Is that in a science book, or what? You are joking, right?

Related to the corroded steel how? A fantasy of CD. Appears to be CD, based on zero evidence. Where as, appears to be fire, has many joules of heat energy evidence, photos, fire, and steel fails in fire, and steel structure fail in fire.

What engineering book says explosives are the only know cause for "rapid" slower than freefall, over 16 seconds, building failure like WTC 7. Page number and source please.

Not one building on 911 was a rapid failure. The towers fell at a rate consistent with the structures engineering and design - the Chief Structural Engineer agrees with me. WTC 7, took over 16 seconds to collapse, which is very slow. Ignoring the interior collapse in the WTC for 10 to 12 seconds before the single tracked point of a roof line begins to fall is called what? Ignoring evidence is what in science? Fraud, dishonesty, what is it?

The reality of CD, primary energy is gravity; E=mgh released by tiny amount of explosives, which means gravity is the main driver. Thus, the only known cause of rapid total tall building failure is gravity. This is in science books, where as the process of CD being the only way for building to fall down is not in science books, it is made up by 911 truth. And how do we relate this to corroded steel, most likely occurring after 911 in the debris piles.

The only engineers on earth who claim the evidence free CD nonsense are in 911 truth, and represent less than 0.1 percent of all engineers. Much less, because no 911 truth source has polled every so called engineer 911 truth claims to have support from. Which means 911 truth is backed for the fantasy of CD at much less than 0.01 percent of all earth's engineers.

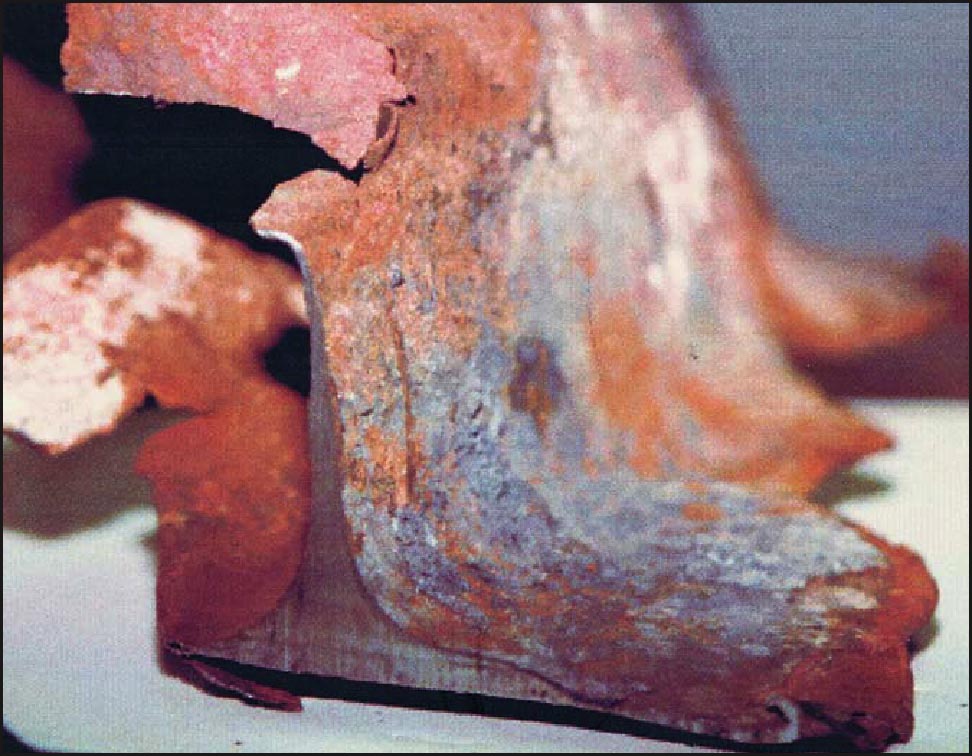

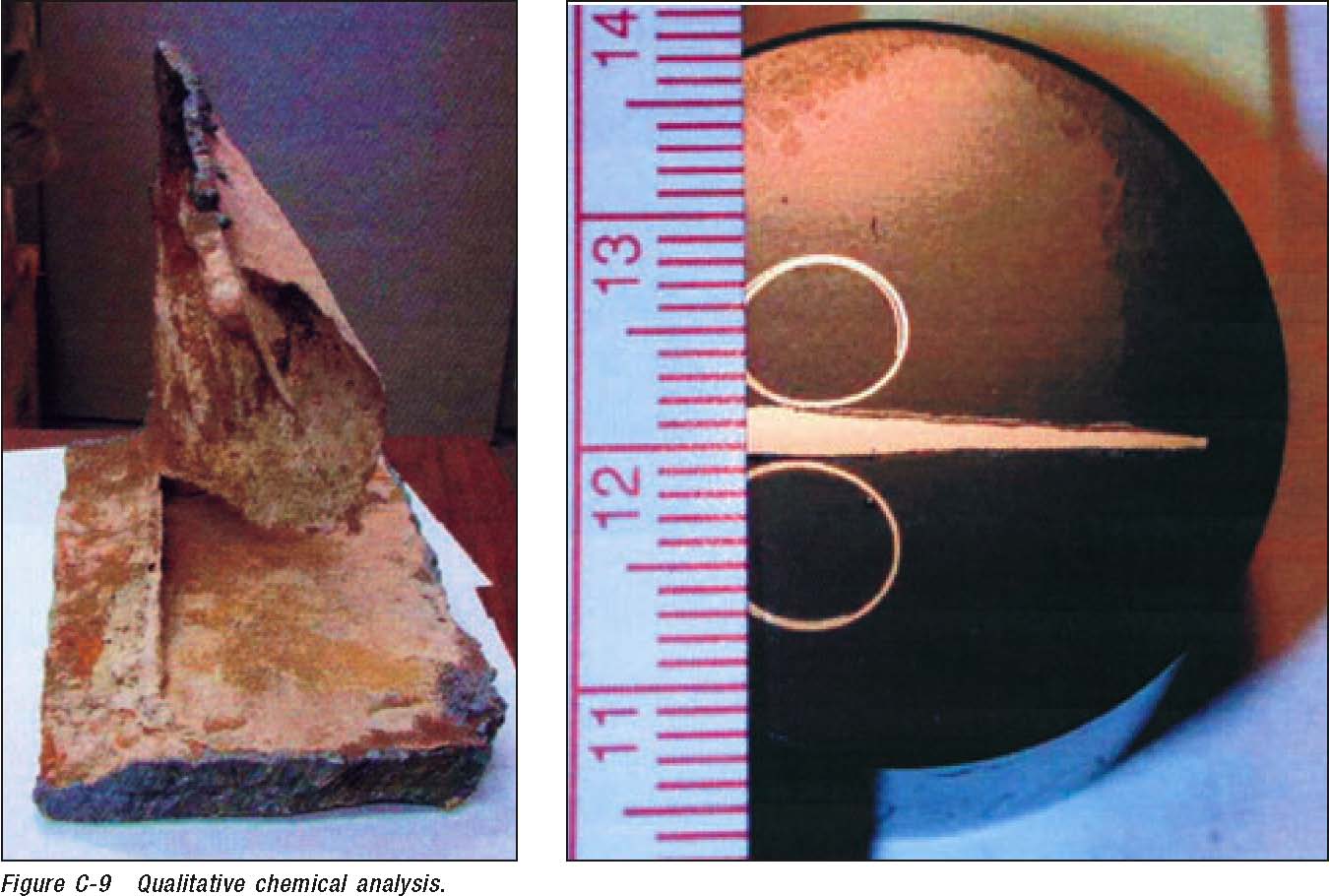

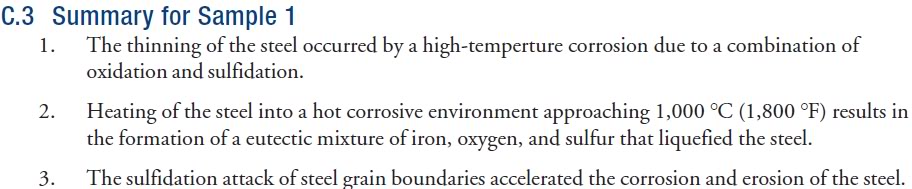

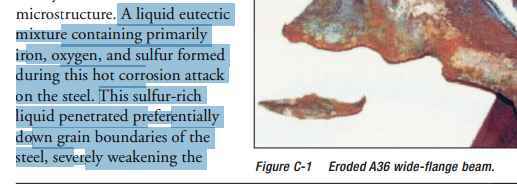

The interest in the corroded steel is for safety, and was not a cause of the collapse. The corrosion most likely happened after 911. The acid rain is a valid assumption to study. Reading the report shows steel already corroded would be more likely to suffer the corrosion attack in the fires after the collapse. Steel with no prior corrosion would have primer/coatings to protect from corrosion. Acid rain is a valid research tangent, whereas CD is not; and not supported by this report.

Where does 911 truth fantasy CD plot purchase silent no blast effects magic explosives which cause corrosion to steel which mimics what the study found? Magical explosives, where does 911 truth get them.

We do know the source of the eutectic attack, it is in the paper; albeit you want different level of abstraction (does your cause of the corrosion have match scientifically); I understand we don't know what in the WTC contributed to the, Oxygen (oops, thousands of things, ignore air, it will help to ignore the report conclusion, of corrosion), and the things with sulfur compounds in them (oops, thousands more, but ignore them). You can't dismiss possible pre 911 corrosion from acid rain (what did you call it), or leaks of substances, which could corrode the steel before 911, which help contribute to a more rapid corrosion in the pile after 911.

The report clearly shows no signs of CD for the steel studied; and no damage from explosives found on any steel. The scientist were hot to study any interesting steel, where is the evidence for CD? Not in this thread. NOt in this report.

You posted videos of gravity collapses started by explosives, debunking CD is the only way buildings fall. The explosives don't make the building fall rapid, gravity does, and explosives don't leave corrosion at 1000 and 800 C. Then the 67 percent right, 33 percent wrong "expert", who says no CD on the towers. Explosives start the collapse in seconds, gravity does the rest; fire caused failure of steel, gravity does the rest. Why are the fantasy explosives so slow on 911 to make the building collapse? Where do you find explosives which are not cooked off in fire? Another magical feature of fantasy CD, explosives which are fire proof, and fuses, fireproof.

What caused the corrosion in the CD fantasy 911 truth version of 911? What is your cause for the corrosion?

https://www.fema.gov/media-library-data/20130726-1512-20490-8452/403_apc.pdf