://www.zmag.org/interactive/content/display_item.cfm?itemID=3944

) , but when a "professor" who

knows that he has no formal

education nor any

practical education in the

science of chemistry,

combustion, nor of metallurgy,

nor of the Strength of materials

decides to spew his ignorant

reckless notions as

scientific "FACTS" to the

gullible volatile public at a

time of crisis, I feel that his

reckless conduct warrants

extreme and swift

punishment. Professor Jones has

also misrepresented the

significance of the "Law of

Entropy" to bolster his false

claims. Given the tendency of

this

professor's misrepresentations

to give aide, comfort, and

encouragement to those who have

overtly declared Jihad against

our pathetic country, (and who

must be able to recruit more

jihadists just by laughing at

our domestic morons) I would be

satisfied to see this

"professor" tried, convicted,

and executed for Treason. He

breached a Trust in time of

WAR. Jones' reckless remarks

will probably kill as many

Americans as President Bush's

misuse of the word "Crusade" has

and will.

I think it is preposterous for

anyone to assume that a

tall building or any

conventional material or mode of

construction can not fall down

if you fly a large fuel-laden

airplane into it at more than

500 miles per hour.

In summary, we have a

moron posing as President, and

now we have morons posing as

"Professors" too. No wonder

that the people of the world

increasingly find it necessary

to destroy US for their own

preservation.

Mark Ferran BSEE scl JD

mcl

P.S.

Snopes may be a good starting

point for information to counter

some of the Anti-American

9-11 propaganda (e.g., from the

French):

Sent: Friday, July 14, 2006 7:01 PM

Subject: Re: Professor Jones: WTC

IRON BURNS!!! updated July, 14 2006

Professor Jones of

BYU has since acknowledged in an

email to me the fact that "iron

burns" but attempts to limit

this chemical reaction to only

"under certain conditions" (he

specifies pure oxygen as supposedly

being a requirement), but Jones has

failed to acknowledge that hot Iron

is combustible (it oxidizes and

generates heat) when combined with

ordinary air, and Jones has not

responded to the

following observations that iron is

usually sulfidated upon exposure to

the fumes from ordinary fires.

----- Original Message -----

Sent: Friday, July 14, 2006 7:54 PM

Subject: Re: Professor Jones: WTC IRON

BURNS!!! updated July, 14 2006

MARK: Now we are getting somewhere. Obviously

iron burns at some temperature. At what

temperature does iron reach the condition at

which it burns and at what temperature does

structural steel, which is what was used in the

construction of the WTC buildings, reach the

condition at which it burns? Is the temperature

for the condition which causes the burning of

structural steel higher than that of iron? What

American Society Of Civil Engineers (ASCE)

specification did the structural steel used in

the construction of the WTC buildings meet? Did

the specifications meet the requirements of the

American Institute for Steel Construction

(AISC)?

At what temperature does jet fuel burn?

KEEP up the good work Mark. With a name like

Ferran, we can expect the best information about

ferro!-----BILL

To: William

Cc: Kevin Barrett

Sent: Saturday, July 15, 2006 12:37 AM

Subject: Re: Professor Jones: WTC IRON

BURNS!!! updated July, 14 2006

William, you asked these

innocent questions:

"Obviously iron burns at some

temperature. At what temperature does iron reach

the condition at which it burns and at what

temperature does structural steel, which is what was

used in the construction of the WTC buildings, reach

the condition at which it burns? Is the temperature

for the condition which causes the burning of

structural steel higher than that of iron?"

Fe + O2 -> FOx plus heat.

For example,

4 Fe(s) + 3 O2(g)

----> 2 Fe2O3 (s)

Delta Go =

1487 kJ

Iron wire ("Steel Wool"),

which has a coating of oil to prevent rusting, will

"ignite" and quickly transform the fine iron wire into

iron oxide(s), with just the touch of the small flame of

a match. So, the activation energy/temperature for

fast iron oxidation is not very high relative to the

heat of an ordinary flame fire.

"rusting (oxidation of

iron) is overall very exoenergetic. Even though

under normal conditions the oxidation reaction

proceeds very slowly, there is sufficient energy to

initiate the process at room temperature. Once

begun, the process can sustain and slightly

accelerate itself by using the heat released from

the reaction and that initially available from

room-temperature to provide the necessary activation

energy."

http://www.newton.dep.anl.gov/askasci/chem03/chem03046.htm

And,

"'Rust' is really a

family of iron/oxygen compounds with various ratios

of: Fe, O, and H (as in water). All the 'rusting'

reactions are exothermic to the tune of from about

-60 to -190 kcal/mol That is they all liberate a

substantial amount of heat. In fact one can

generalize that for most metals oxidation is

exothermic. Now the "activation" energy to which you

refer has to do with just how "fast" the reaction

occurs. In the case of iron. I do not have the

numbers in front of me but from qualitative

observation I would expect it is quite small...."

http://www.newton.dep.anl.gov/askasci/chem03/chem03046.htm

Impurities, (e.g., water,

salt) and even some bacteria may promote or

catalyze iron oxidation (rust) at room temperature. You

generally cannot prevent room-temperature iron surfaces

exposed to the environment from oxidizing in air except

by painting it, coating it (e.g., galvanizing), or

combining it with something else (e.g., adding chromium

in to make stainless steel). Structural Steel is not

"stainless steel" and therefore it is chemically

reactive the same as pure iron, for purposes of

oxidation by air.

Pure Iron oxidizes fairly

rapidly at "hot" temperatures. The hotter it is, the

faster an exposed hot iron surface will react (oxidize)

in air, generating more heat. The iron-oxidation

reaction and resulting reactive surface temperature may

be further increased by adding pure oxygen, but that is

not necessary to sustain exothermic (i.e.,

heat-producing) iron oxidation. To get the reactive

surface of a mass of rapidly oxidizing iron to

incandesce bright white you probably have to add pure

oxygen, which will raise the iron-oxidation reaction

rate at the surface, and raise the temperature at the

surface, etc.. Some people would identify this

incandescing phenomena as "burning" iron/steel. But,

even while not incandescing white, red-hot iron exposed

to air is "burning", just somewhat slower.

Red-hot iron exposed to air

IS OXIDIZING, (or "burning"), the only question being

"how fast" is it "burning". In a big deep pile like the

debris piles of the WTC buildings, the iron-oxidation

reaction will probably be moderated by the availability

of atmospheric oxygen. In other words, the reaction

will take place at the rate at which oxygen from

air infiltrates into that part of the pile (e.g., by

convection). [Note that SO2, e.g., generated by Gypsum

decomposing in the piles will also cause additional

iron-oxidation, plus sulfidation] However, the

resulting change in temperature is a function of how

much heat is generated minus how much heat is lost by

convection, conduction, and radiation within a period of

time. Deep inside the piles these losses are relatively

small, and the larger the scale of the red-hot

iron-fire, the smaller these losses are on a per mass

basis. See http://www.tcforensic.com.au/docs/uts/essay6.pdf#search='

temperature%20iron%20combustion'

Professor Jones himself

expressly notes that the pile has "insulating"

properties and would conserve the heat of oxidation, but

Jones overlooks that it is primarily hot IRON that will

be oxidizing weeks and months after the collapse.

You asked "What

American Society Of Civil Engineers (ASCE) specification

did the structural steel used in the construction of the

WTC buildings meet? Did the specifications meet the

requirements of the American Institute for Steel

Construction (AISC)?" as if these specifications or

requirements were somehow related to the oxidation

(burning) of hot structural steel members.

The ASTM or ASCE or

AISC standards do not have

anything to do with the chemical reaction between hot

iron and oxygen.

The AISC does not certify

individual pieces or batches or structural steel. It

only ANNUALLY certifies the methods and procedures of

the manufacturer:

Kevin Ryan committed

deception and was properly fired. Kevin Ryan

falsely asserted:

"We know that the steel

components were certified to ASTM E119. The time

temperature curves for this standard require the

samples to be exposed to temperatures around 2000F

for several hours. And as we all agree, the steel

applied met those specifications."

I looked up what the ASTM

E119 standard actually is. ASTM E119 does NOT test

"steel" nor "steel components" per se as

Mr. Ryan had implied. Rather, ASTM E119

time-temperature tests evaluate whole building

assemblies that include fire-proofing or

fire-resistance:

"ASTM E119, Standard Test Method

for Fire Tests of Building Construction and

Materials, is used to determine the fire resistance

of a complete assembly. For example, a wall system

fire rating is measured by constructing a 10 foot by

10 foot section of a total wall system: framing,

cavity insulation, sheathing, siding, gypsum wall

board, etc. The wall section is installed vertically

on a gas furnace, and the wall is exposed to a

standard temperature curve for the time period for

which a rating is desired, i.e., one, two, three, or

four hours. Failure points during time of fire

exposure are:

"• Flame penetration through the wall section;

"• An unacceptable temperature increase on the

unexposed side of the assembly;

"• Structural failure or collapse of the assembly.

"Therefore, a one hour fire resistance rating is

taken to mean that a structure incorporating the

tested wall construction will not collapse, nor

transmit flame or a high temperature, while

supporting a design load, for at least one hour

after a fully developed building fire."

http://www.pima.org/technical_bulletins/tbull105.html

The chemical and physical or

thermal properties of the framing steel members are

standardized and known, or are tabulated in catalogues,

and determining such are not the object of the ASTM E119

testing. Rather, it is the functionality of the

fire-proofing or fire-resistance of the whole assembly

that is tested. After you crash an airplane into a

building, the ASTM E119 test results become totally

irrelevant, because you have changed the structure, at

least by removing the fire-proofing or the

fire-resistant wall and ceiling materials. The ASTM

E119 certification is intended to estimate how long

the structural steel WILL BE PROTECTED FROM EXPOSURE to

temperatures around 2000F.

There is no "structural steel"

column that is going to continue to support the weight

of a heavy tall building after being directly "exposed

to temperatures around 2000F for several hours". ASTM

E119 certification does not purport to impart such super

heat-resistant properties to structural steel. See also

Kevin Ryan's own words indicate

that he really knew nothing at all about the ASTM

E119 testing that his "company" supposedly performed

on WTC "steel", and that he had no right to

misrepresent it's significance. Hence, he was

incompetent and presumptuous, and he deserved to be

fired, or even sued for fraud, or even criminally

punished.

The only thing Kevin Ryan was

certainly right about is that structural steel in

the standing WTC buildings did not actually "melt"

(to a molten liquid) before the collapse of the WTC

buildings. It did not have to. "It does

not take a great amount of heat to cause steel and

iron to expand, and when beams and

columns begin moving something has got to

break." http://www.cagenweb.com/quarries/

articles_and_books/stone_magazine/fire_trap.html

However, at least some of the

aluminum alloy metal from the crashed airplanes

certainly did actually melt before the collapse, and

that indicates a temperature of about 1,200F in the

infernos at the crash sites.

You ask, "At what temperature does jet

fuel burn?" as if that were a meaningful question.

The answer(s) depend upon what the

temperature of the Jet Fuel is at the moment that it

combines with oxygen, and upon the temperature of the

environment that it is burning in. I have a now-rare

device called a Kerosene flame-thrower that I used to

use to crack/shatter hard rocks and melt glass just

because it's flame was hot enough, and because it was

fun.

There is a coil in the hot end that

transports and pre-heats the kerosene before it is

released out the flame nozzle through the coil.

If you had just poured the same kerosene

onto a rag and lit it up, it would not burn as hot as

the flame coming out of the nozzle of that burner.

If you construct a large enough furnace

in which the temperature of the liquid fuel itself will

be increased to its boiling point and then further heat

the fuel vapor before exposing it to air, then there is

no limit upon the temperature that may be attained by

burning kerosene (Jet fuel) except that the fuel will

decompose into carbon at some high temperature (and thus

cease to be that fuel). A pure-carbon (charcoal) fire

is very capable of melting steel. If you super-heat jet

fuel, you can get pure carbon and hydrogen anyway. So,

depending on the size and configuration of the furnace,

you can melt iron with jet fuel. I do not believe

that flaming jet fuel literally melted any iron in the

WTC towers. No one with any intelligence does.

Mark Ferran BSEE scl JD mcl

P.S. Thank's for noting that my family's

name is derived from the Latin Root word for Iron, Ferr,

Ferro, Ferris. You are the first to notice that.

From: William

Cc: Kevin

Barrett

Sent:

Saturday, July 15, 2006 6:33 PM

Subject:

GETTING DOWN TO BRASS TACKS

MARK: First, I want to thank you

for responding forthrightly

without the accompanying

characterizations ( although

"innocent questions" might fall

into that category).

The

terms oxidizing and burning, in

my mind, represent two states of

the oxidation process. There is

the slow oxidation process at

relatively low temperatures,

such as the oxidation of copper

roofs or gutters or

flashing which produces a

coating on the copper that is

green or the oxidation of

grandma's family silverware

which produces a coating on the

silver that is gray. There

is even a special alloy

steel called Corten steel that

produces a protective rust

coating that serves as a barrier

to further oxidation and

therefore does not require

painting to preserve its

integrity. The Ford Foundation

Building in New York City

used exposed Corten steel as an

architectural enhancement.

The

state of oxidation of the

examples cited is distinctly

different from the oxidation

that takes place with the fire

of fuel oil in the basement

furnace or of the wood in the

ski lodge fire place or of

the fire from propane gas used

to solder the copper pipes. This

different state of oxidation is

like the different states of

water as liquid, or as a solid

ice, or as a gas steam--- they

are all water but in a different

state that require different

temperatures to produce the

different states.

Burning, therefore, is the state

of oxidation that occurs at the

time that ignition temperature

is reached which is generally

when the temperature is

sufficiently high to transform

the oxidizing material into a

gaseous state. It is an ignition

temperature which increases with

the increase in the mass of the

oxidizing material. The ignition

temperature would be lower, for

instance, to ignite steel wool

than the temperature required to

ignite the three inch

thick steel column flanges used

in the World Trade Center Twin

Towers. To prove my point, after

igniting your steel wool with a

match try using a match to

ignite your screw driver.

Furthermore, the product of the

oxidation that produces ferrous

oxide, or copper oxide, or

silver oxide is completely

different than the product of

burning which produces carbon.

So,

to clarify or to be more

precise with the questions I

asked-------

What

is the ignition temperature of

iron and what is the ignition

temperature of the steel

that was used in the

construction of the WTC

buildings? Is the ignition

temperature of structural steel

higher than the ignition

temperature of iron?

What